Mercury-free high-pressure discharge lamp with a reduced amount of zinc halide

A technology for high-pressure discharge lamps and content, which is applied to discharge lamps, gas discharge lamps, circuits, etc., and can solve problems such as luminous flux drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

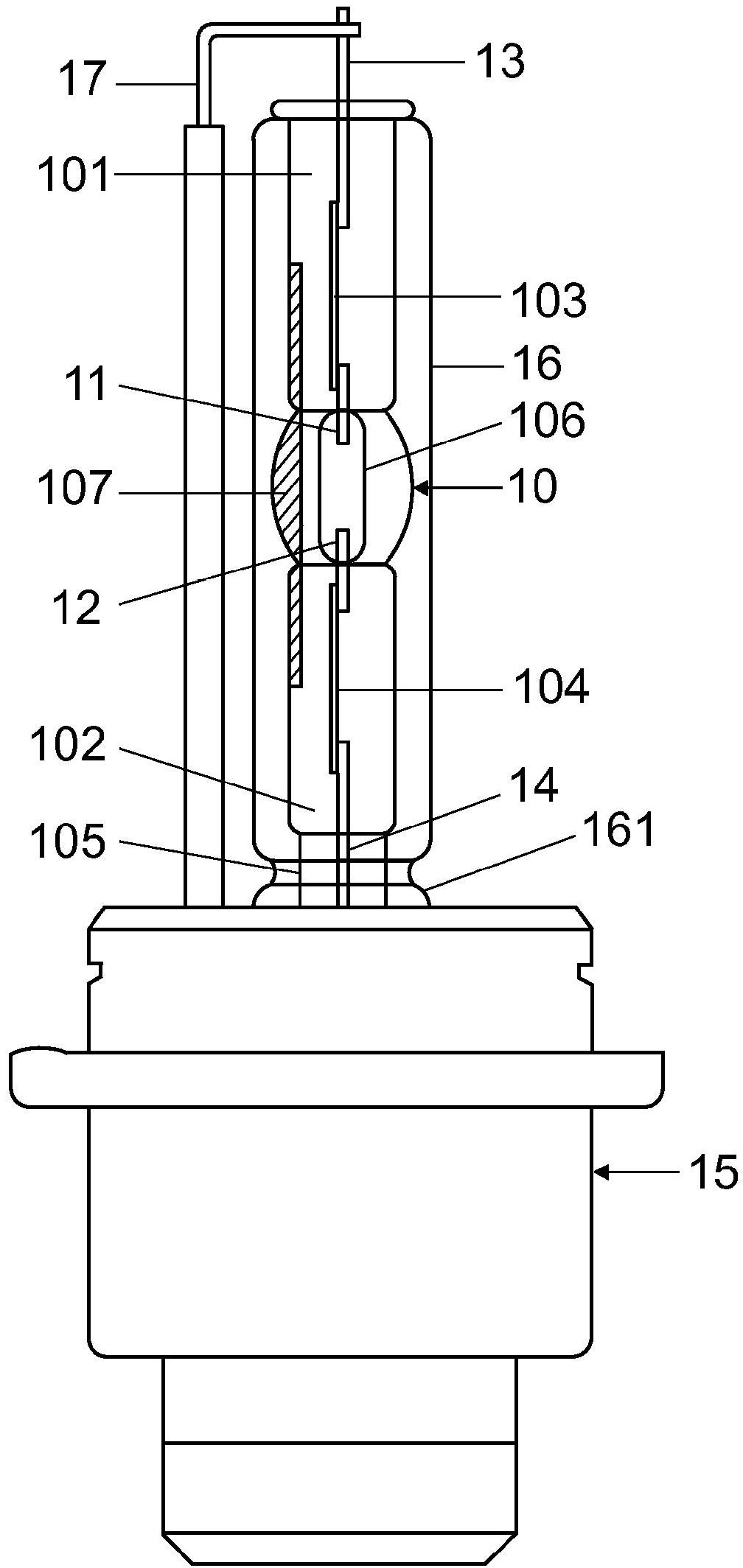

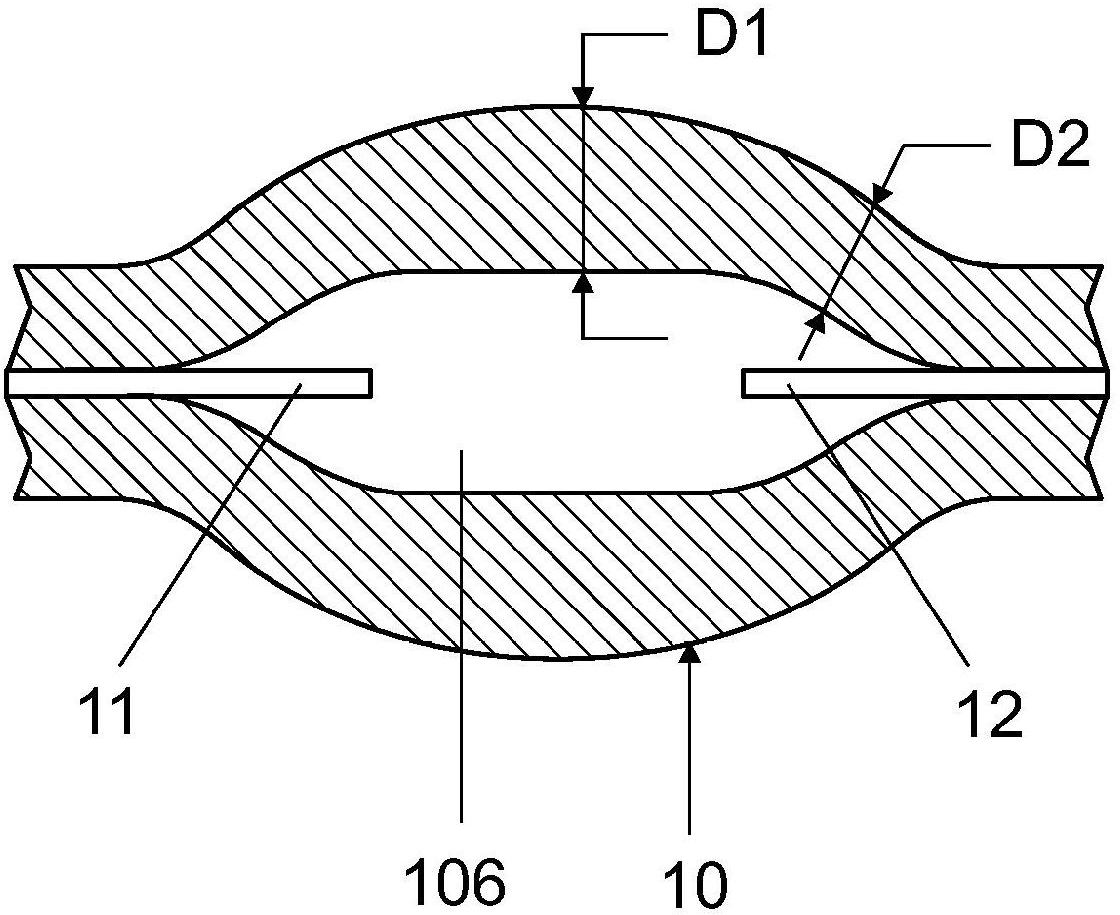

[0028]A preferred embodiment of the invention is a mercury-free halide metal vapor high-pressure discharge lamp with an electrical power consumption of 25 watts. The lamp is designed for use in motor vehicle headlights. The high pressure discharge lamp has a 17mm 3 Discharge vessel 10 , sealed on both sides, of a volumetric discharge space 106 in which an ionizable filling is contained in a gas-tight manner. In the region of the discharge space 106, the outer contour of the discharge vessel 10 forms an ellipsoid, and its inner contour forms a cylinder in the region between the electrodes 11, 12 ( figure 2 ). The walls of the discharge vessel 10 are thus convexly arched in the region of the discharge space 106 and have a greater wall thickness between the electrodes 11 , 12 than at the two ends of the discharge space 106 , at Electrodes 11, 12 are provided in the two ends. The ratio D1 / D2 of the wall thickness lies in the range of 1.2 to 1.3. That is to say, the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com