Lamp wick transferring device

A transfer device and wick technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unreliable insertion, low processing efficiency, high labor cost, etc., reduce labor and labor intensity, improve processing efficiency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

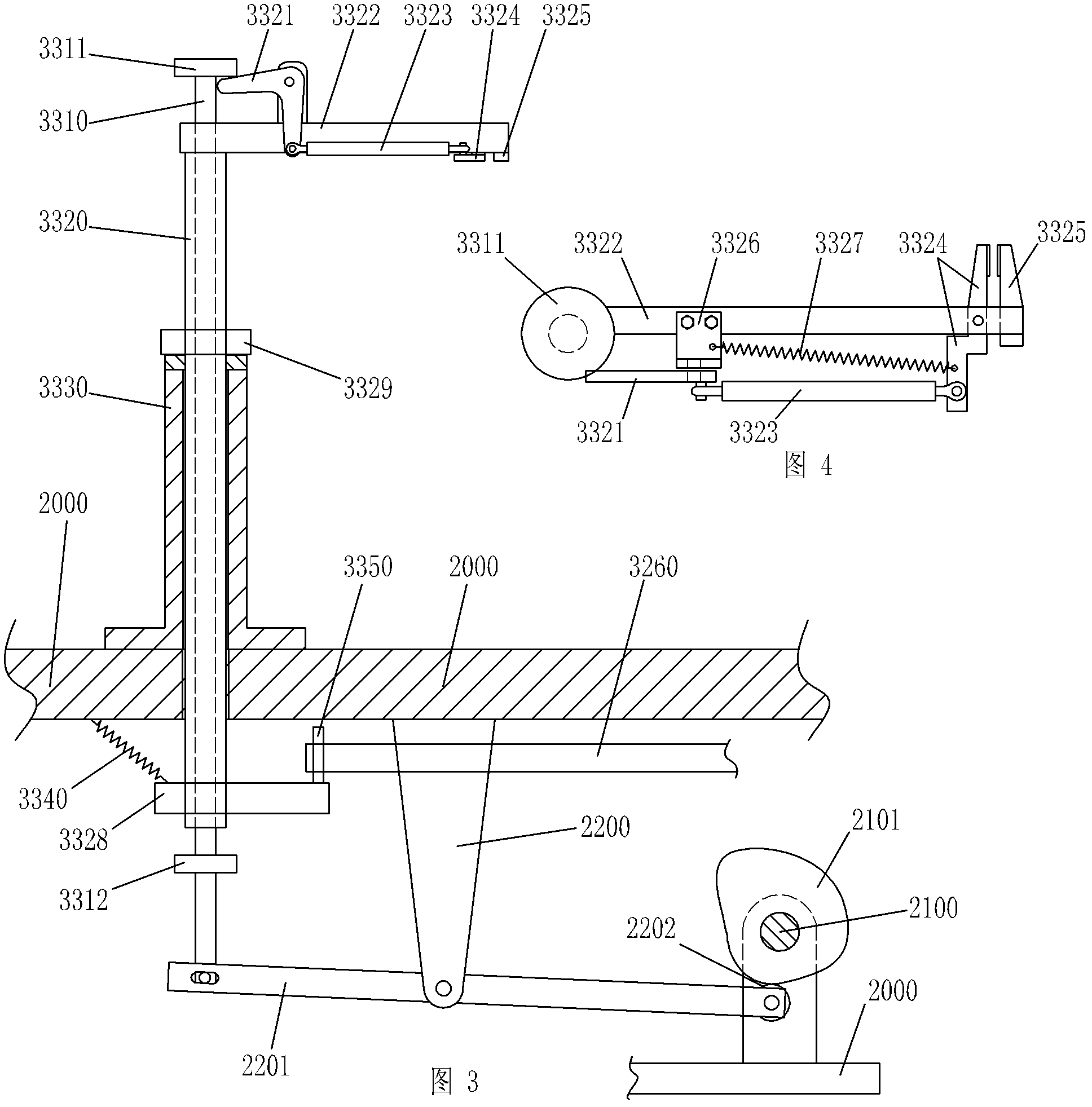

[0014] Such as image 3 , Figure 4 The wick transfer device shown includes a core rod 3310 and a sleeve rod 3320 sleeved outside the core rod 3310. A cross bar 3322 is fixed on the top of the sleeve rod 3320, and a pair of rods capable of clamping the wick are installed on the front end of the cross rod 3322. Fixed claw 3325 and movable claw 3324, fixed claw 3325 is fixed on the cross bar 3322, movable claw 3324 is hinged with cross bar 3322, and cross bar 3322 rear portion is fixed with fixed block 3326, and a pusher 3321 is installed on the fixed block 3326, pusher 3321 is hinged with the fixed block 3326 and can swing in the vertical plane. One swing end of the pusher 3321 is connected with the non-clamping end of the movable claw 3324 through the connecting rod 3323, and the other swing end of the pusher 3321 is fixed on the core rod. The pressure head 3311 at the top of the 3310 presses against each other, and the non-clamping end of the movable claw 3324 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com