Respirator and softener assembly for dish washing machine

A technology of dishwashers and soft components, which is applied to tableware washing machine/rinsing and washing machine parts, tableware washing machine/rinsing machine, applications, etc. It can solve the problem of large installation space, small dishwashers that cannot be installed with water softeners, Solve problems such as the complex structure of dishwashers, and achieve the effects of saving space, improving assembly efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

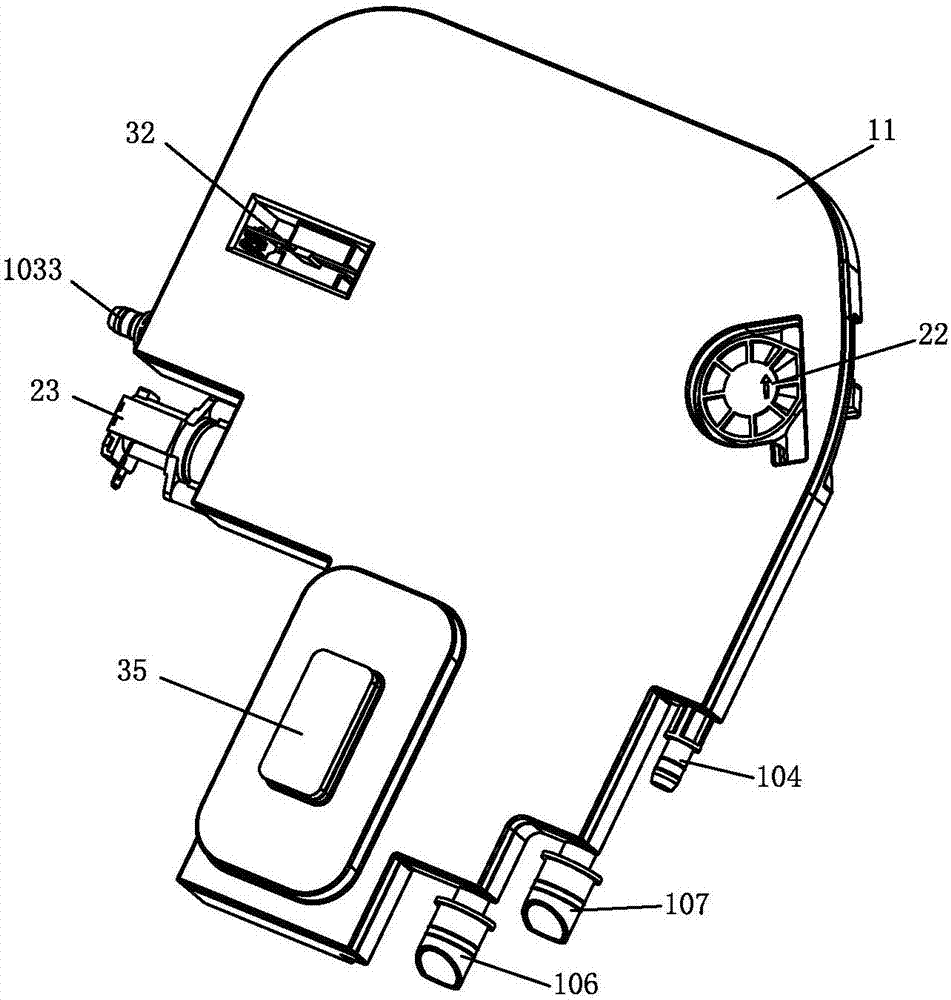

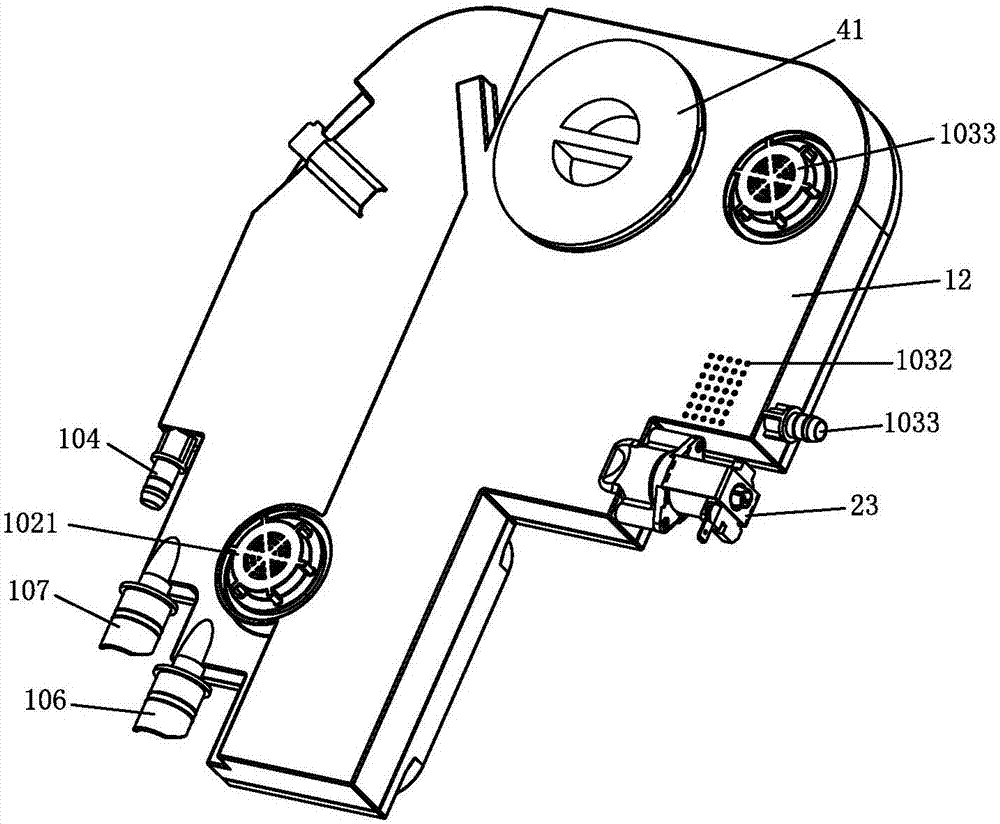

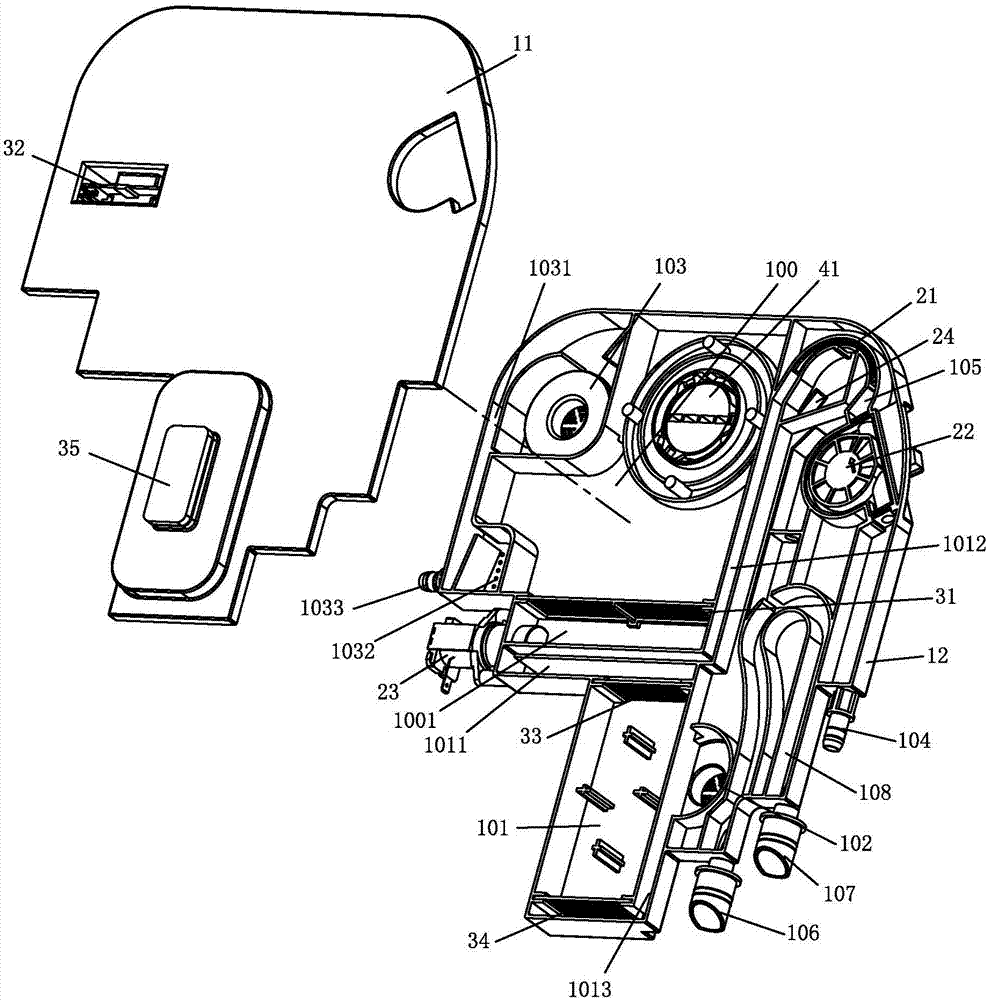

[0030] see Figure 1-Figure 3 , the soft water assembly for the dishwasher includes a main body composed of an upper soft film 11 and a lower soft film 12, a salt chamber 100 and a resin chamber 101 are arranged adjacent to each other in the main body, and the soft water outlet corresponding to the resin chamber 101 is provided on the main body The end 1013 is provided with a water inlet port 102 , and the position corresponding to the salt chamber 100 is provided with a respirator port 103 . The upper flexible sheet 11 and the lower flexible sheet 12 are welded together by hot plate welding, and form a main body after welding. The main body integrates a water softener (salt chamber 100 and resin chamber 101), a water inlet (water inlet interface 102) and The respirator (respirator interface 103) makes the main body constitute a highly integrated breathing soft assembly, which greatly saves space. Bowl machines, small dishwashers, etc. cannot be installed with water softeners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com