Adhesive dispensing device

一种点胶装置、点胶器的技术,应用在对表面涂布液体的装置、涂层等方向,能够解决浪费原料、影响点胶精度、点胶量不均匀等问题,达到响应速度快、提高点胶精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

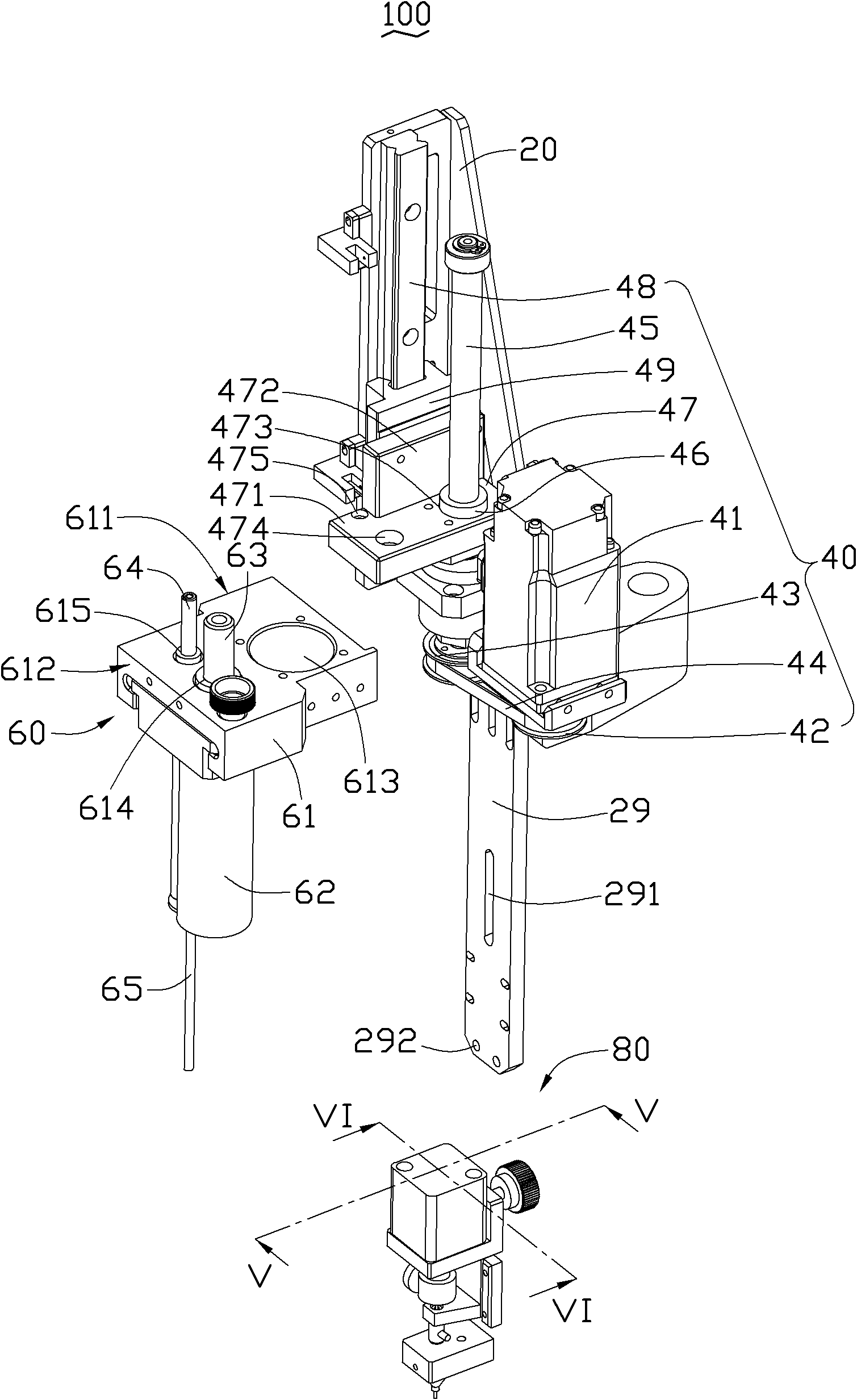

