Production line for automatically assembling basal detonator

An automatic assembly and basic detonator technology, which is applied to weapon accessories, ammunition, offensive equipment, etc., can solve problems such as unfavorable production efficiency, achieve the effects of reduced production cost, improved production efficiency, and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

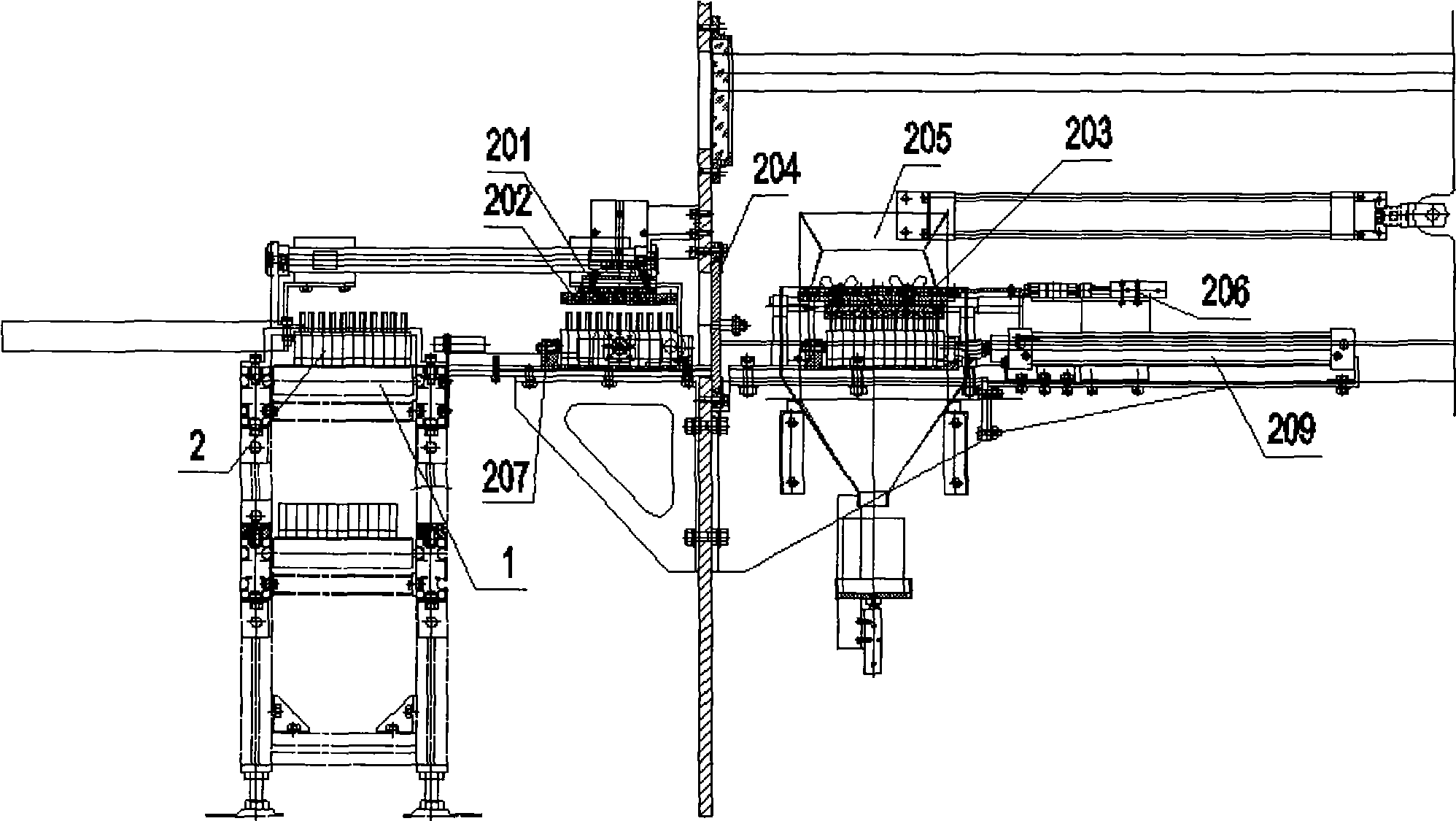

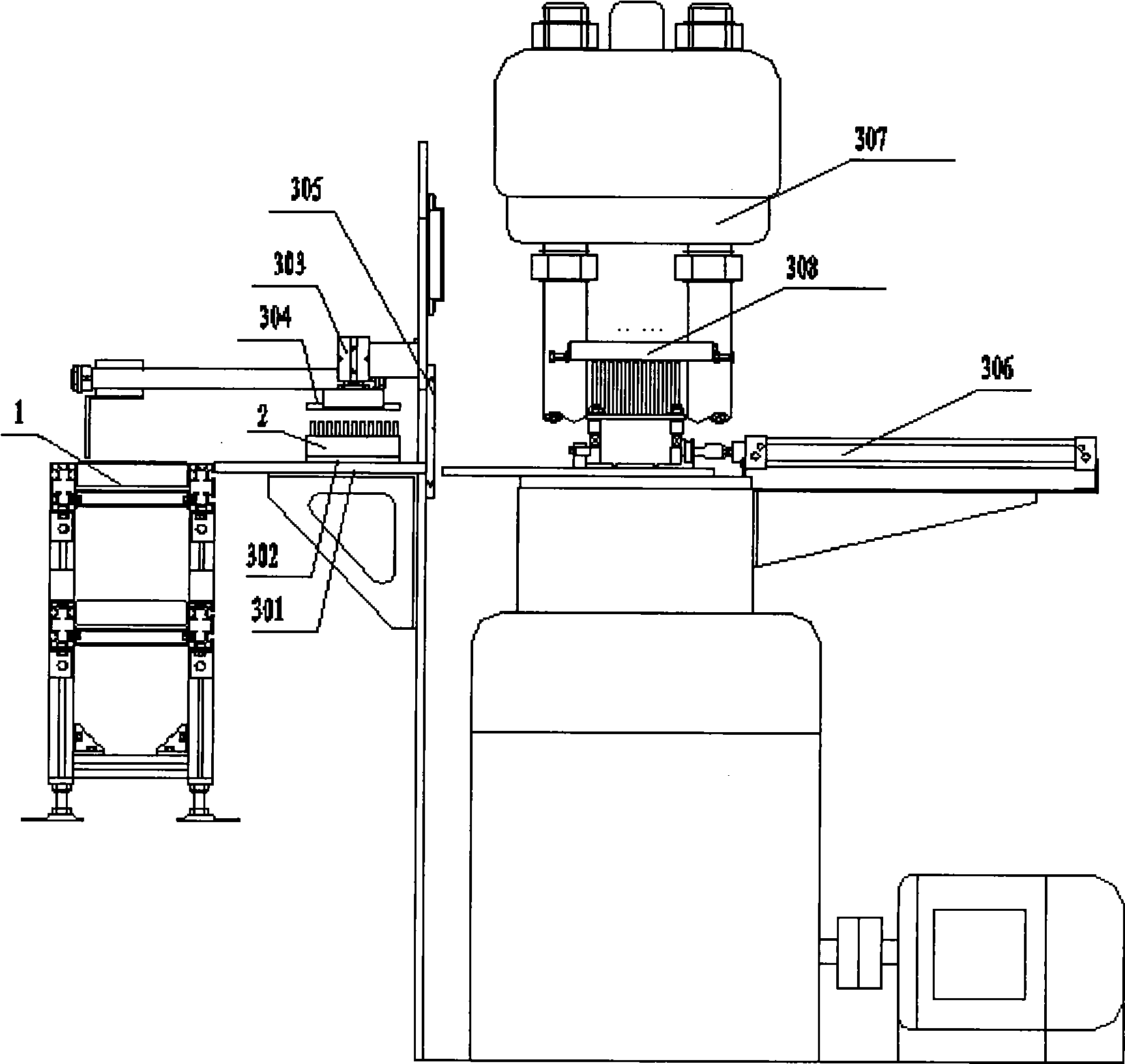

[0030] In a specific embodiment of the present invention, a basic detonator automatic assembly production line includes a basic detonator automatic assembly production line and a safety protection screen monitoring system on the production line and a configuration animation control demonstration system. The production line includes:

[0031] The metal shell automatic pipe arrangement machine, automatic medicine filling machine, automatic medicine pressing machine, automatic mold ejecting machine, automatic shaking and floating medicine machine, automatic pipe loosening machine, automatic mold splitting and mold feeding device arranged along the conveyor belt 1 and control the work of the above equipment Advanced PLC control system, whole line safety chain system;

