Cable fixing clamp and cable fixing device employing cable fixing clamp

A fixing device and fixing clip technology, applied in the direction of electrical components, pipe supports, pipes/pipe joints/fittings, etc., can solve the problem that the installation performance affects the reliability and stability of the power supply system, cannot meet the strict process requirements of the cable head, and affects the sleeve. Insulation performance of pipes and cable heads, etc., to avoid deformation or damage and influence on insulation performance, improve clamping firmness, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

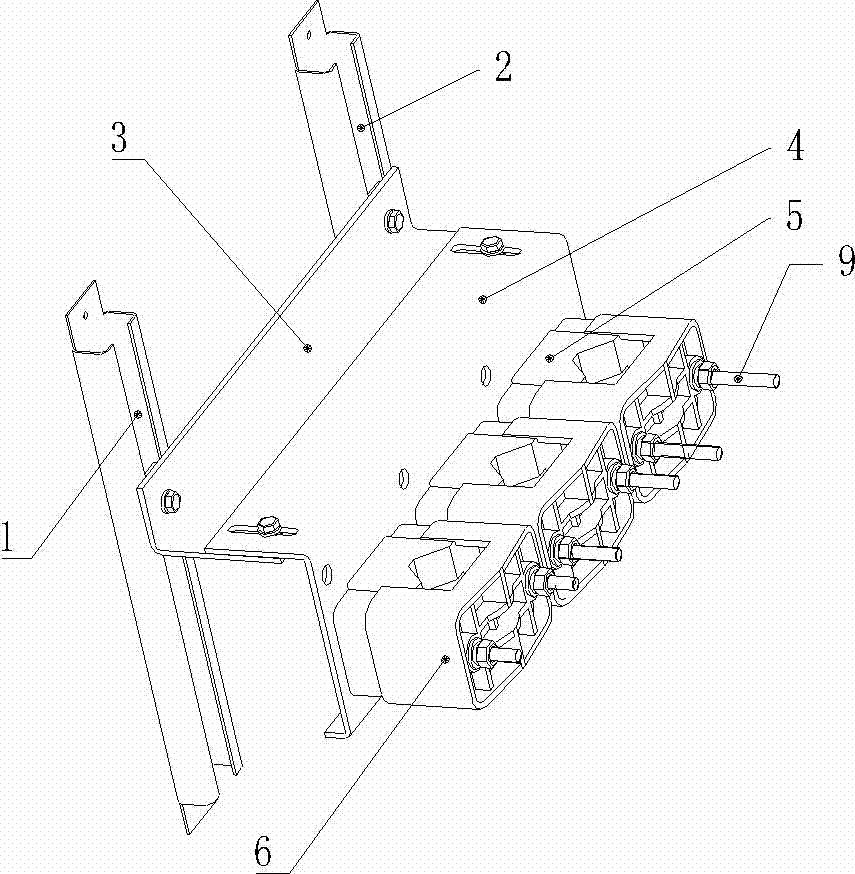

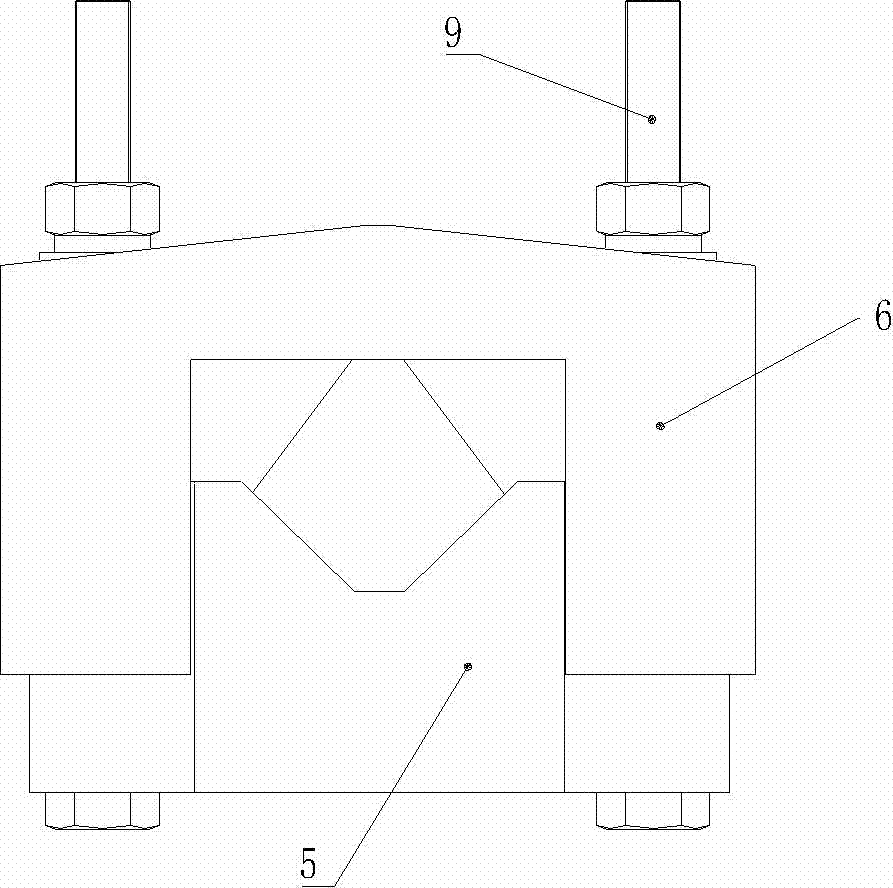

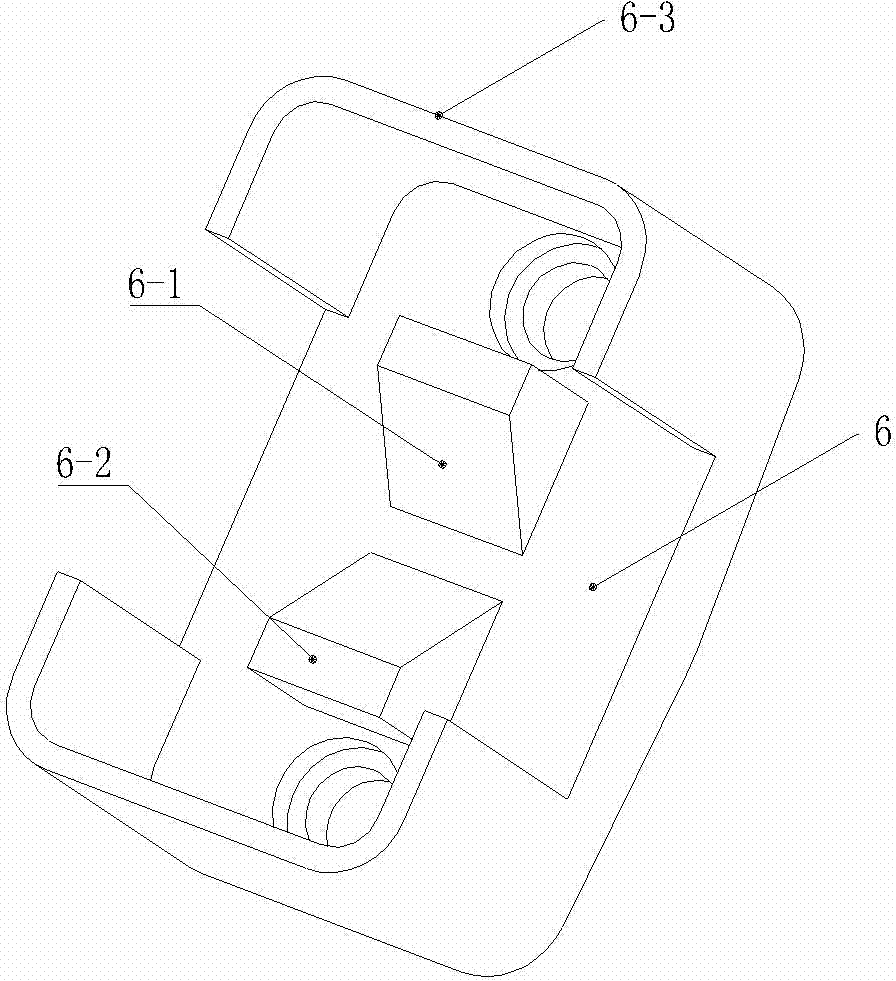

[0023] The embodiment of the cable fixing device provided by the present invention see Figure 1-Figure 5 As shown, it includes an adjustable mounting frame and three cable fixing clips fixedly installed on the adjustable mounting frame. By adjusting the adjustable mounting frame, the height, front and rear positions of the cable fixing clips can be adjusted to suit the desired Fixed position of clamped cable head.

[0024] The adjustable mounting frame includes a fixed plate 4 bent into an L shape and a connecting plate 3 bent into an L shape, and three cable fixing clips are installed in parallel on one side plate of the fixed plate 4, and the other side plate of the fixed plate Connected to one side plate of the connecting plate 3 by bolts, the board surfaces of the two side plates are stacked and fixedly connected together by bolts, wherein the threaded mounting holes provided on the fixing plate 4 are long holes, and the long holes The length direction of the cable fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com