Precise push-pull wire-feeding device

A wire feeding device, push-pull technology, applied in the field of push-pull wire feeding device, can solve the problems of difficult to achieve wide application in the market, high price, etc., and achieve the effect of overcoming spot pressure, reducing workload, and increasing arc voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

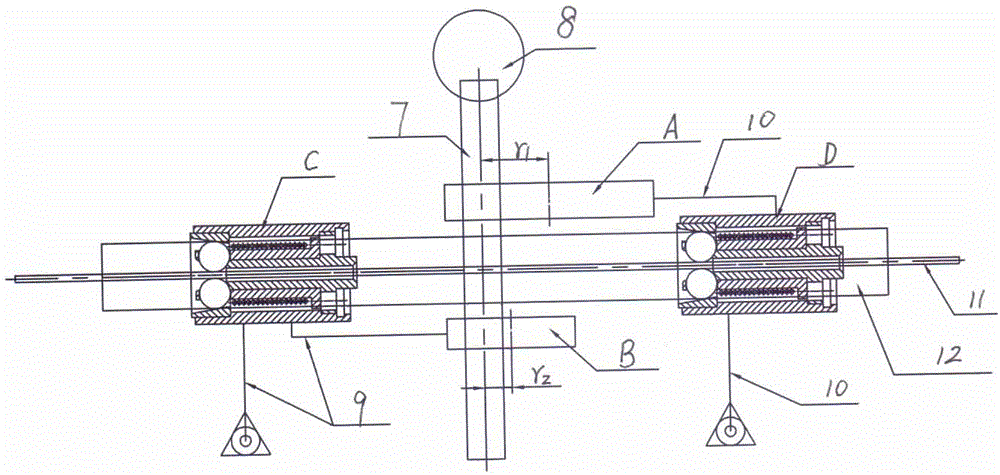

[0020] A precision push-pull wire feeding device includes a double crankshaft 7, one end of the shaft is connected with a motor 8, and there are two eccentric cams A and B in the same direction on the shaft. The eccentric radius of cam A is r 1 , the eccentric radius of cam B is r 2 , r 1 ≠ r 2 , Two or more three-ball wire feeding chucks are arranged front and back, and are connected to cam A and cam B with different movable connecting rods 9 and 10 respectively; the number of movable connecting rods is not limited. When the motor rotates, the eccentric cam rotates, and each three-ball wire feeding chuck moves back and forth synchronously with the eccentricity under the support of different movable connecting rods, and the distance of the forward and backward movement is equal to twice the eccentric radius;

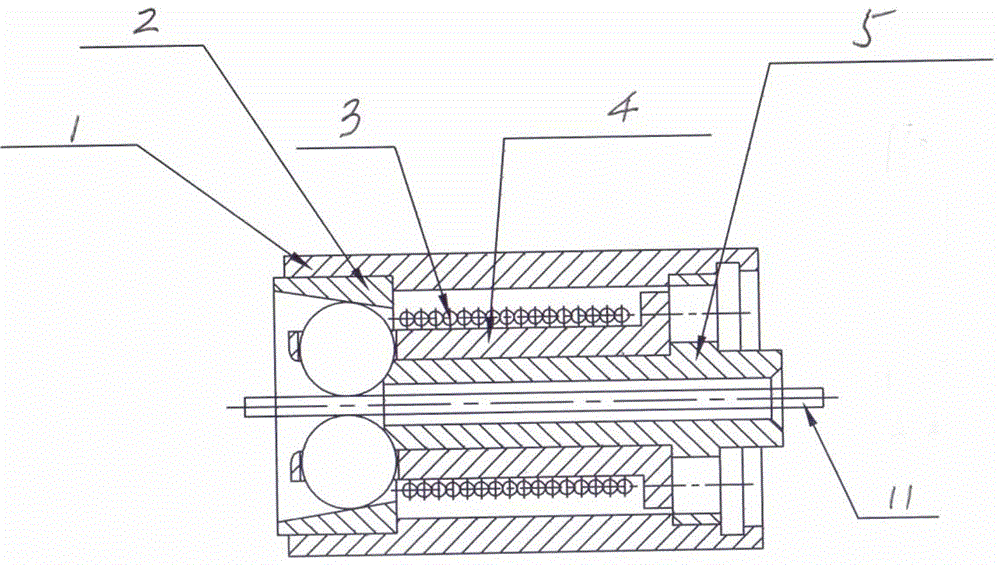

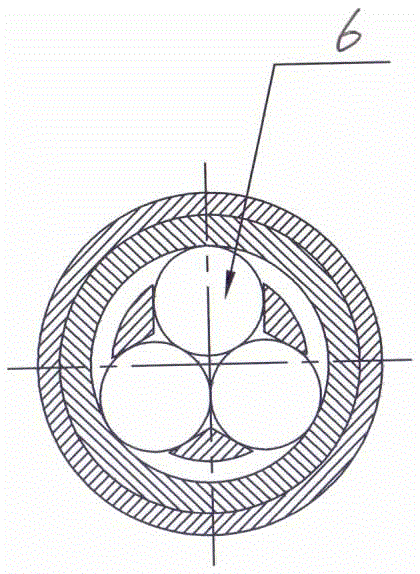

[0021] The three-steel ball wire feeding chuck includes a cylindrical sleeve 1, a steel ball cage 4 is arranged inside the cylindrical sleeve, a three-steel ball mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com