Round sheet automatic feeding mechanism

A technology of feeding mechanism and pushing mechanism, which is applied to conveyer objects, destacking, transportation and packaging of objects, etc., can solve the problem that the whole column of circular sheets cannot be separated and transported automatically by a single sheet, and achieves a wide range of applications and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

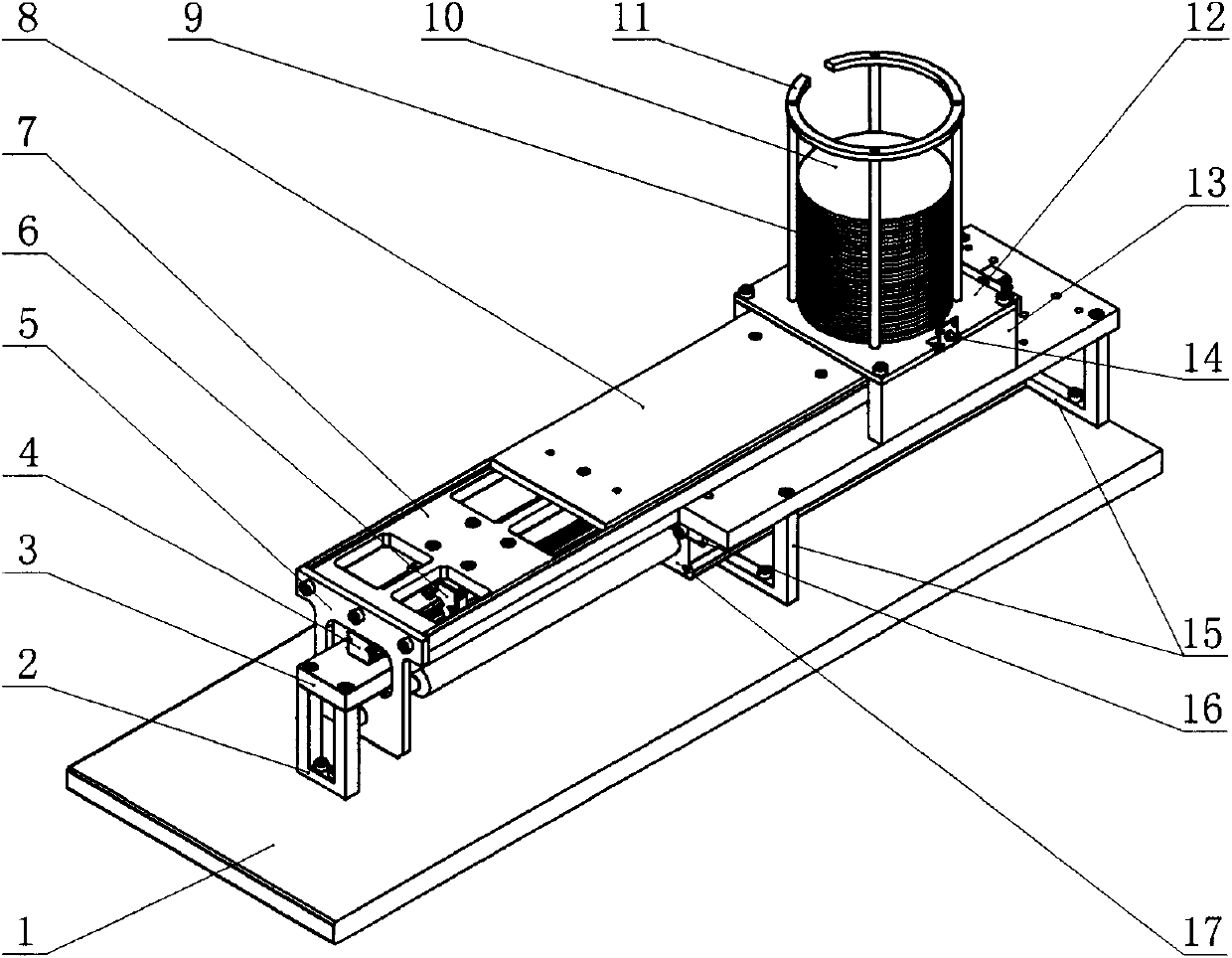

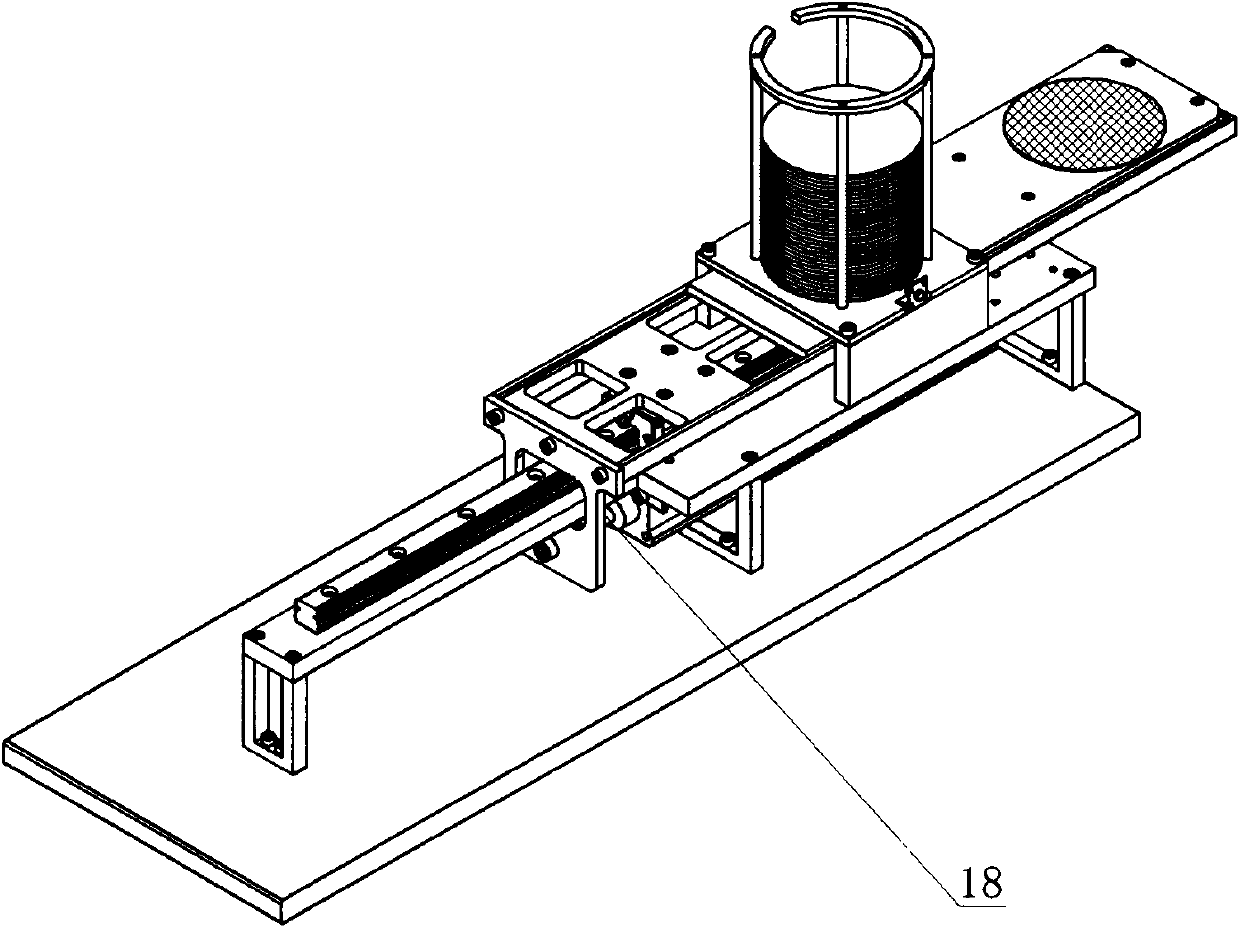

