Dispensing and detection device on automatic chip mounting production line

A detection device and automatic placement technology, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. It can solve the problems of deviation in the detection effect of dispensing positions, affect process processing, access and other problems, and achieve dispensing accuracy. High, simple structure, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

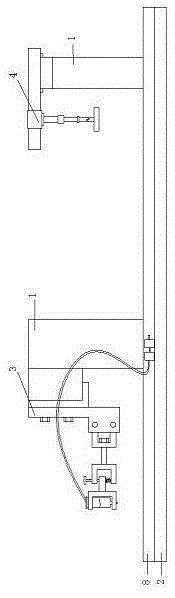

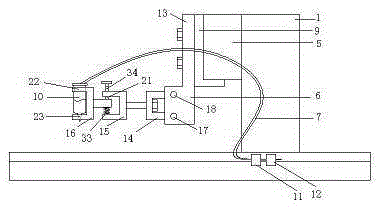

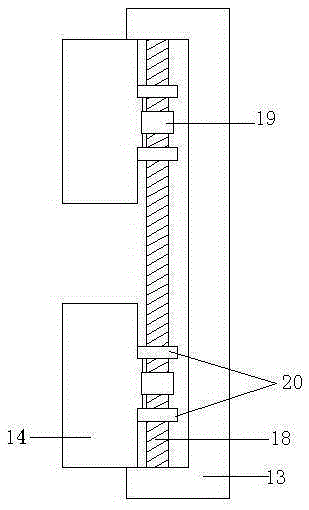

[0021] A dispensing and detection device on an automatic patch assembly line as shown in the figure includes a bracket 1 and a conveyor belt 2, and is characterized in that it includes a dispensing device 3 and a CCD detection device 4, and the dispensing device 3 includes a displacement platform 5. The fixing mechanism 6 fixed on the displacement table 5 and the dispensing mechanism 7 fixed on the fixing mechanism 6, the conveyor belt 2 is arranged below the support 1, and side plates 8 are arranged on both sides of the conveyor belt 2, and the displacement platform 5 is vertically arranged on the bracket 1, and realizes up and down displacement, the displacement table 5 includes a displacement end 9, the dispensing mechanism 7 includes a rubber storage tube 10, a solenoid valve 11 and a pressure regulating valve 12, and the fixing mechanism 6 includes a fixing plate 13. The first connecting block 14, the second connecting block 15 and the fixing block 16;

[0022] The fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com