Full-automatic metal sheet surface polishing device capable of adjusting precision

A metal plate and surface polishing technology, which is applied to surface polishing machine tools, grinding drives, metal processing equipment, etc. Accurate, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

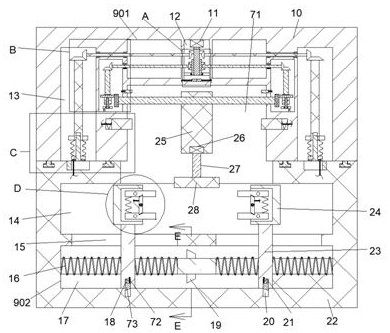

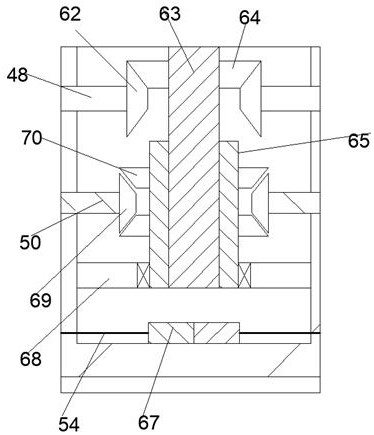

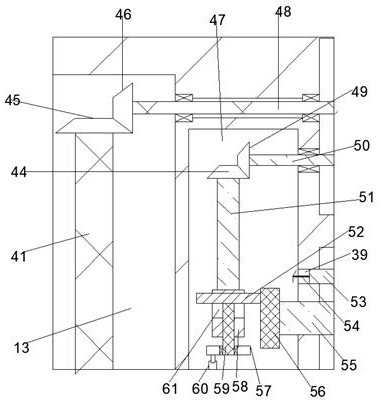

[0020] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] A fully automatic metal plate surface polishing device with adjustable precision of the device of the present invention includes a moving housing 10 and a processing device 901 located in the moving housing 10, the processing device 901 includes a power chamber 12, the The lower side of the power chamber 12 is provided with a working groove 71 with an opening downward. The mobile housing 10 is provided with two clamping devices 902 symmetrical to the left and right of the power chamber 12. The cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com