Manufacturing method plastic lining composite steel pipe and its manufacturing equipment

A composite steel pipe and plastic-lined technology is applied in the field of manufacturing plastic-lined composite steel pipes to achieve the effect of high production efficiency and easy production automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

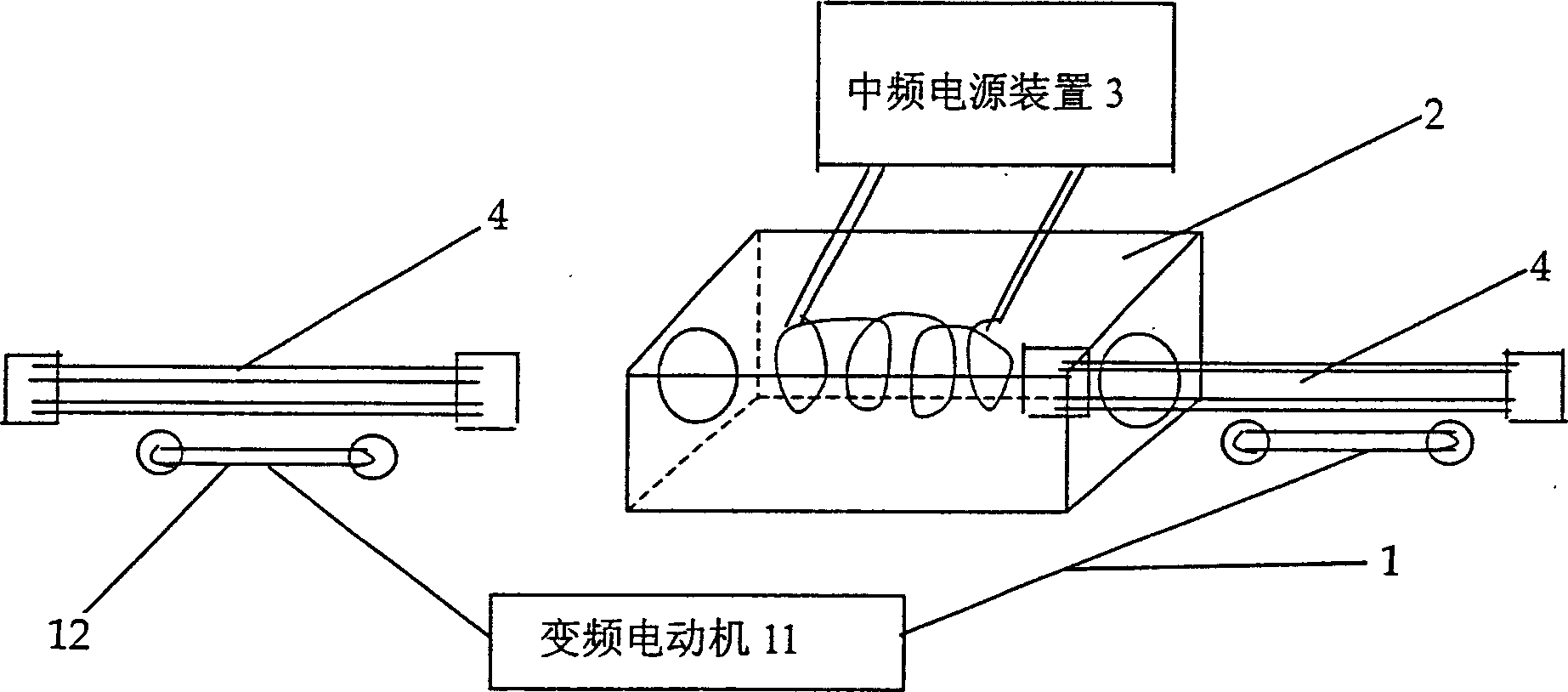

[0010] Such as figure 1 As shown: the device for manufacturing plastic-lined composite steel pipe of the present invention includes: a frequency conversion feeding device 1, an induction heater 2 and an intermediate frequency power supply device 3 connected with the induction heater 2 through a circuit. The frequency conversion feeding device 1 includes a frequency conversion motor 11 and a roller conveying line 12 controlled by the frequency conversion motor 11 . The roller conveying line 12 is divided into two sections, located at the front and back of the induction heater 2 respectively.

