Automatic assembling tool of impeller lining and agate of water meter

An automatic assembly and assembly station technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as non-normal use, low assembly efficiency, and failure to replace manual impeller bushings and agates. The effect of improving assembly quality and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

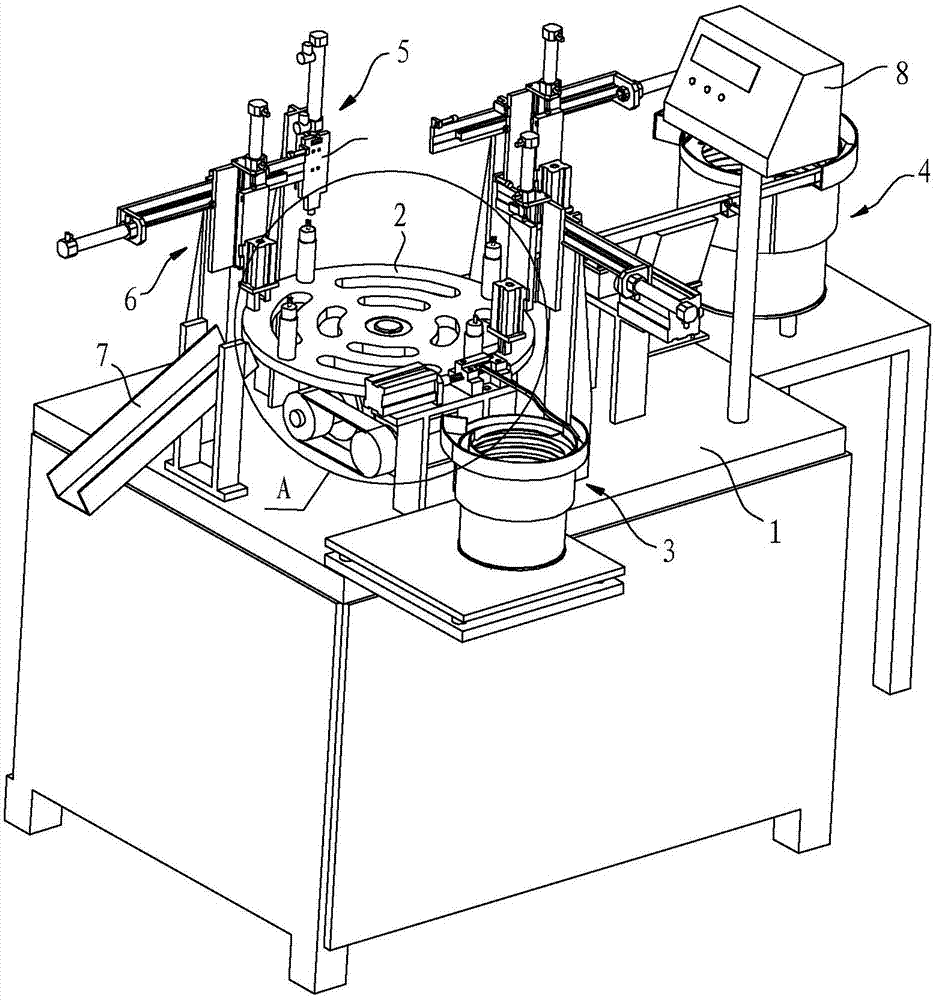

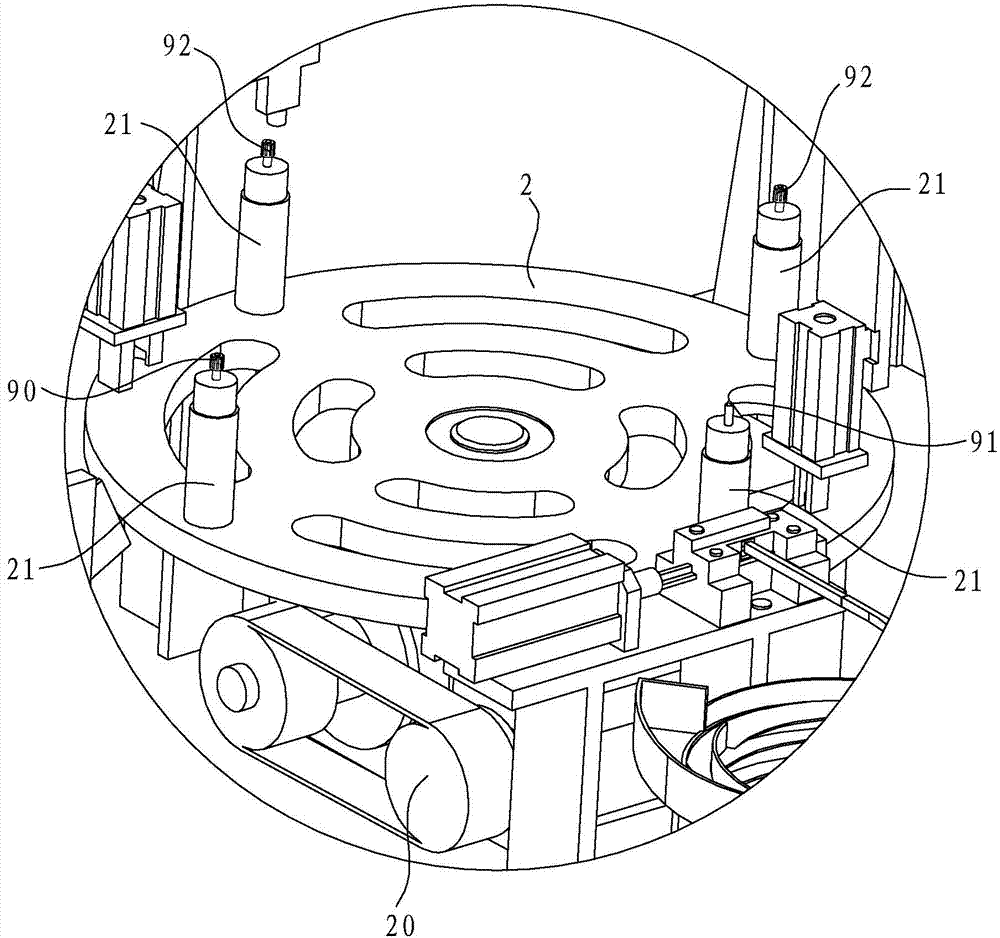

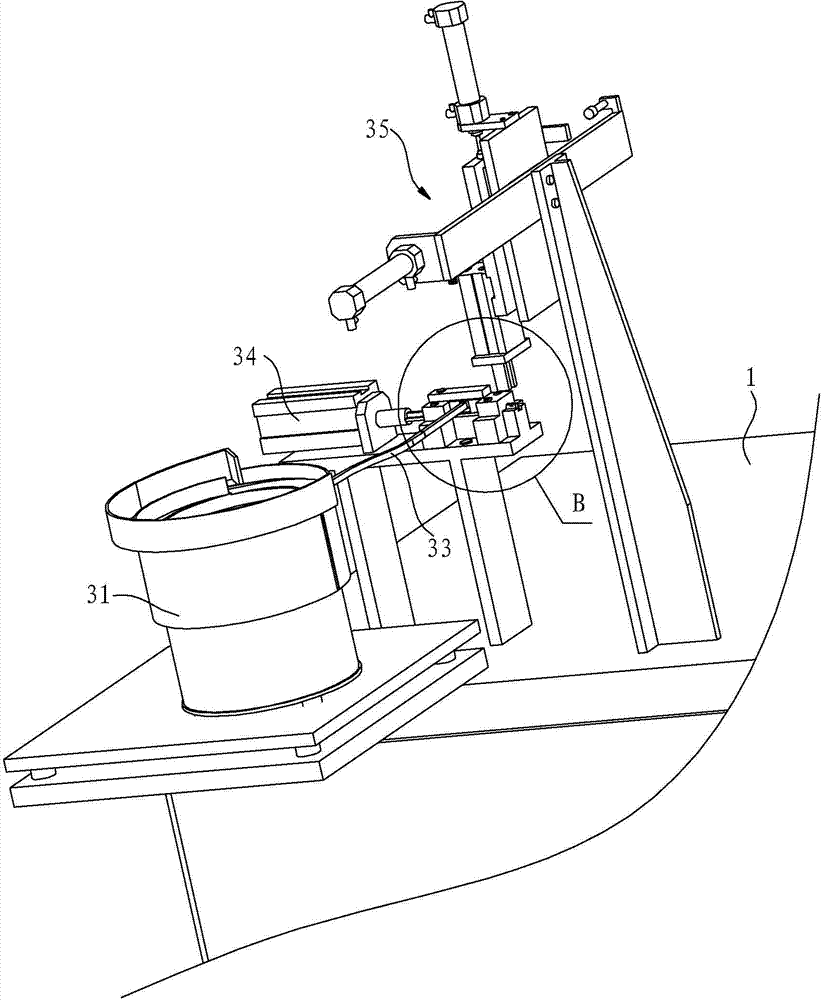

[0065] Such as figure 1 and figure 2 As shown, the water meter impeller bushing and agate automatic assembly tool in this embodiment includes a workbench 1, a rotating disk 2, an agate conveying mechanism 3, a bush conveying mechanism 4, a bush pressing mechanism 5, and a discharge and clamping mechanism 6 , output material channel 7, controller 8. The rotating disk 2 is installed on the workbench 1 and is driven by the motor 20 to rotate intermittently in the circle. There are four positioning columns 21 on the upper surface of the rotating disk 2 along the circumferential direction. The concave cavity (not shown in the figure) where the bottom of the agate is placed corresponds to the four positioning columns 21, and the agate assembly station, the bushing assembly station, the agate and the bushing assembly station are sequentially forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com