Adhesive dispensing mechanism and display screen production line

A dispensing mechanism and dispensing technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem of low dispensing efficiency, low precision of dispensing detection, and the inability to observe whether the dispensing valve is smooth or not in real time , Whether the amount of glue is up to the standard, etc., to achieve the effect of high dispensing efficiency, high dispensing precision and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

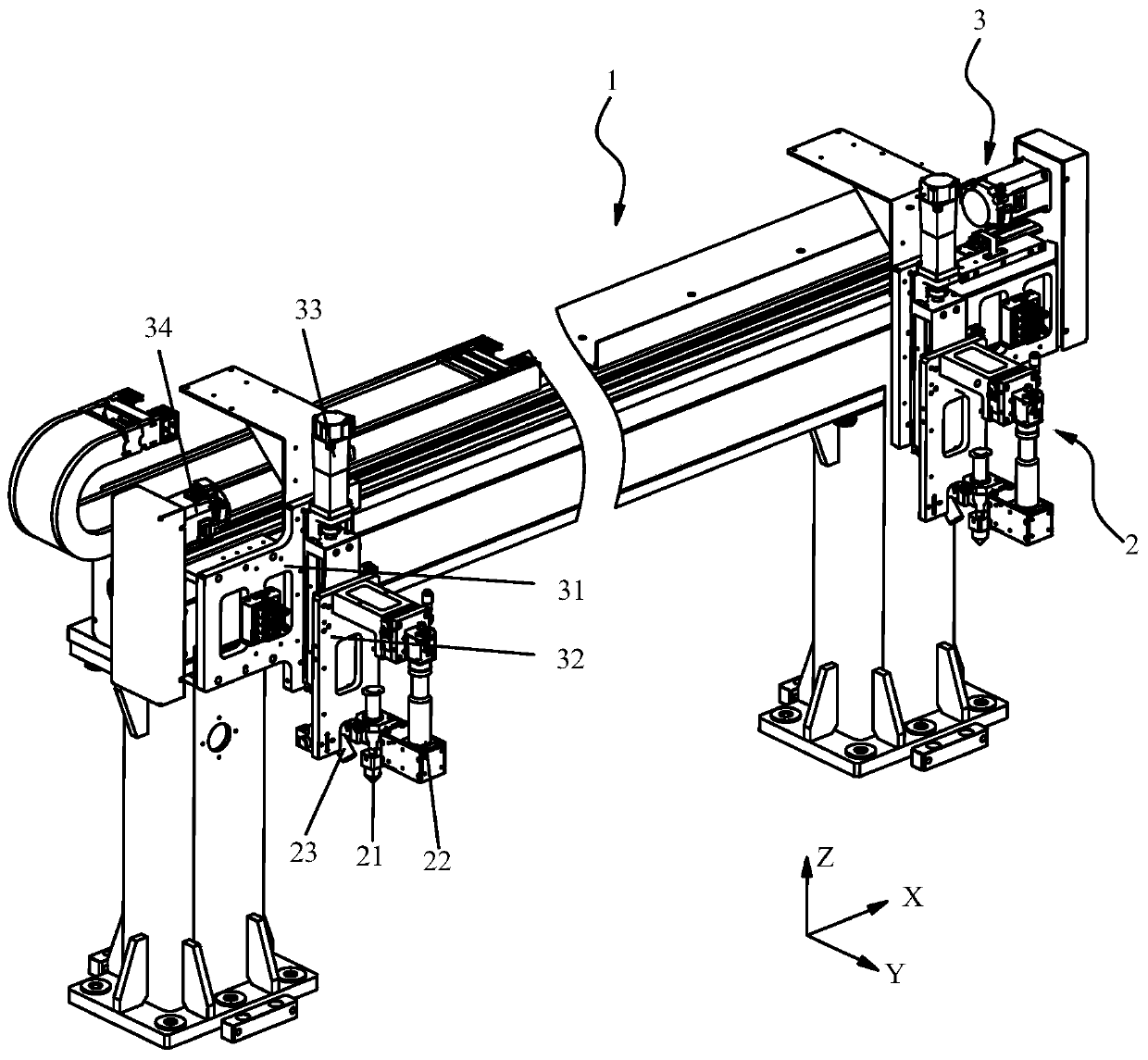

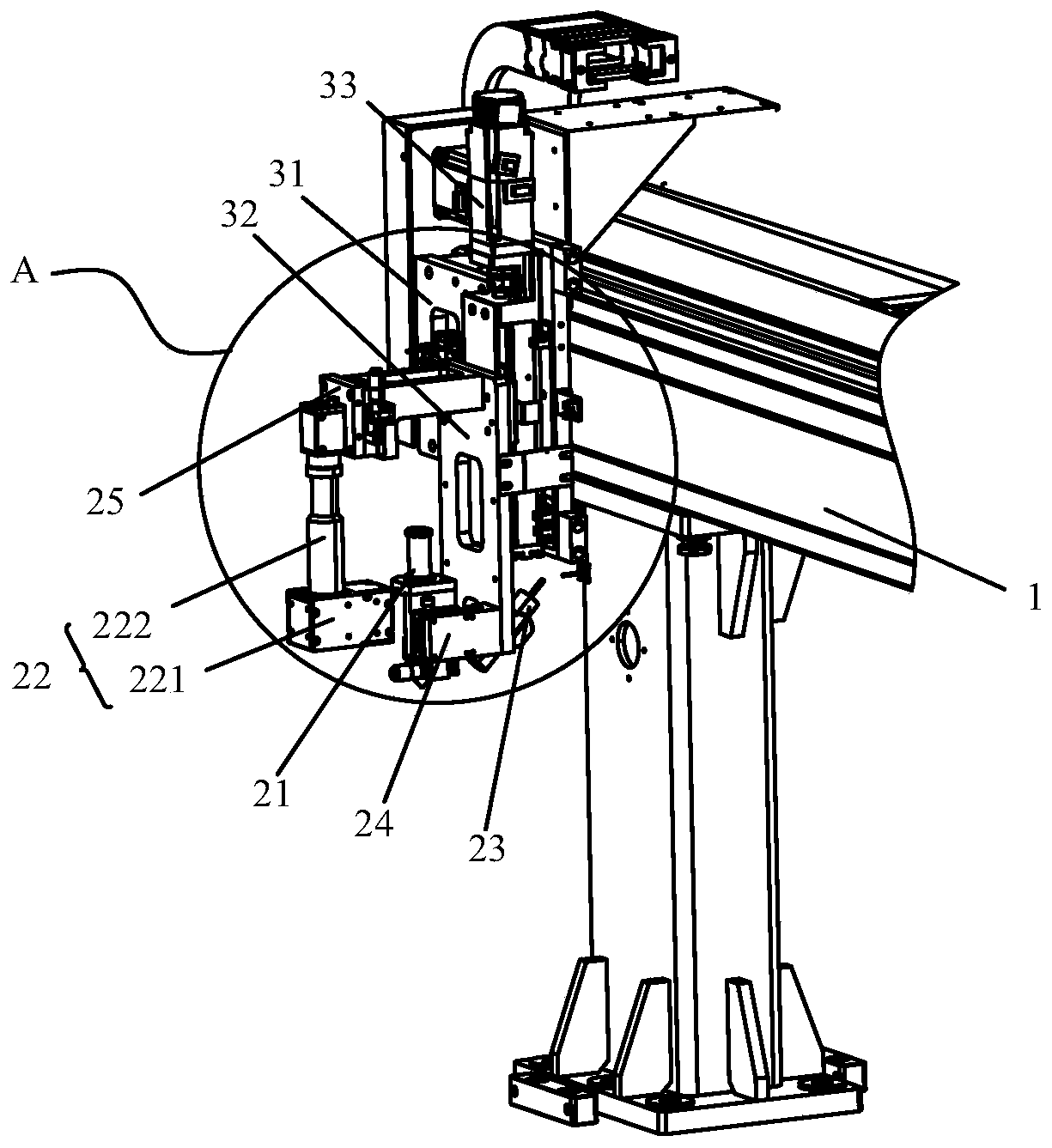

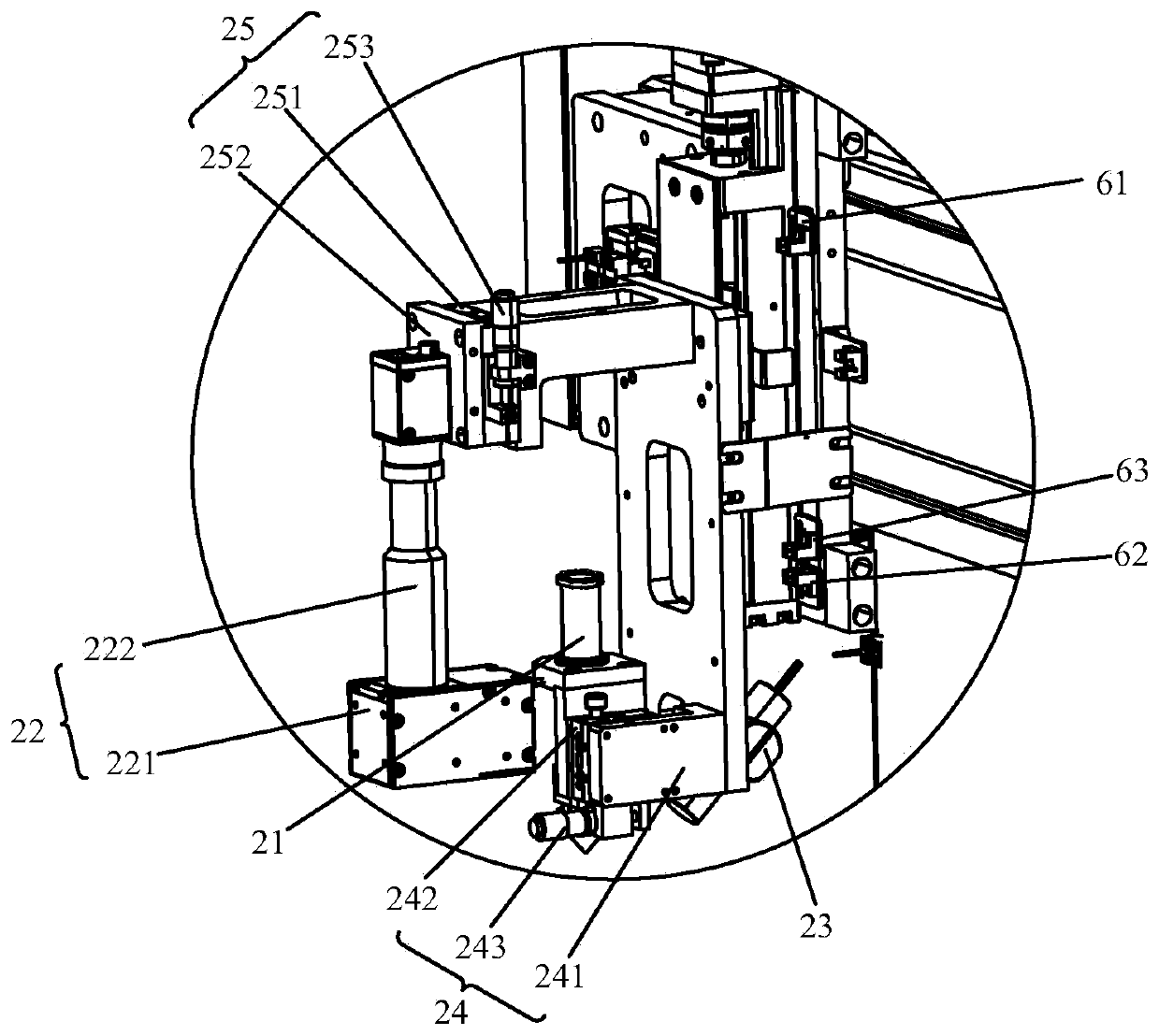

[0050] Such as figure 1As shown, the X direction in the figure is the extension direction of the gantry, the Y direction is the moving direction of the workpiece, and the Z direction is the vertical direction. The X, Y and Z directions are perpendicular