Pot cover assembly and pressure cooker

An electric pressure cooker and lid technology, which is applied in the field of pressure cookers, can solve the problems of complex structure, high cost, inconvenient use, etc. of the electric pressure cooker, and achieve the effects of simple and reliable structure, low cost and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

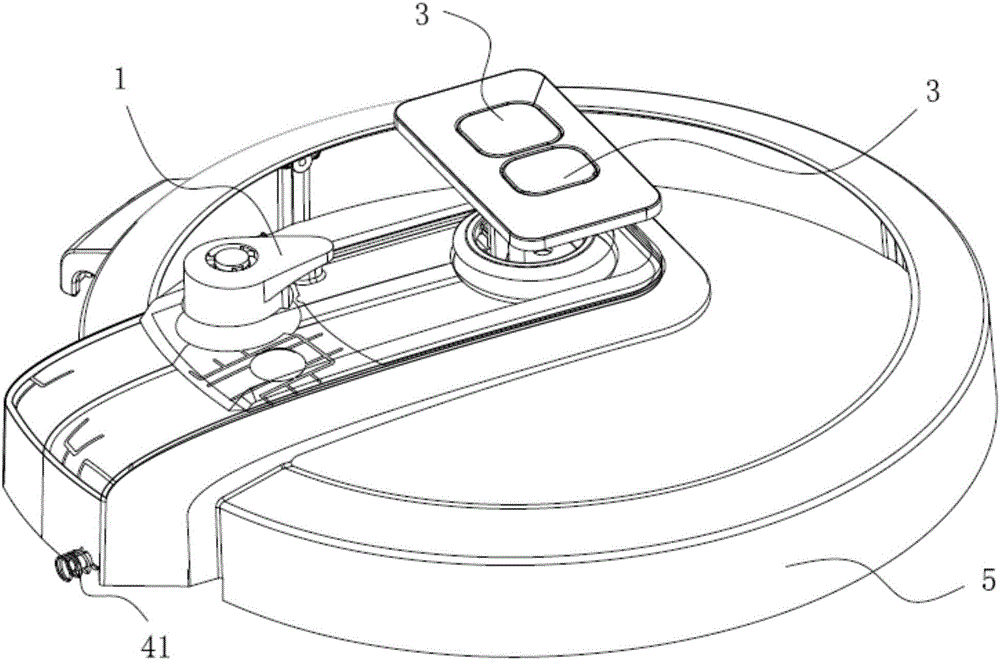

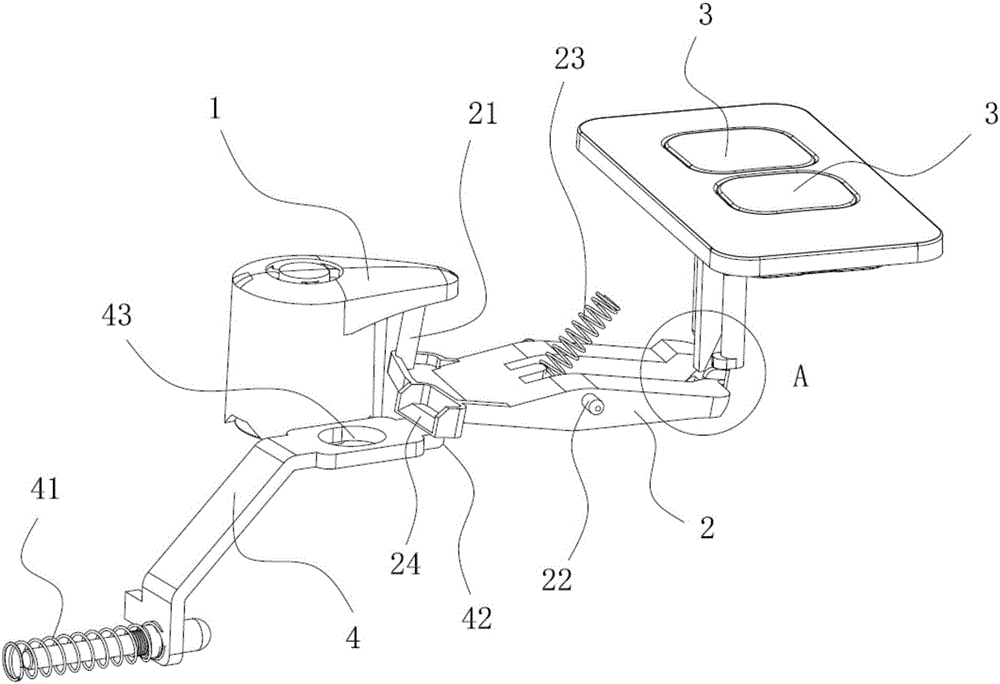

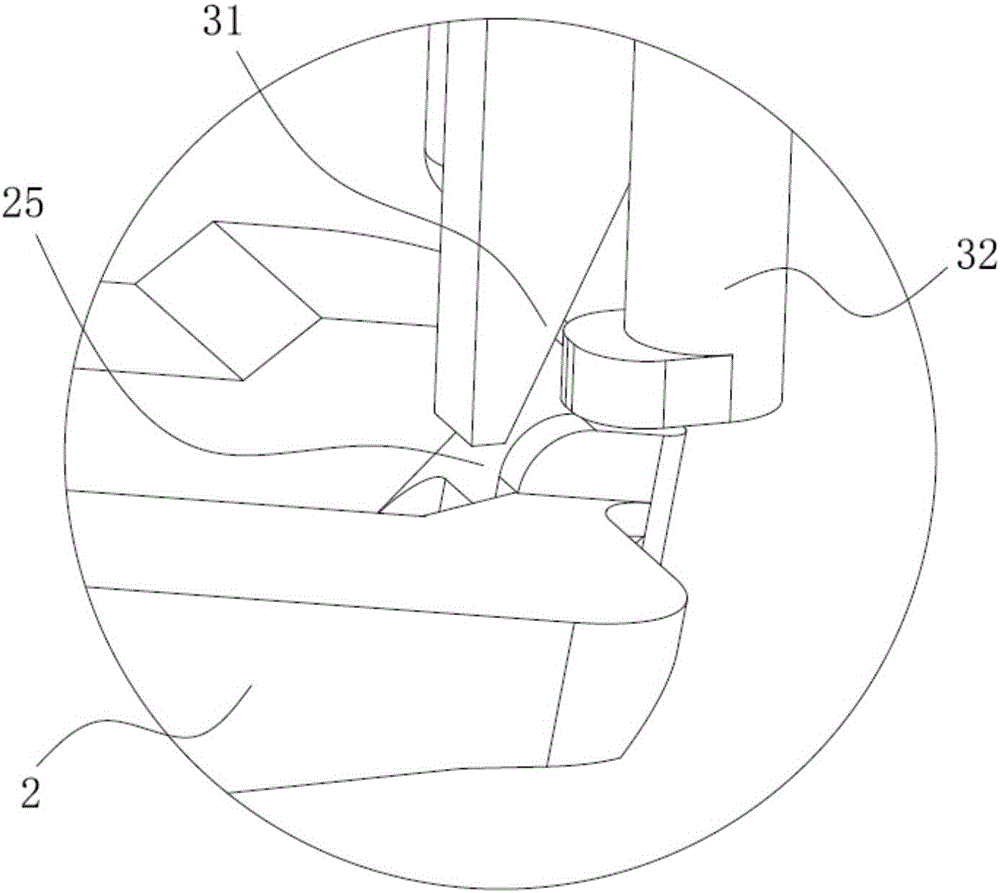

[0038] The preferred embodiment discloses a pot cover assembly. like figure 1 As mentioned above, the pot cover assembly includes a pressure limiting valve 1 and a valve body imbalance mechanism. After the valve body imbalance mechanism is triggered, it can continuously lift the pressure limiting valve 1, so that the pressure limiting valve 1 continues to be in the exhaust state until the valve body imbalance mechanism is activated. Reset, the electric pressure cooker returns to high pressure mode. Among them, the method for the valve body unbalance mechanism to be reset includes but is not limited to pressing the reset button, opening the pot cover of the electric pressure cooker or rotating the pot cover; The gas state does not include the working state where the pressure limiting valve 1 is slightly unbalanced but not exhausted due to the action of the sealing device.

[0039] This electric pressure cooker includes a high-pressure mode and a pressure-free cooking mode, an...

Embodiment 2

[0059] This preferred embodiment discloses a pressure cooker, which includes the pot cover assembly as described in the first preferred embodiment. It can be manually exhausted for a short time or continuously to achieve pressure-free cooking mode. It has full functions and is easy to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com