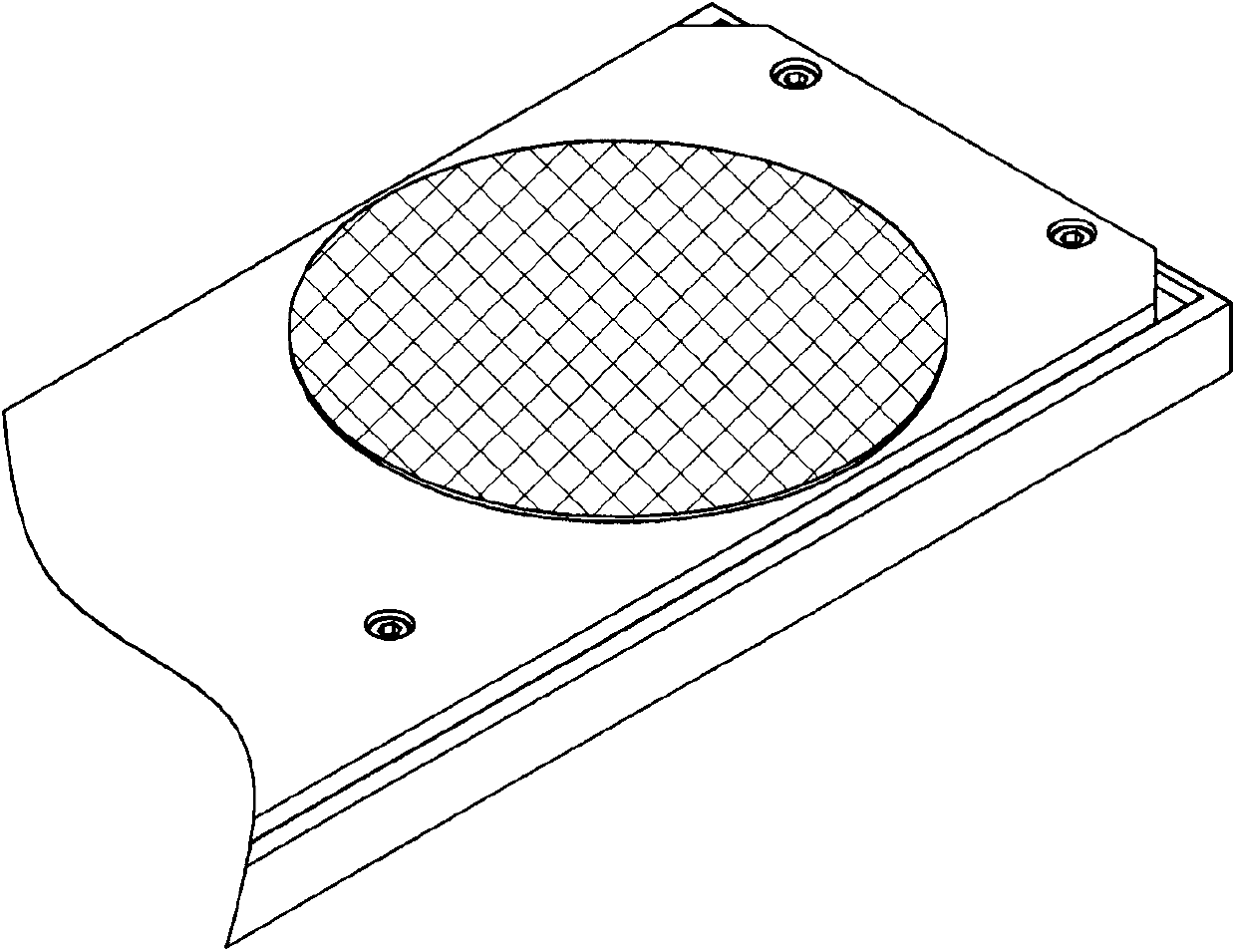

[0029] Such as figure 1 As shown, an automatic feeding mechanism for circular thin pieces: including a supporting mechanism, a pushing mechanism and a barrel mechanism.

[0030] The support mechanism is provided with a support platform 1, support frames 2, 15 and a main support plate 3: the main support plate 3 is fixedly connected to the support platform 1 through the support frames 2, 15.

[0031] The push mechanism is equipped with guide rail 4, connecting plate 5, guide rail slider 6, push plate support plate 7, circular thin piece push plate 8, cylinder foot 16, two-position cylinder 17 and floating joint 18: guide rail 4 is installed on the main support Above the plate 3; the guide rail 4 is equipped with a guide rail slider 6, and the push plate support plate 7 is connected with the guide rail slider 6 by screws; the circular thin piece push plate 8 is fixed and installed on the push plate support plate 7 by screws; the two-position cylinder 17 It is installed below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com