Non-contact engine turbine blade tip radial gap measurement method

A radial gap, non-contact technology, applied in the direction of measuring devices, instruments, electrical devices, etc., can solve the problems of inability to achieve full-circle measurement, low precision, poor operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

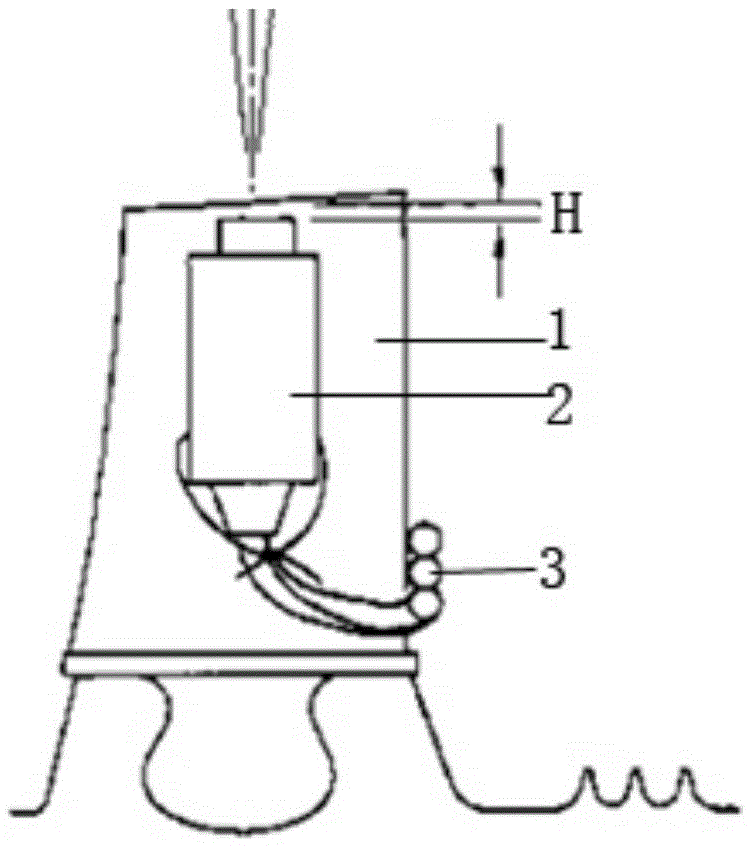

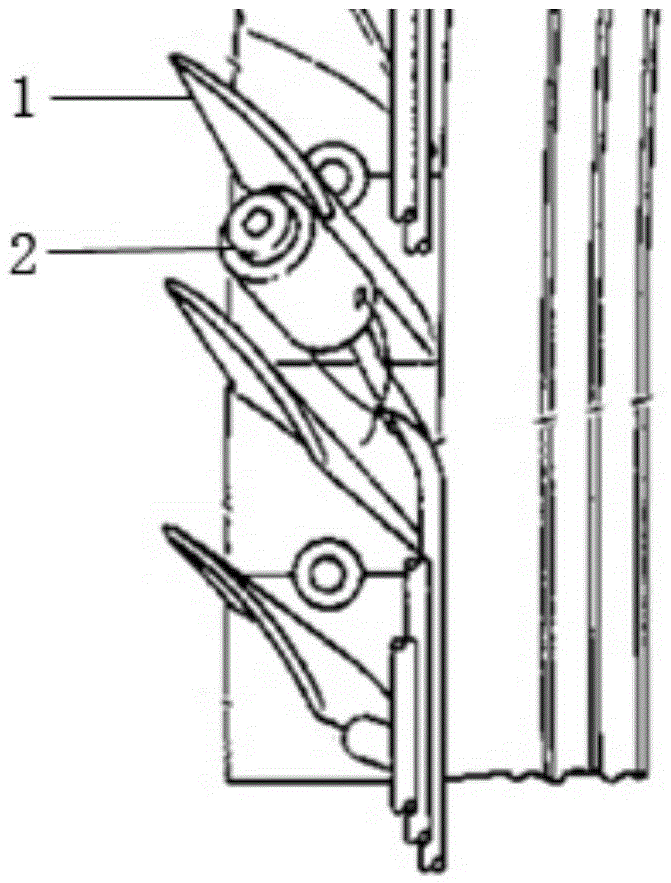

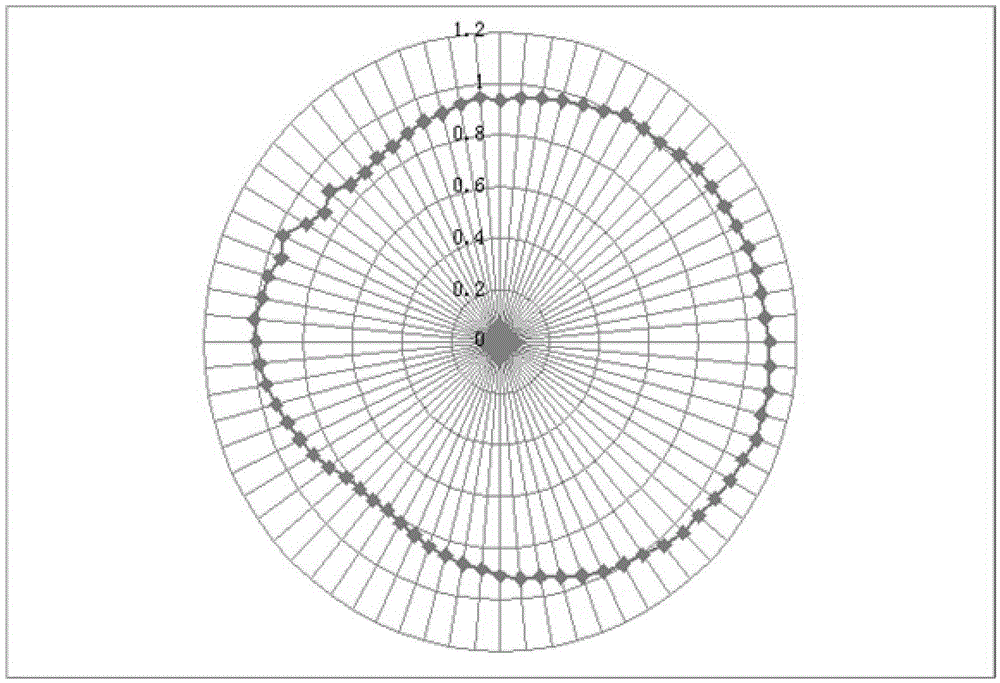

[0026] Embodiment: The high-pressure turbine blade tip radial clearance measurement system is based on the electrostatic capacity non-contact sensor. In order to ensure the surface integrity of the engine parts and the reliability of the sensor installation, the sensor is fixed on the turbine blade with PVC-based acrylic double-sided adhesive that does not damage the metal material, and the positioning surface is added on the side of the sensor head to ensure that the front end is in contact with the blade. The ends are flush. The inner ring surface of the high-pressure turbine casing and the front end of the sensor measuring head constitute the two plates of the capacitor. This capacitance value is a function of the geometry of the two plates, the distance between the plates, and the relative permittivity of the medium between the plates. If the edge effect is not considered, the relationship between the capacitance value and the distance between the two plates can be expres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com