to each other, and the X, Y and Z directions are only Represents the spatial direction and has no practical significance. This embodiment is especially applicable to the step of coating the conductive silver paste at the terminals of the CF layer and the TFT layer to short-circuit them. The dispensing mechanism includes a gantry 1, two sets of dispensing modules 2 and a moving module 3. The gantry 1 forms a space in the X-Z plane for the workpiece to pass through along the Y direction; two sets of dispensing modules 2 are respectively arranged in the X direction of the gantry 1. The two ends are used for dispensing the workpiece; the moving module 3 is used to drive the dispensing module 2 to move along the X and Z directions ...

Embodiment 2

[0061] This embodiment is especially suitable for coating the insulating resin glue at the terminal connecting the display panel and the COF. This embodiment differs from Embodiment 1 in that:

[0062] Such as Figure 4 As shown, the dispensing mechanism also includes a curing component 4 for curing the glue. The curing component 4 is connected to the mobile module 3. The dispensing valve 21, the CCD detection component 22 and the curing component 4 are collinear and arranged in sequence along the X direction. The curing component 4 can quickly cure the insulating resin glue that has just been placed to avoid the flow of the glue; the dispensing valve 21, the CCD detection component 22 and the curing component 4 are arranged on the same line along the X direction, so as to ensure that the moving module 2 is aligned along the X direction. In the process of direction movement, it can not only complete dispensing, inspection of dispensing quality and colloid curing at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com