Multifunctional testing table for property and application of liquid and gas jet pump

A liquid-gas jet pump, multi-functional technology, applied in pump testing, liquid variable-capacity machinery, machines/engines, etc., can solve the problems of waste of workload, single function, no convenient and reliable drug delivery method, etc., and achieve a simple and reliable structure. , the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

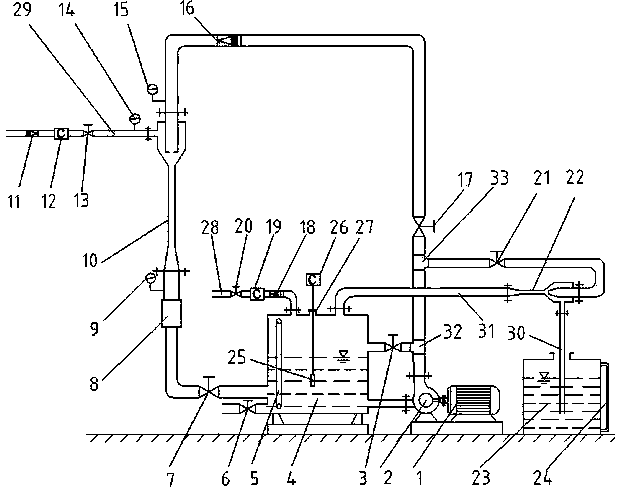

[0023] like figure 1 As shown in Fig. 1, a multifunctional test bench for the performance and application of liquid-air jet pump is composed of a test system and a dosing system.

[0024] The test system includes the main water tank 4, the centrifugal pump unit, the liquid-air jet pump 10, the test parameter measuring instrument, the connecting pipeline and the gate valve; and the cross-sectional area of the main water tank is 1.8m 2 , the centrifugal pump unit includes a motor 1 and a centrifugal pump 2; the suction end of the centrifugal pump 2 is connected to the main water tank 4, the outlet pipe of the centrifugal pump is arranged vertically upwards, connected to a liquid flow meter 16 installed horizontally, and the pipeline that turns vertically downward is provided with a second Three presses 15 are connected to the liquid-air jet pump 10 to be tested; the outlet pipeline of the liquid-air jet pump 10 is connected to the main water tank 4 after connecting the first ...

Embodiment 2

[0029] Same as Example 1, the difference is that the test is the waste gas absorption simulation test process: based on the performance test of the liquid-air jet pump, the gas sucked by the liquid-air jet pump 10 is industrial waste gas or artificially set simulated waste gas, which is measured by the gas concentration meter 12 For gas inhalation concentration, the gas concentration meter 19 measures the gas-liquid concentration after gas-liquid mixing and separation, and after the gas is discharged. Similarly, the gas flow meters 11 and 18 measure the inhaled gas flow and the exhaust gas flow respectively. The liquid phase concentration is obtained by measuring the liquid phase concentration sensor 25, and the liquid phase concentration meter 26 reflects the concentration, and monitors whether the water body is close to saturation, thereby judging whether it is necessary to open the shunt gate valve 21 for drug administration. Part of the water pressurized by the centrifugal ...

Embodiment 3

[0031] With embodiment 1, the difference is that the test is an oxygenation and aeration test process: based on the performance test process of the liquid-air jet pump, the water level in the main water tank 4 is calculated by the water level of the liquid level gauge 5 before the test. The dissolved oxygen in the water body in the main water tank 4 drops to nearly zero, and the centrifugal pump 2 is turned on to provide working water for the liquid-air jet pump 10. The liquid-air jet pump 10 sucks air, and the air mixes into the main water tank 4 for oxygenation. The data of the liquid phase concentration meter 26 is recorded at intervals, reflecting the change of the oxygen concentration in the main water tank 4 until the oxygen in the water reaches saturation, and the oxygenation and aeration test process is completed. Wherein the threading sealing cover 27 not only allows the concentration meter cable to pass through, but also the thermometer and other signal cables can pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com