Edge cutting machine for wood boards

An edge trimming machine and plate technology, which is applied in the field of plate processing, can solve problems such as affecting production efficiency, high labor intensity, and reducing processing accuracy, so as to reduce edge trimming steps and manual labor, reduce physical injuries, and reduce edge trimming steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

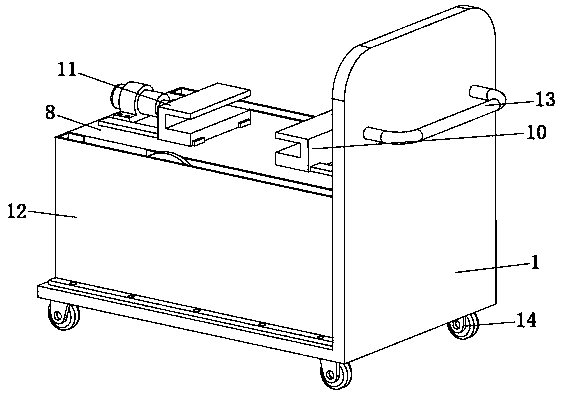

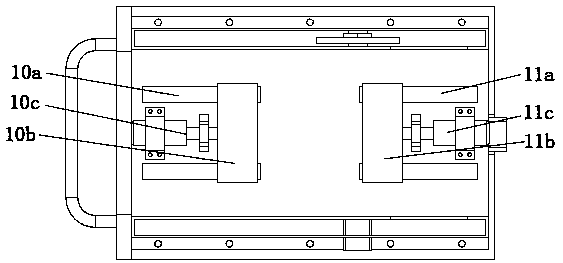

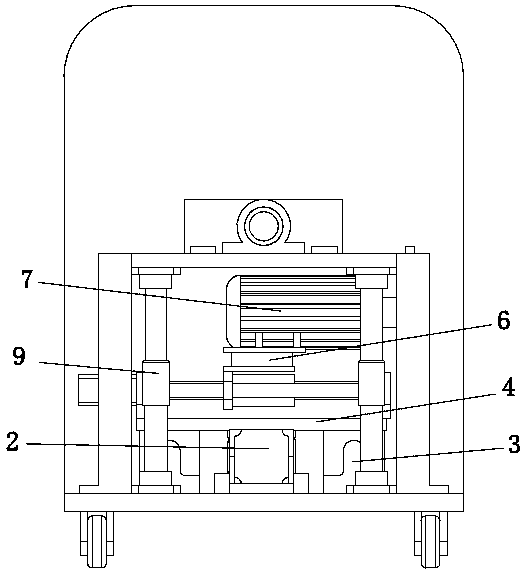

[0026] refer to Figure 1 to Figure 8 The shown edge trimmer for wood panels includes an L-shaped support plate 1, the support plate 1 includes a horizontal plate 1a and a vertical plate 1b fixedly connected to the horizontal plate 1a, and the horizontal plate 1b is formed integrally. The top of 1a is provided with a drive mechanism 2 arranged along its length direction, and the side of the drive mechanism 2 is provided with a guide assembly 3 arranged along the length direction of the horizontal plate 1a, and the top of the drive mechanism 2 is provided with a fixed connection with it. The bottom plate 4 is provided with a screw slide 5 along the length direction of the bottom plate 4, the slider of the screw slide 5 is provided with a rotating assembly 6 fixedly connected to it, and the top of the rotating assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com