Driving mechanism of material feeding manipulator

A driving mechanism and manipulator technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unreliable insertion, high labor intensity, high labor cost, etc., and achieve stable and reliable wick insertion, high degree of automation, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

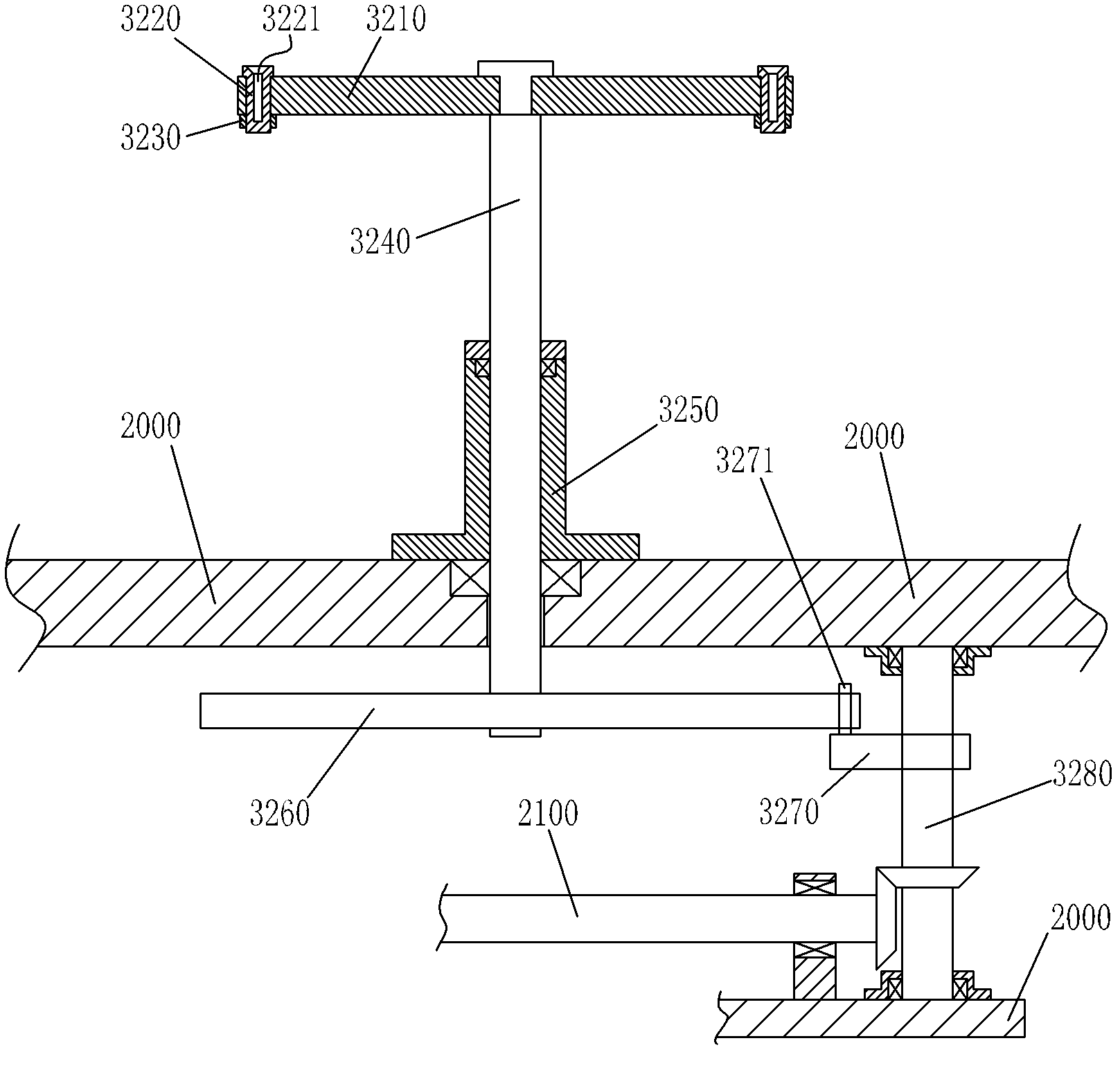

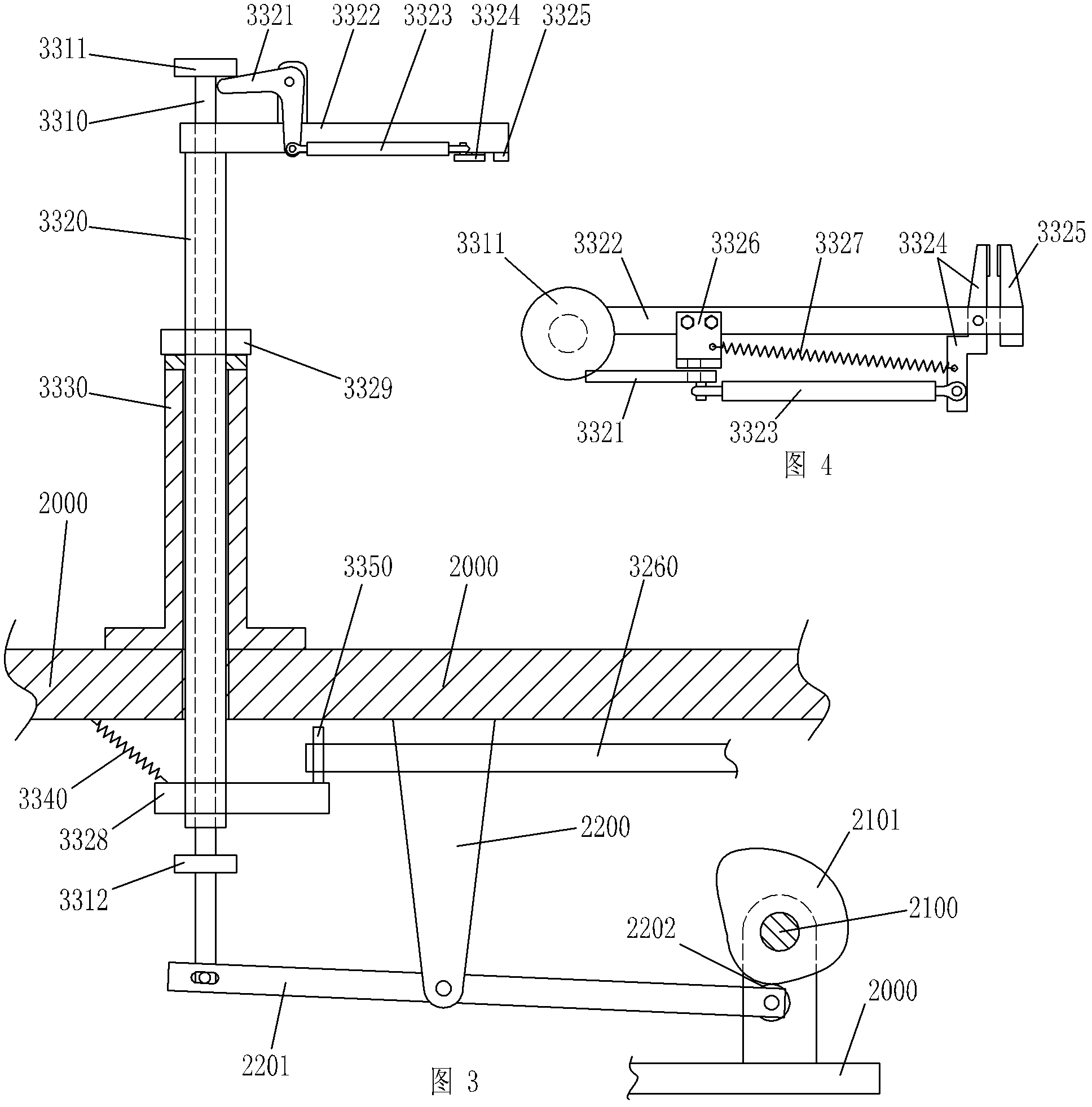

[0017] Such as image 3 , Figure 5 The driving mechanism of a feeding manipulator shown includes a rotating driving structure of the sleeve rod 3320 and a lifting and lowering driving structure of the sleeve rod 3320 and the core rod 3310 . The rotation driving structure of the sleeve rod 3320 includes a swinging member 3328 fixed on the lower end of the sleeve rod 3320. One swinging end of the swinging member 3328 is fixed with a driving rod B3350 that matches the upper tooth groove 3261 of the toggle toothed disc 3260. The swinging member The other swing end of 3328 is connected with frame 2000 through extension spring 3340 . The lifting and lowering drive structure of the sleeve rod 3320 and the core rod 3310 includes a limit block 3312 fixed on the lower end of the core rod 3310 and capable of contacting the bottom of the sleeve rod 3320 to limit the position. The lower end of the core rod 3310 is movably connected with one end of the lever 2201. The other end of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com