Automatic assembly machine for scissor foot

An automatic assembly machine and scissor foot technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of being unable to adapt to internal and external shear assembly, difficult to design manipulators, and difficult to install internal shears, etc., to achieve good assembly effect and executive mechanism The effect of efficient, fast and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

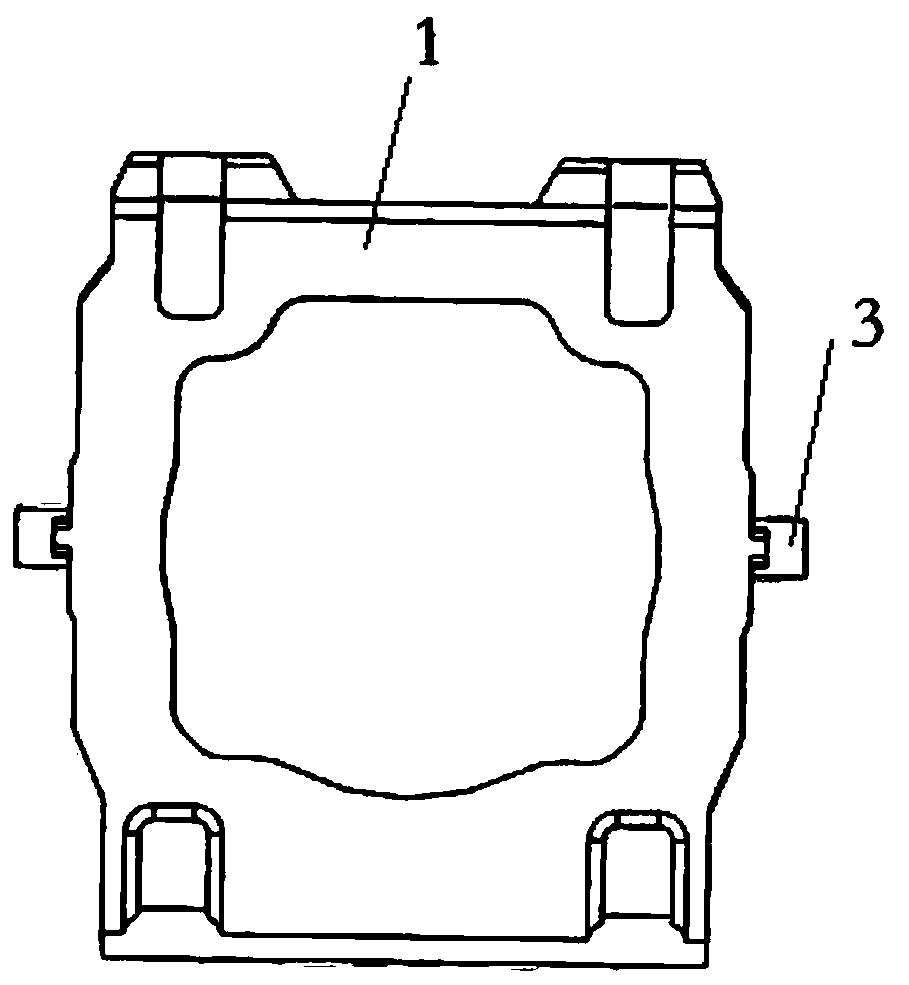

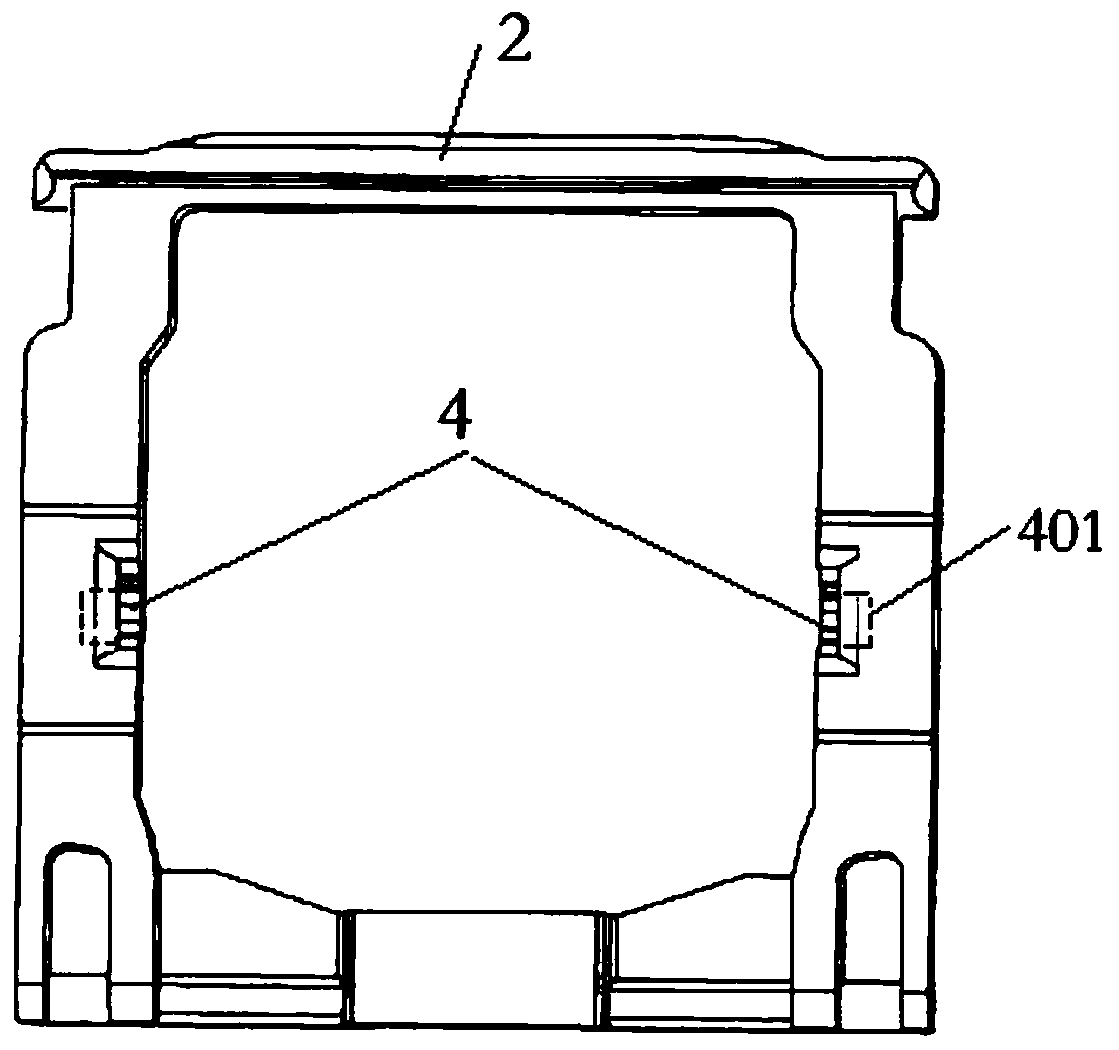

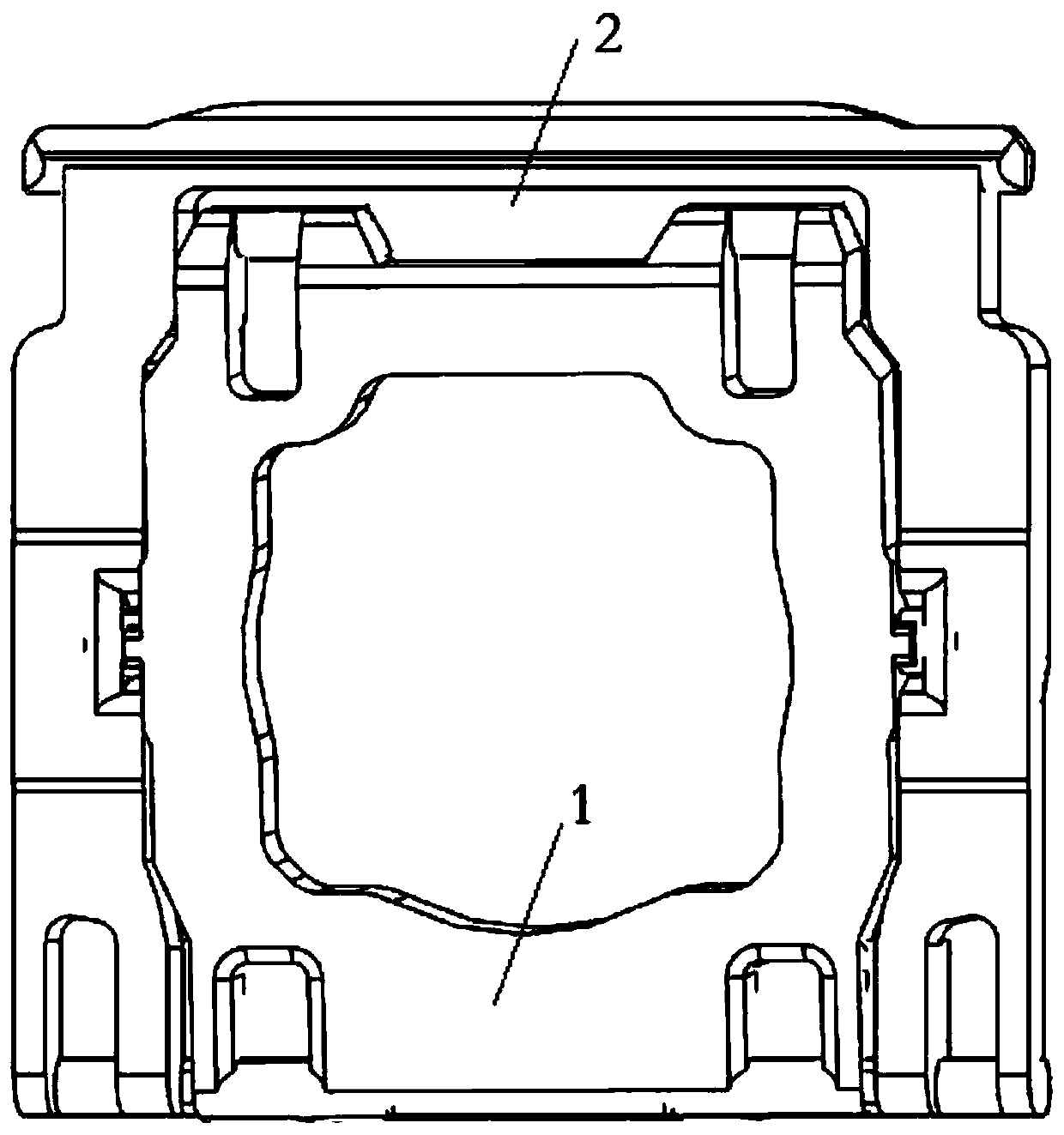

[0026] Such as Figure 5 Shown, a kind of scissor foot automatic assembly machine, it mainly comprises the lower die 200 that can move horizontally, the upper die 100 that can move horizontally and vertically, the material cutting mechanism 300 that moves vertically, the material stripping mechanism 400; Wherein, the lower mold 200 is used to place the inner shears and outer shears in advance and the upper mold 100 grabs the inner shears from the lower mold 200 to start assembly, and the cutting mechanism 300 is engaged with the lower mold 200 to make the inner shears The shears and outer shears are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com