Cap assembling device

A technology for assembling equipment and covers, which is applied in mechanical equipment, metal processing equipment, metal processing, etc., can solve the problems that manual assembly cannot meet production requirements, and achieve the effect of perfecting production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

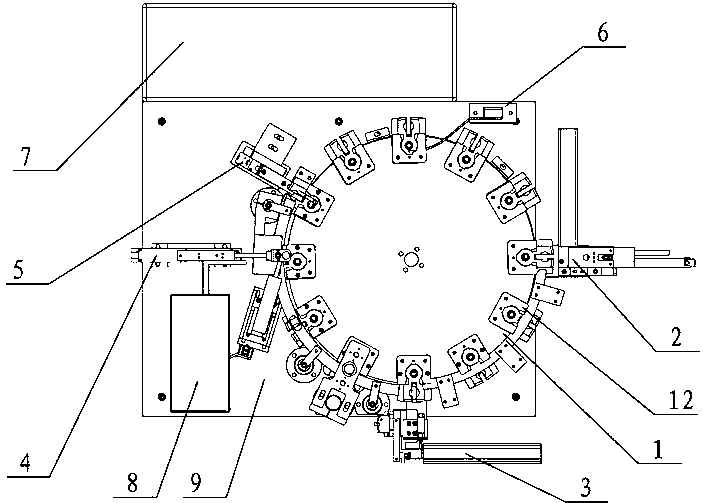

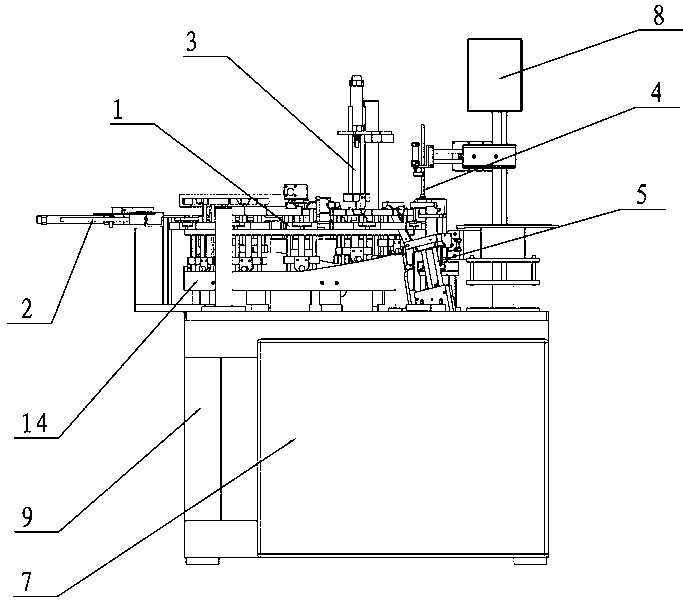

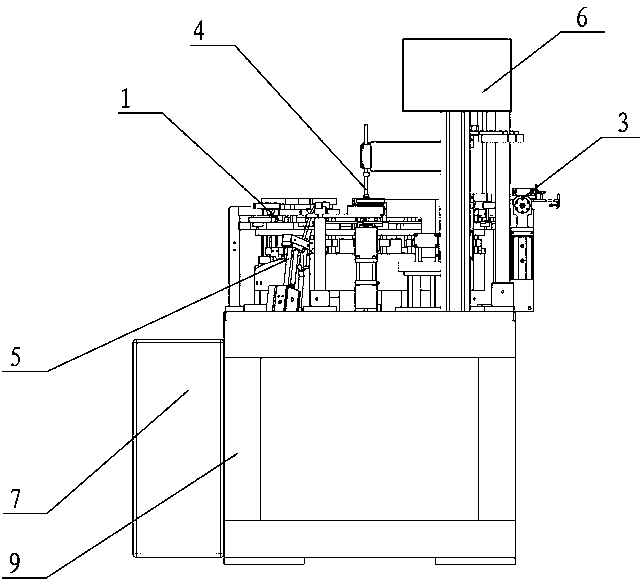

[0043] Such as figure 1 , 2 As shown in, 3, 4, and 13, a cover assembly equipment includes a rack 9 around which is fixed a power distribution box 7 for providing energy and an operating platform 8 for inputting instructions. The frame 9 is provided with a conveying device for conveying raw materials, which is divided into an upper cover conveying device 3, a lower cover conveying device 2, a cover closing device for connecting the upper and lower covers, and an output device 6 for outputting finished products.

[0044] A cover closing device 1 is arranged in the middle of the frame 9. The cover closing device 1 includes a circular index plate 11 on which 12 positioning assemblies 12 are evenly arranged along the circumference. Below the index plate 11, A position vertically aligned with the positioning assembly 12 is provided with a concave and convex station slide rail 14 surrounding it.

[0045] Such as Image 6 As shown, the station slide rail 14 is composed of two inner and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com