Assembly device for engine turbine

A technology of engines and turbines, which is applied in the field of aero-engine manufacturing and assembly, can solve the problems of inability to re-inspect assembly key elements, low assembly accuracy, and low assembly reliability, so as to ensure assembly quality, simplify assembly and balance processes, and improve Effect of Assembly Accuracy and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

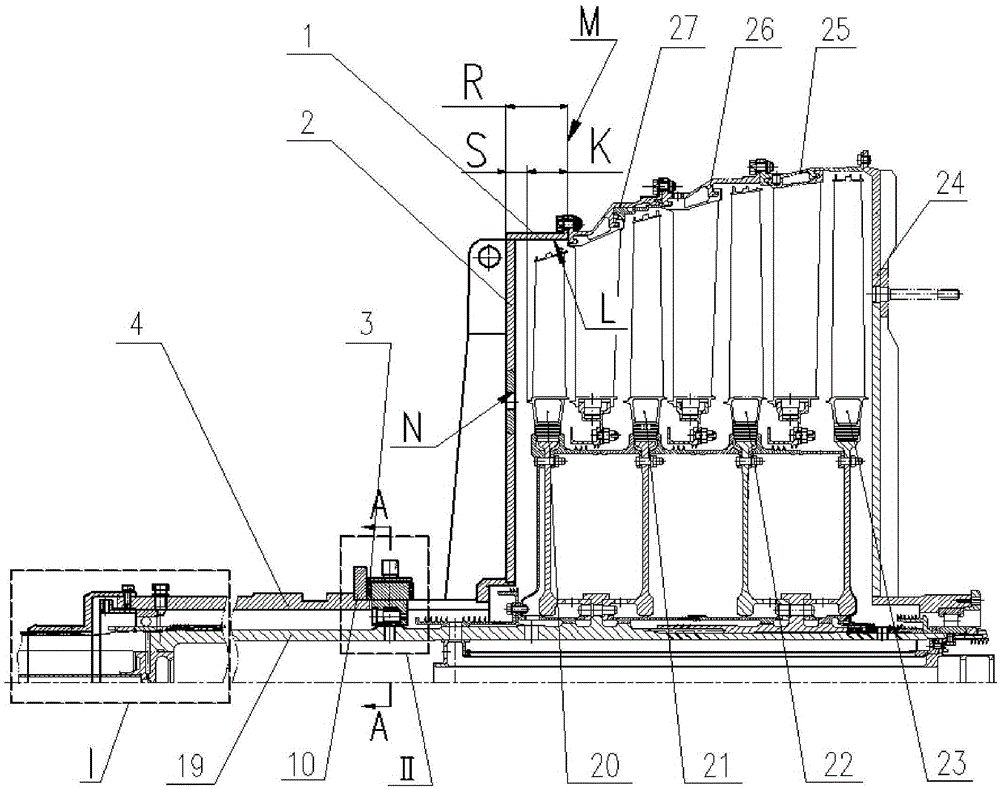

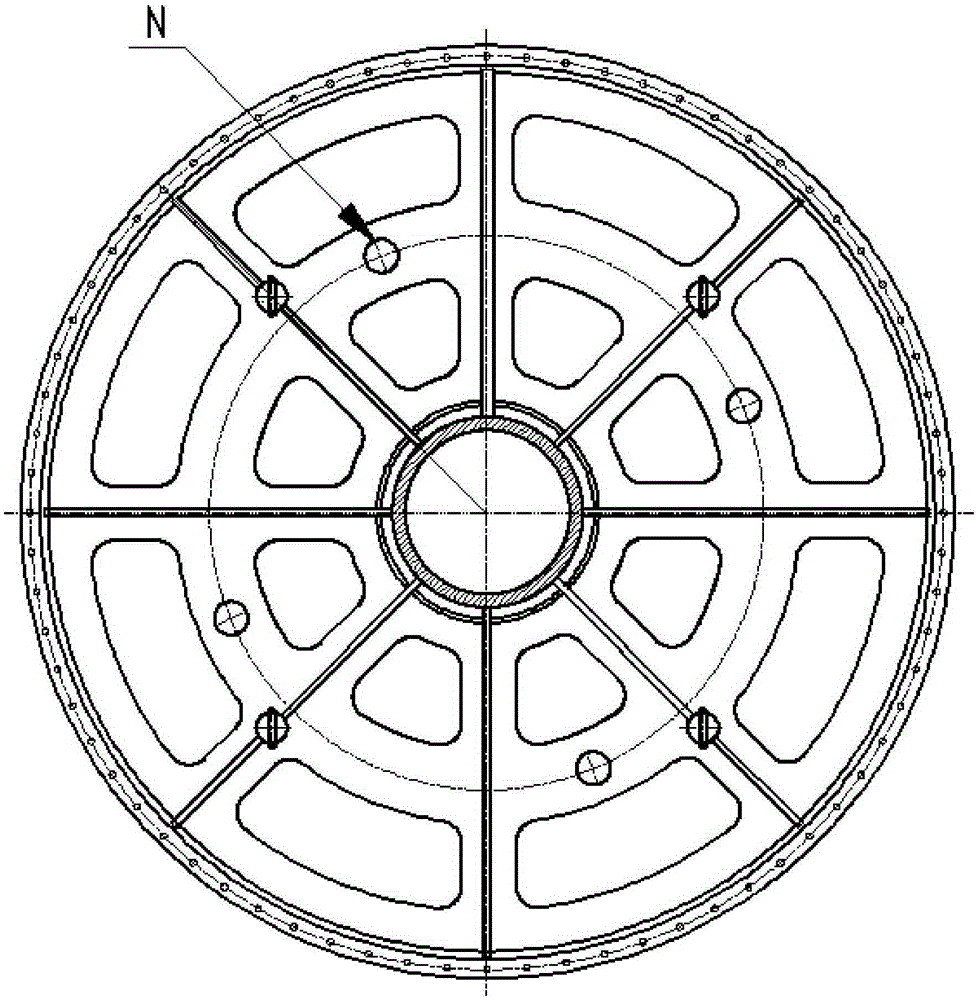

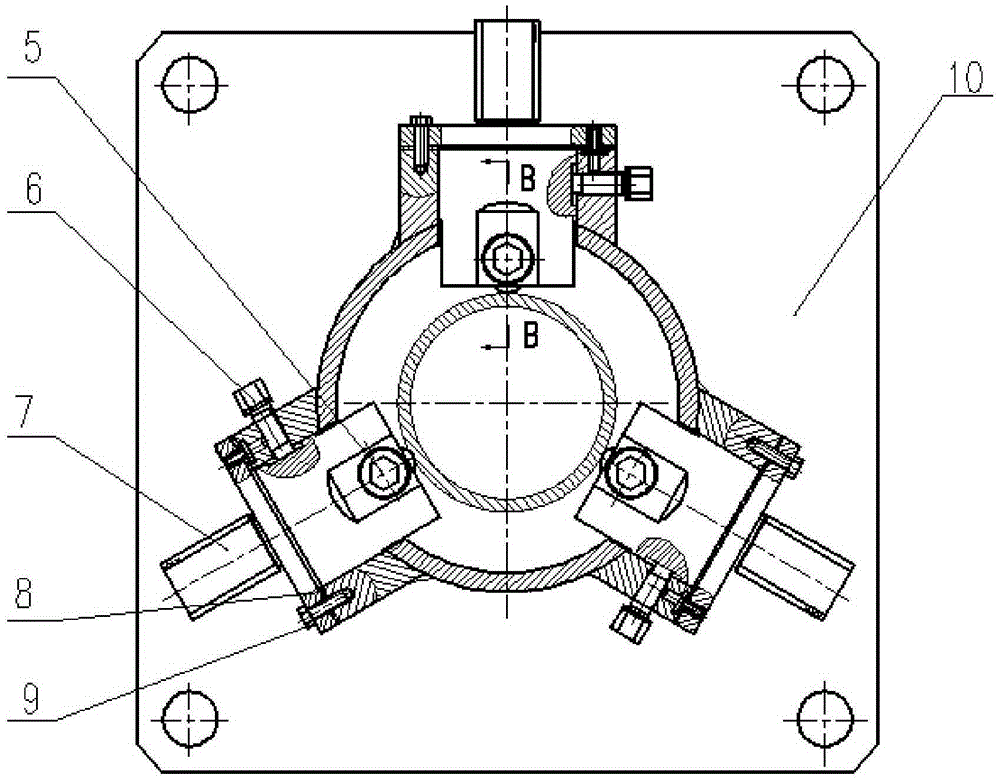

[0041] In this embodiment, the structure of the device used for engine turbine assembly is as follows Figure 1~6 As shown, it includes a cylinder 4 that is installed on the turbine rotor shaft 19 through two pairs of bearing devices and can rotate relative to the rotor shaft, a bracket plate 2 that is fixed on the cylinder near the end of the turbine rotor perpendicular to the cylinder, and is coaxial with the cylinder. The positioning ring 1 is fixed on the support plate with the inner diameter as the guide installation radial positioning reference, and the ring plate located at the outer end of the positioning ring and the butt joint end surface of the guide casing is used as the guide installation axial positioning base; the cylinder is installed Two pairs of bearing devices on the rotor shaft, the bearing device near the end of the turbine rotor is a bearing device designed with a radial fine-tuning structure, and the other bearing device is designed with an axial fine-tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com