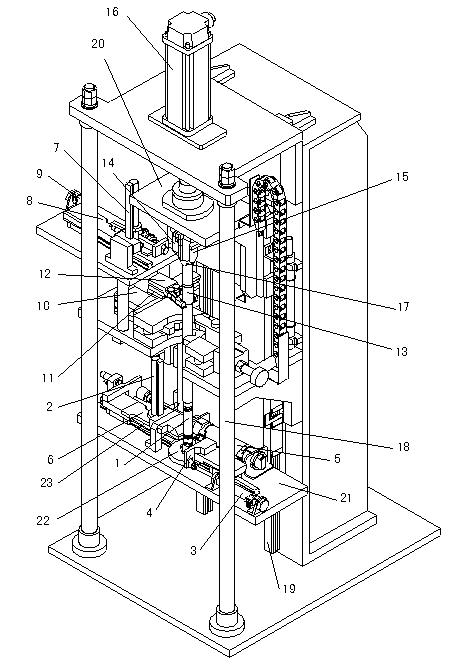

Apparatus for pressing clamp springs and spider on shaft lever of constant speed shaft

A technology of circlips and shafts, applied in metal processing equipment, assembly machines, metal processing, etc., can solve problems such as complex structure, inconvenient maintenance, inapplicable installation of circlips on shafts, etc., to ensure assembly quality and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention, as shown in the drawings, comprises a support 18, an upper seat 20 and a lower seat 21, a vertical guide rail 19 is installed on the support 18, the upper seat 20 is installed on the vertical guide rail 19, and the lower seat 21 is fixedly installed on the support 18 bottom of. Between the upper seat 20 and the lower seat 21, there is a clamping cylinder 10 for clamping the constant velocity shaft rod 1. The clamping cylinder 10 is fixed and installed on the bracket 18 horizontally, and its position should ensure that the constant velocity shaft rod 1 is clamped. It does not affect the assembly of the fixed end circlip, tripod and movable end circlip. One side of the clamping cylinder 10 is provided with the lift cylinder 11 installed on the support 18, and a finger cylinder 12 is installed on the piston rod of the lift cylinder 11, and the finger cylinder 12 is used to take the jump spring and stretch the frock 13. Jump ring str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com