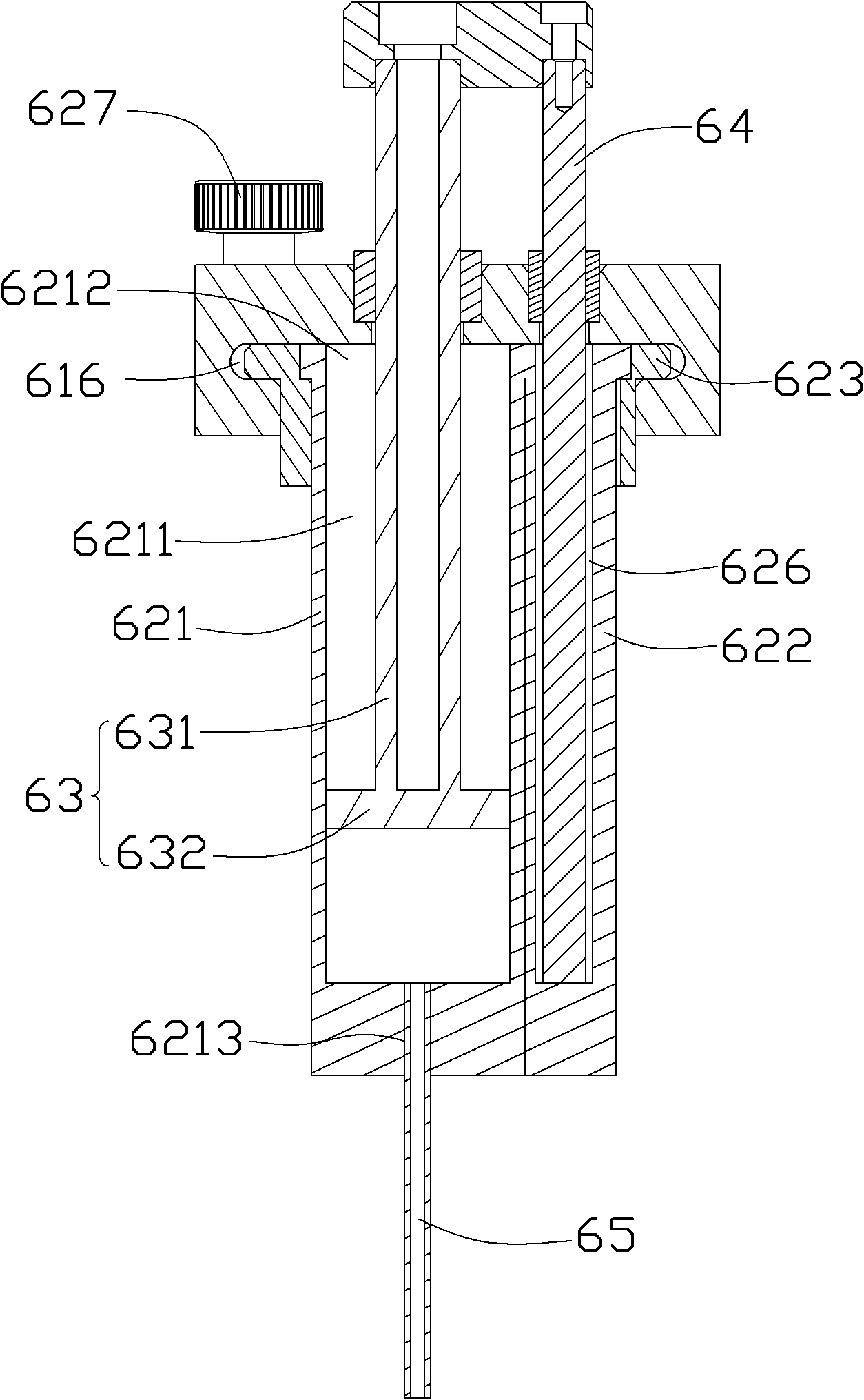

[0112] The glue dispensing device provided by the embodiment of the present invention will be further described in detail below with reference to specific implementation methods and drawings.

