Automatic bottle cap and top cap positioning and assembly line and operation method thereof

An assembly line and automatic positioning technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency and inapplicability, and achieve the effect of improving assembly efficiency and ensuring assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

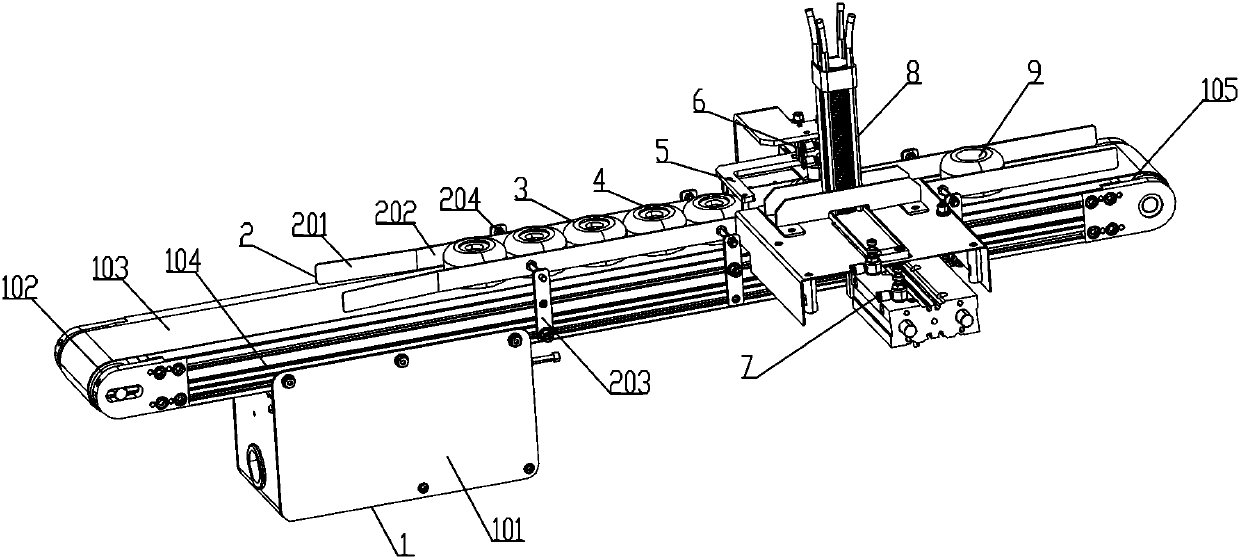

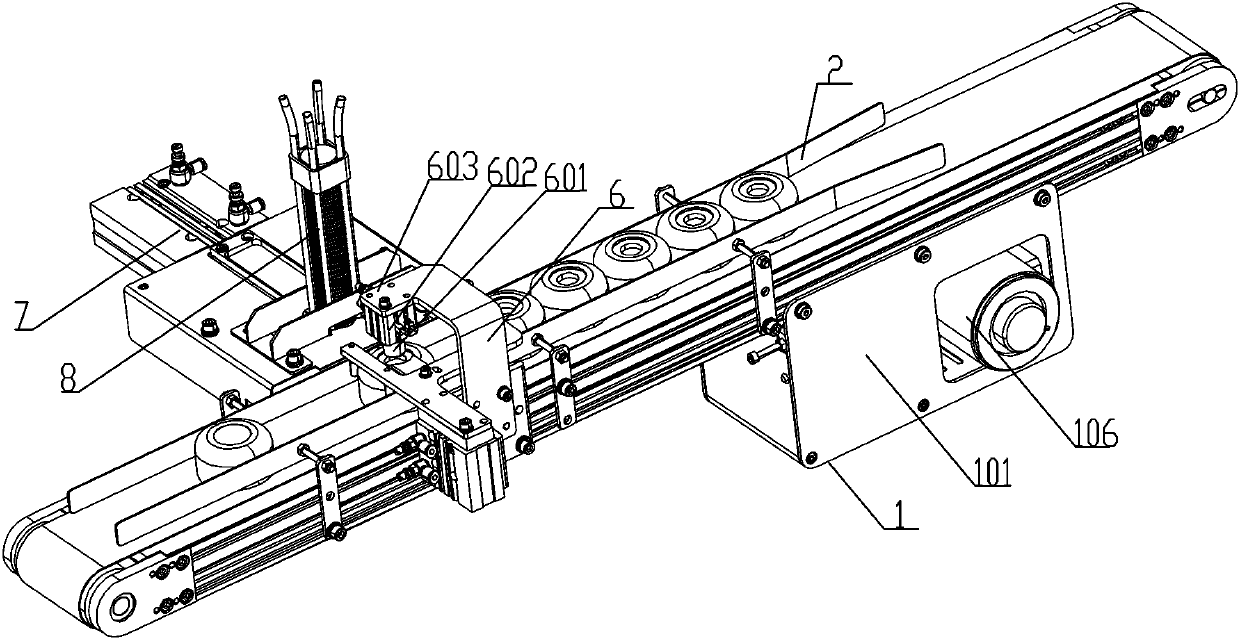

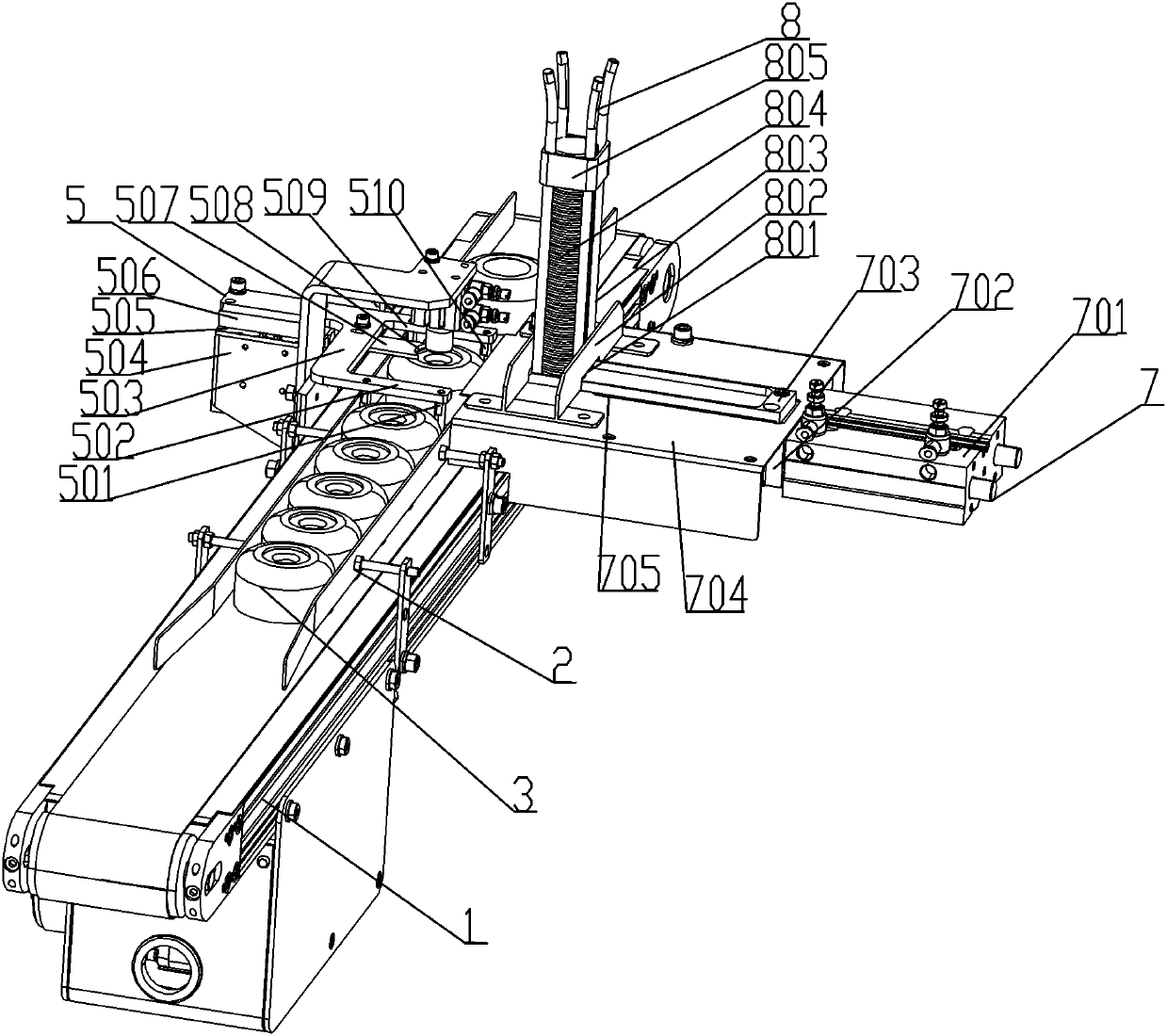

[0041] see Figure 1-4 , bottle cap top cap automatic positioning assembly line, which includes a conveyor 1 for conveying bottle caps, the feed end of the conveyor 1 is provided with a feed guide structure 2, and the end of the feed guide structure 2 is provided with a useful For the positioning mechanism 5 for positioning the wine cap, one side of the location of the positioning mechanism 5 is equipped with a pushing device 7 for pushing the loading of the top cover, and the pushing device 7 is used for storing the top cover. The storage mechanism 8 cooperates to realize the automatic upper cover, and the other side of the position of the positioning mechanism 5 is equipped with a press-fitting mechanism 6 for press-fitting the top cover. This assembly line can be used for automatic press-fitting and assembly of the cover plate on the top of the bottle cap, and can automatically position and press-fit it, thereby greatly improving its assembly efficiency and ensuring the ass...

Embodiment 2

[0051] The operation method of the automatic positioning assembly line for the top cap of the bottle cap comprises the following steps:

[0052] Step 1: Store the top cover 804 to be assembled between the columns 803 of the storage mechanism 8;

[0053] Step 2: Start the conveyor 1, convey the bottle cap 3 through the conveyor 1, and the bottle cap 3 enters the positioning mechanism 5 through the feeding guide structure 2;

[0054] Step 3: Start the positioning mechanism 5, drive the positioning lifting plate 503 to lift through the positioning lifting cylinder 505, and then drive the corresponding head stopper column 501 and tail stopper column 510 to realize lifting, and then limit the position of the bottle cap 3 to make it positioned on the conveyor belt 103;

[0055] Step 4: After the bottle cap 3 is positioned, start the pushing device 7, push the top cover push plate 703 through the push material cylinder 701, and then push the top cover 804 stored in the storage mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com