[0011] When compounding, the assembled steel pipes 4 are continuously placed on the roller conveying line 12 successively, and come out through the induction heater 2, and the compounding is completed. process.

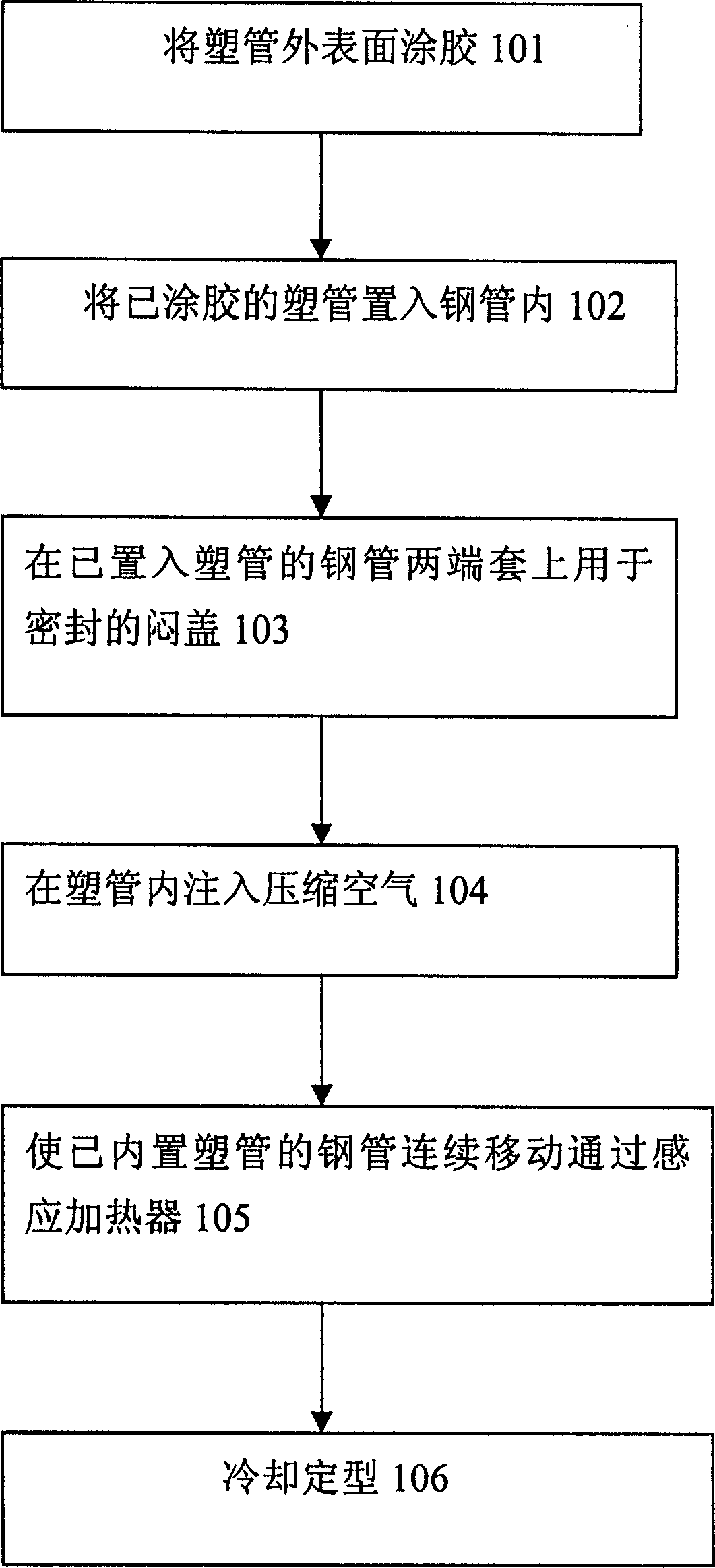

[0012] combine figure 2 Shown: the production step 100 of manufacturing plastic-lined composite steel pipe of the present invention comprises:

[0013] Step 101, coating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com