Automatic feeder of retainers

An automatic feeding and cage technology, applied in the direction of transportation and packaging, conveyor objects, etc., to improve work efficiency, save labor costs, and ensure assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

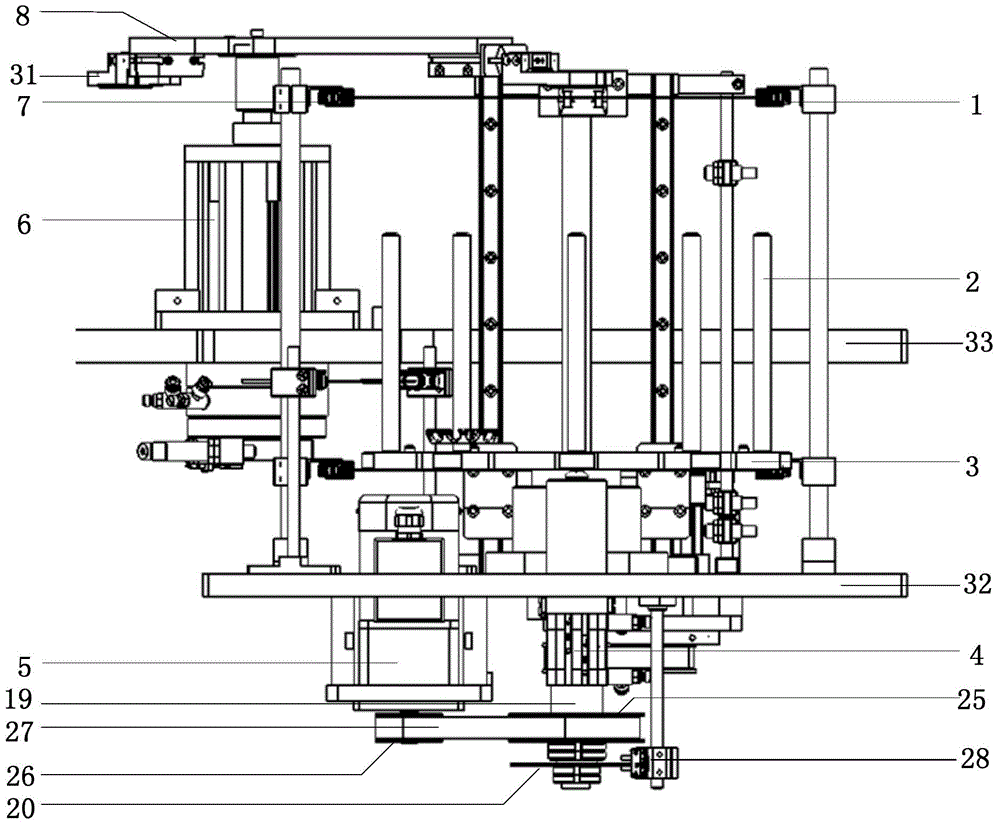

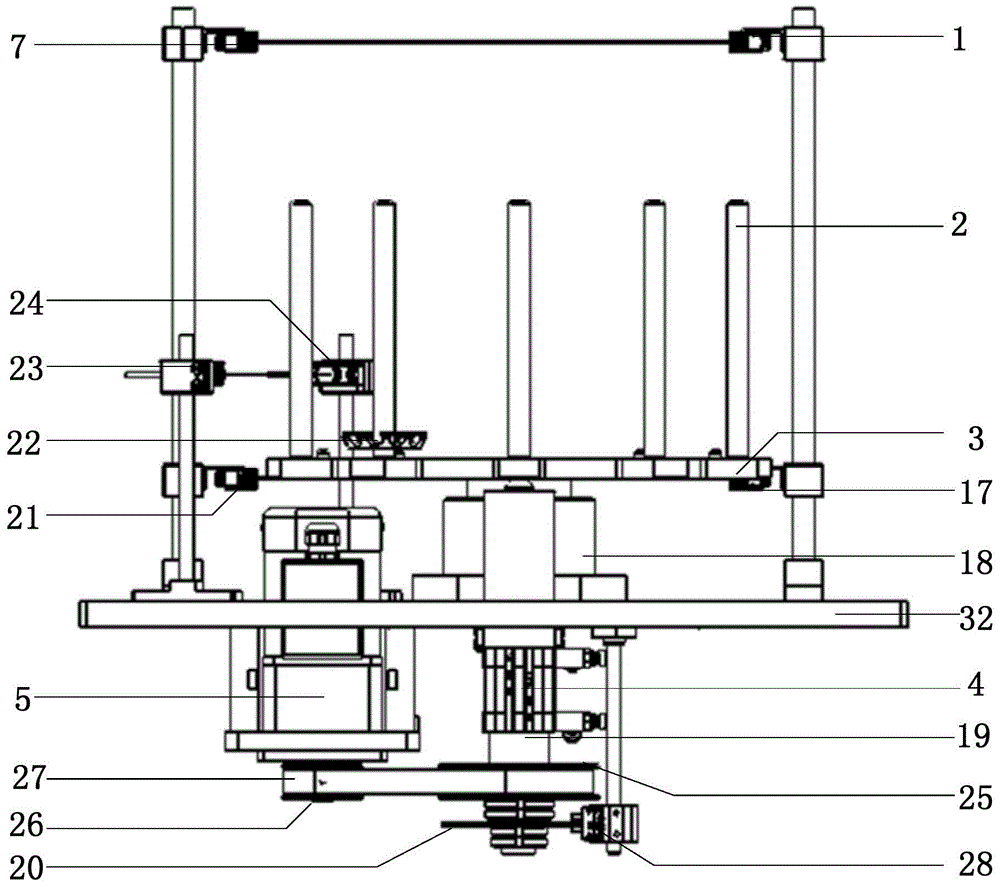

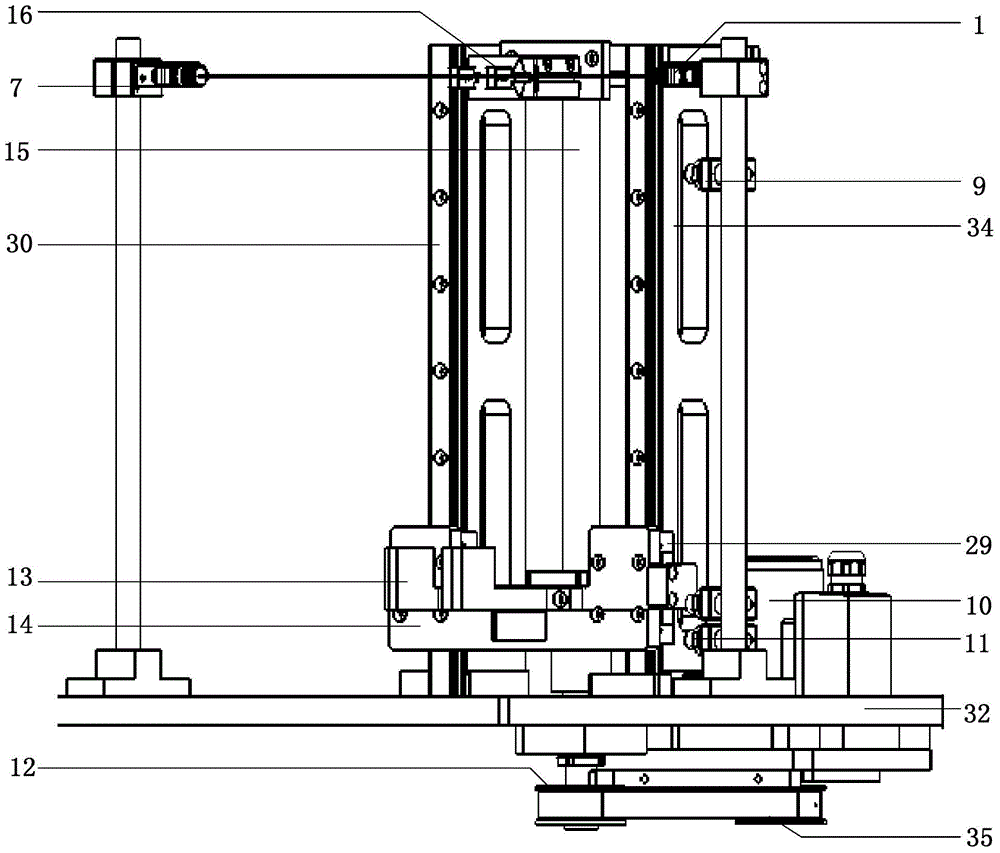

[0020] The cage automatic feeding device of the present invention mainly includes a platform, a feeding mechanism, a jacking mechanism and a pick-and-place mechanism, and the platform is provided with a lower platform 32 and an upper platform 33 (see figure 1 ), the feeding mechanism and the jacking mechanism are all installed on the lower platen 32, and the pick-and-place mechanism is installed on the upper platen 33. The feeding mechanism is located in front of the jacking mechanism, and the pick-and-place mechanism is located on the upper side of the jacking mechanism.

[0021] Such as figure 1 and figure 2 As shown, the feeding mechanism includes a feeding turntable 3, a rotating shaft 19 and a rotating mechanism. There are many (ten in the figure) central rods 2 evenly distributed on the feeding turntable 3, and the central rods 2 are used to insert the material column filled with the cage 22. The feeding turntable 3 is installed on the rotating shaft 19, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com