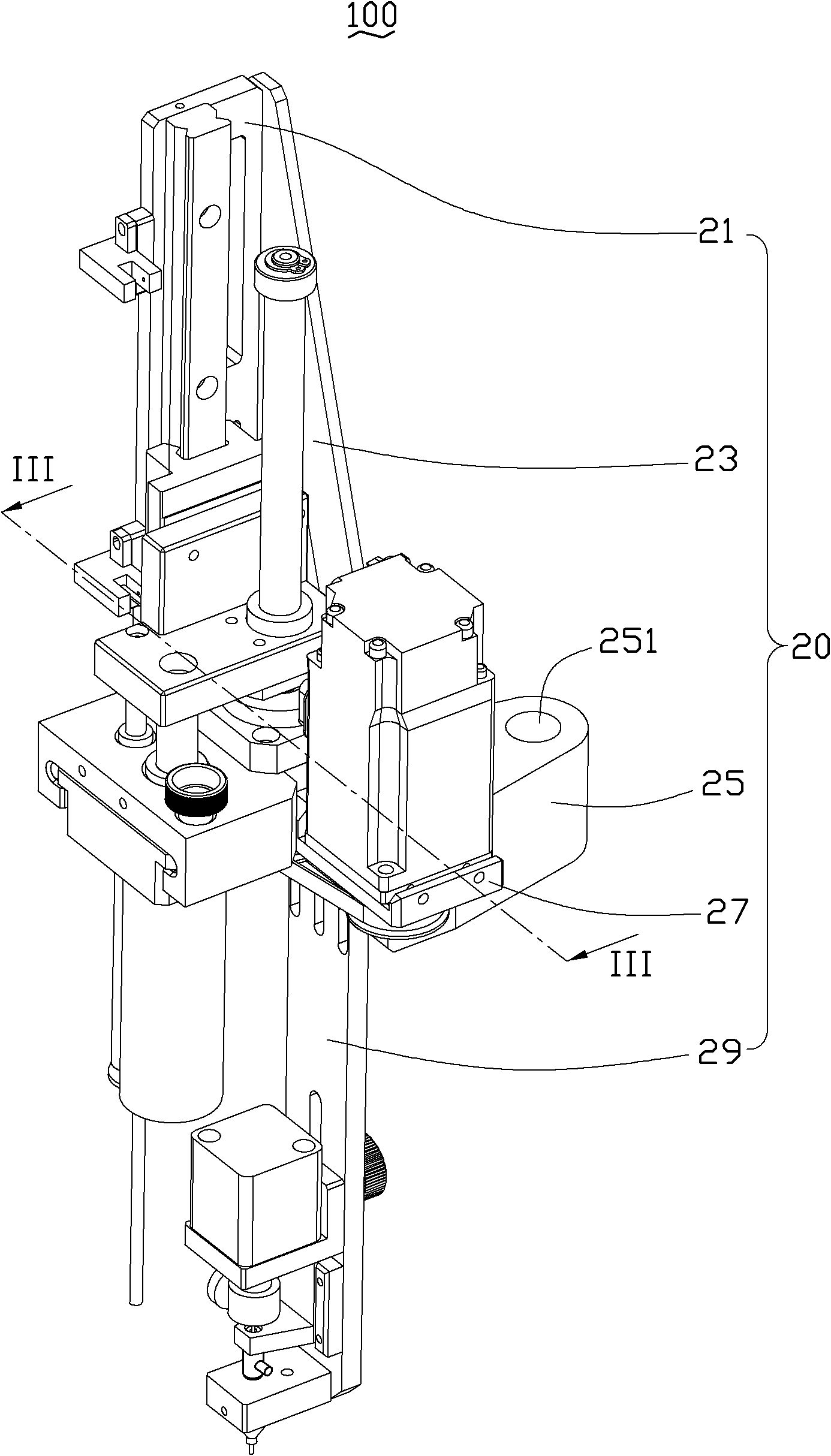

[0113] Please also see figure 1 with figure 2 , The dispensing device 100 according to Embodiment 1 of the present invention includes a bracket 20 , a driving assembly 40 , a feeding assembly 60 and a dispensing assembly 80 .

[0114] The bracket 20 includes a guide plate 21 , a reinforcing plate 23 , a connecting piece 25 , a first fixing plate 27 and a second fixing plate 29 . The guide plate 21 is substantially rectangular. The reinforcing plate 23 is generally triangular in shape and extends vertically from one side of the guiding plate 21 to the guiding plate 21 . The connecting piece 25 is block-shaped, and a connecting hole 251 is opened at one end thereof to connect the bracket 20 to the end of the robot arm. The first fixing plate 27 extends vertically from one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com