Security industry camera core assembly based automatic assembly system and method

A core component and assembly system technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as people are prone to fatigue, work is boring, and the process of taking and screwing screws is not smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

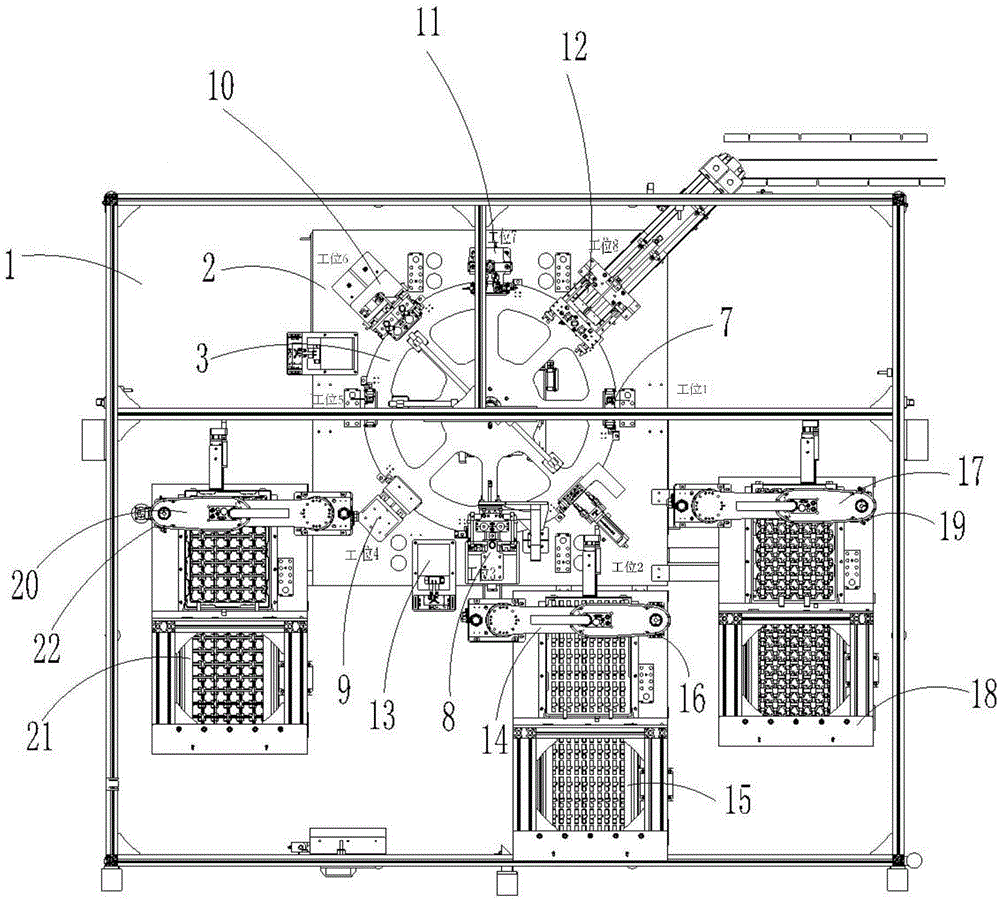

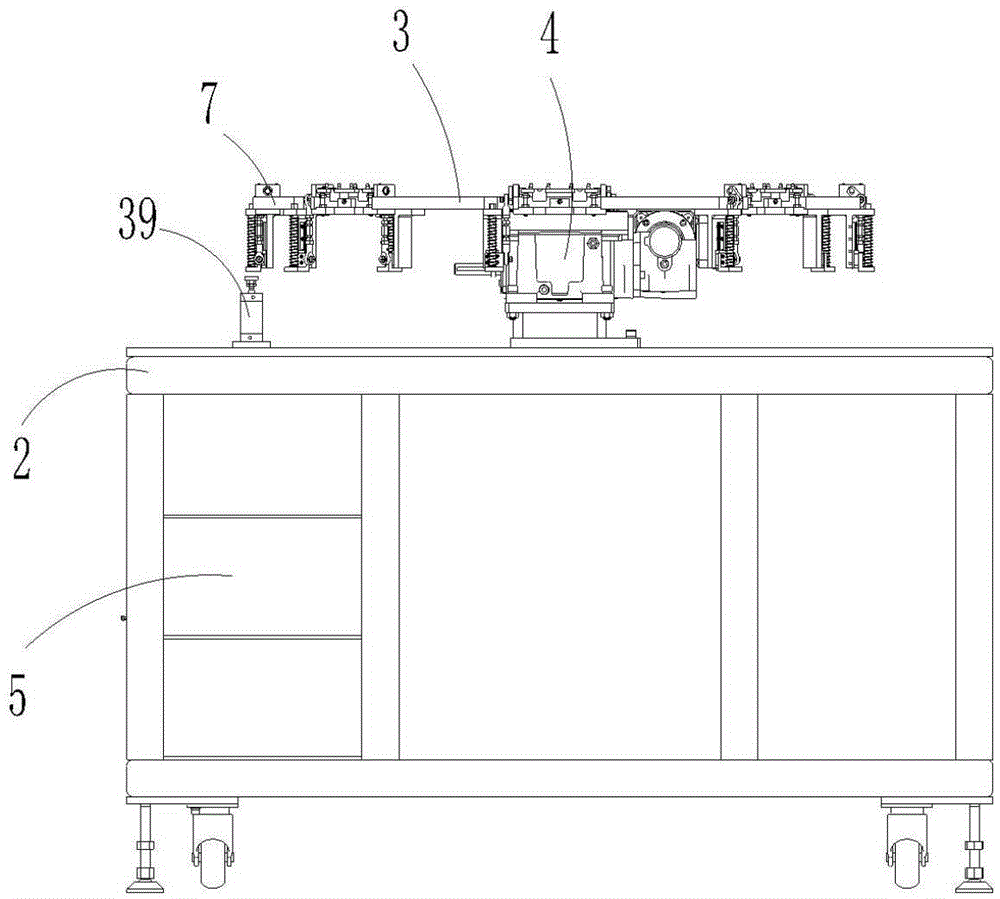

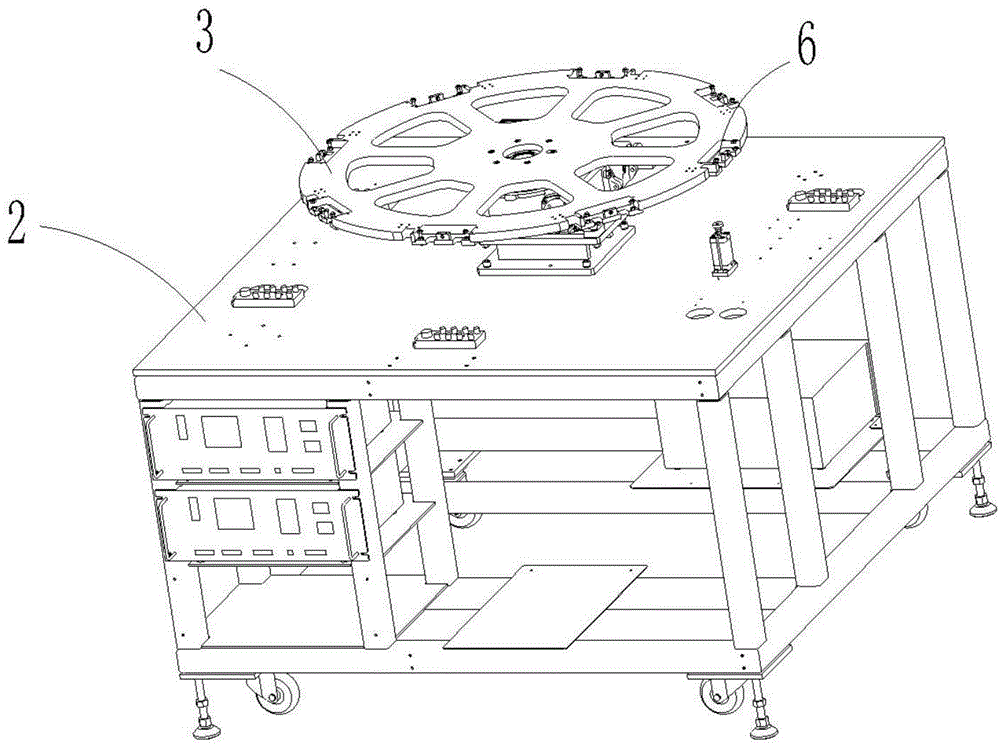

[0118] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 and Figure 29 As shown, an automated assembly system based on the core components of the camera in the security industry includes an operating area 1, an operating frame 2 is provided in the operating area 1, and an operating frame 2 is fixed above the operating frame 2. operation disk 3, the rotation of the operation disk 3 is controlled by an indexer 4, a controller 5 is provided in the operation frame 2, and at least 6 evenly distributed The operating position assembly 6, the operating position assembly 6 is provided with a reversible positioning jig 7, and the lenses in the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com