Spring clip automatic assembling machine

An automatic assembly machine and clip technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as difficulty in the compression of torsion springs, broken splints, production safety, etc., to reduce labor intensity and labor costs for workers, and ensure firm and reliable positioning , Good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

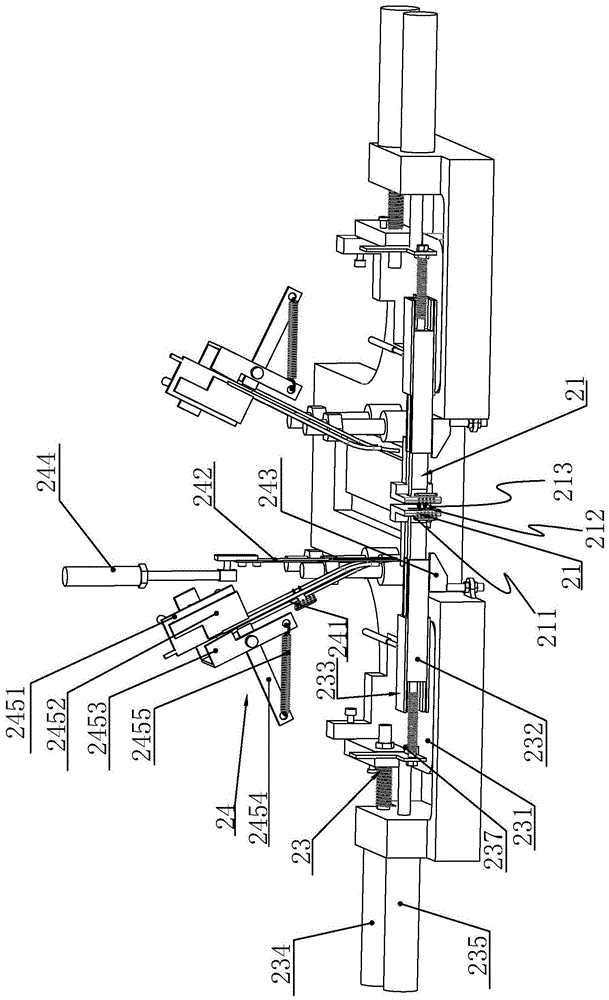

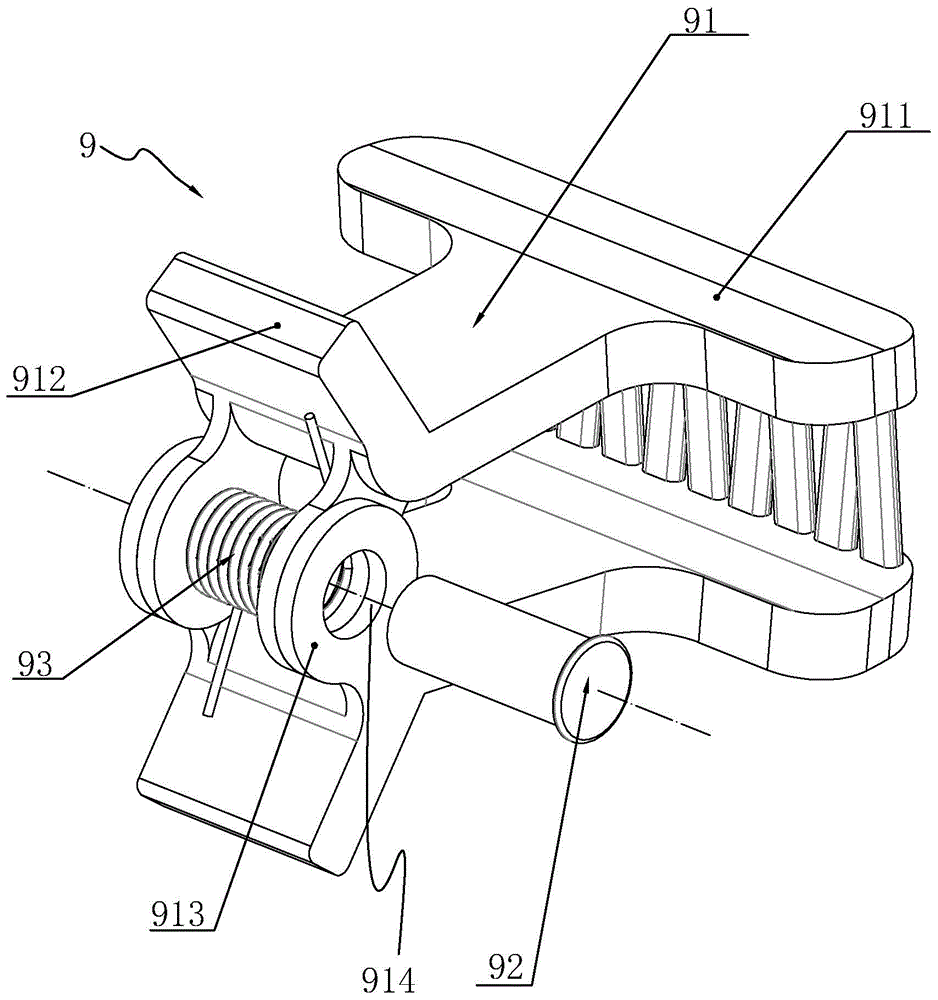

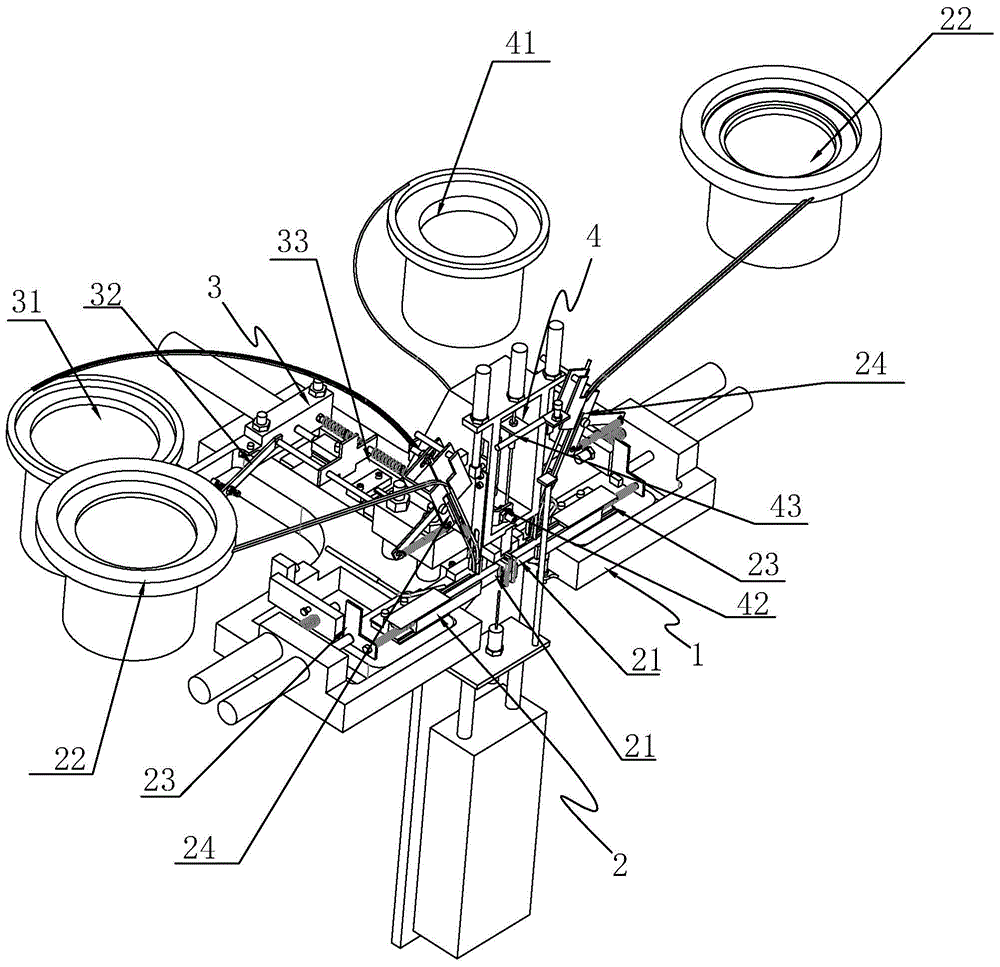

[0038] Such as Figure 2 to Figure 10 As shown, a spring clip automatic assembly machine disclosed in the present invention includes a frame 1, and the frame 1 is provided with a splint splicing device 2, a torsion spring pressing device 3 and a pin insertion device 4, and the The splint splicing device 2 includes a plywood splicing seat, and the plywood splicing seat includes two oppositely arranged splint clamping seats 21, the plywood clamping seat 21 is provided with a splint plate body positioning cavity 211 and a pivoting ear extension port 212, and the two splint clamps Between the holders 21, there are intervals between the pivoting ears 913 on the splint 91 to form a pivoting ear joint spacer cavity 213, and the pivotal ear extension port 212 communicates with the pivotal ear joint spacer cavity 213 and the splint plate body positioning cavity 211. The splint splicing seat is provided with a splint plate body positioning cavity 211 connected to the splint, the pivoti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com