Automatic assembly line for automobile seats and assembly method

An assembly line, car seat technology, applied in the direction of assembly machines, vehicle parts, transportation and packaging, etc., can solve the problems of low assembly efficiency, missing assembly, high labor intensity of assembly, and achieve less error and missing assembly, and reduce labor Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

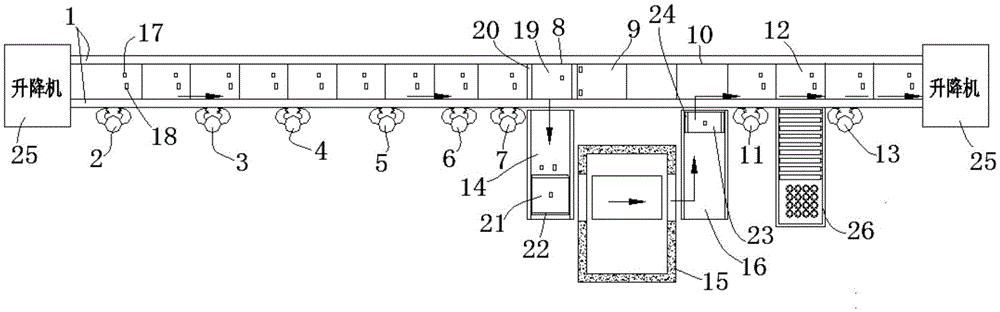

[0039] Such as figure 1 As shown, the automated car seat assembly production line includes a workbench and a conveyor chain 1 arranged on both sides of the workbench. On the workbench are slide rail assembly assembly station 2, seat cushion assembly assembly station 3, and backrest assembly station. Assembly assembly station 4, guard plate seat belt buckle assembly station 5, headrest assembly station 6, wiring harness finishing station 7, first transfer station 8, transition station 9, second transfer station 10. Appearance and function inspection station 11, rework station 12 and packaging station 13; the side of the first transfer station 8 is provided with a noise detection and delivery workbench 14 on the side leading to the sound insulation test room 15, and the sound insulation test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com