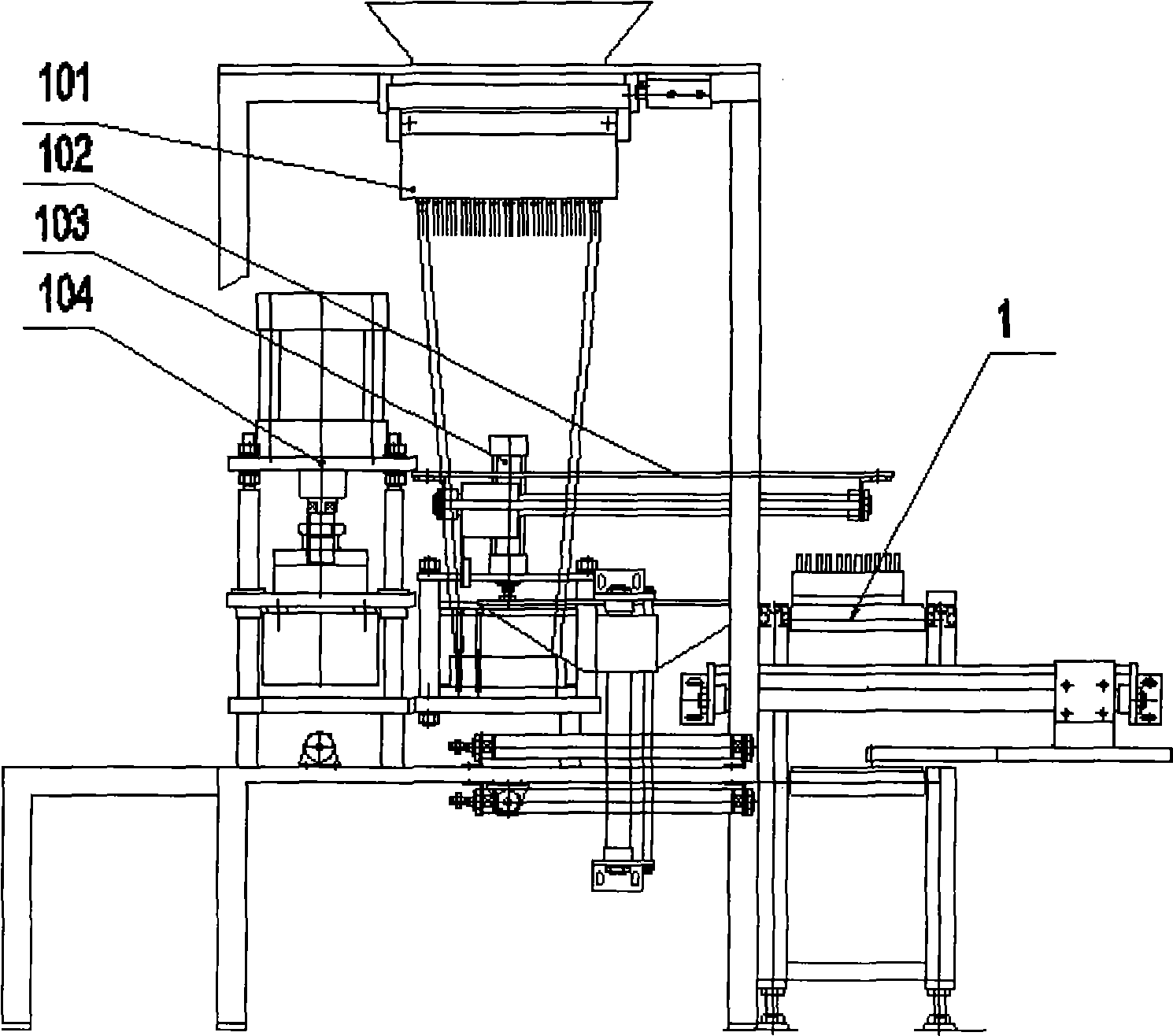

[0032] Such as figure 1 As shown, the metal shell automatic pipe arrangement machine includes a pipe arrangement drive device that drives the combined mold 2 to move at different stations, and also includes a pipe l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com