Robot travelling along overhead high voltage transmission line

A technology for high-voltage transmission lines and robots, applied in the field of robots, can solve problems such as affecting work efficiency, not having to cross obstacles, and being unsafe, and achieve the effects of reducing labor intensity, high inspection accuracy, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

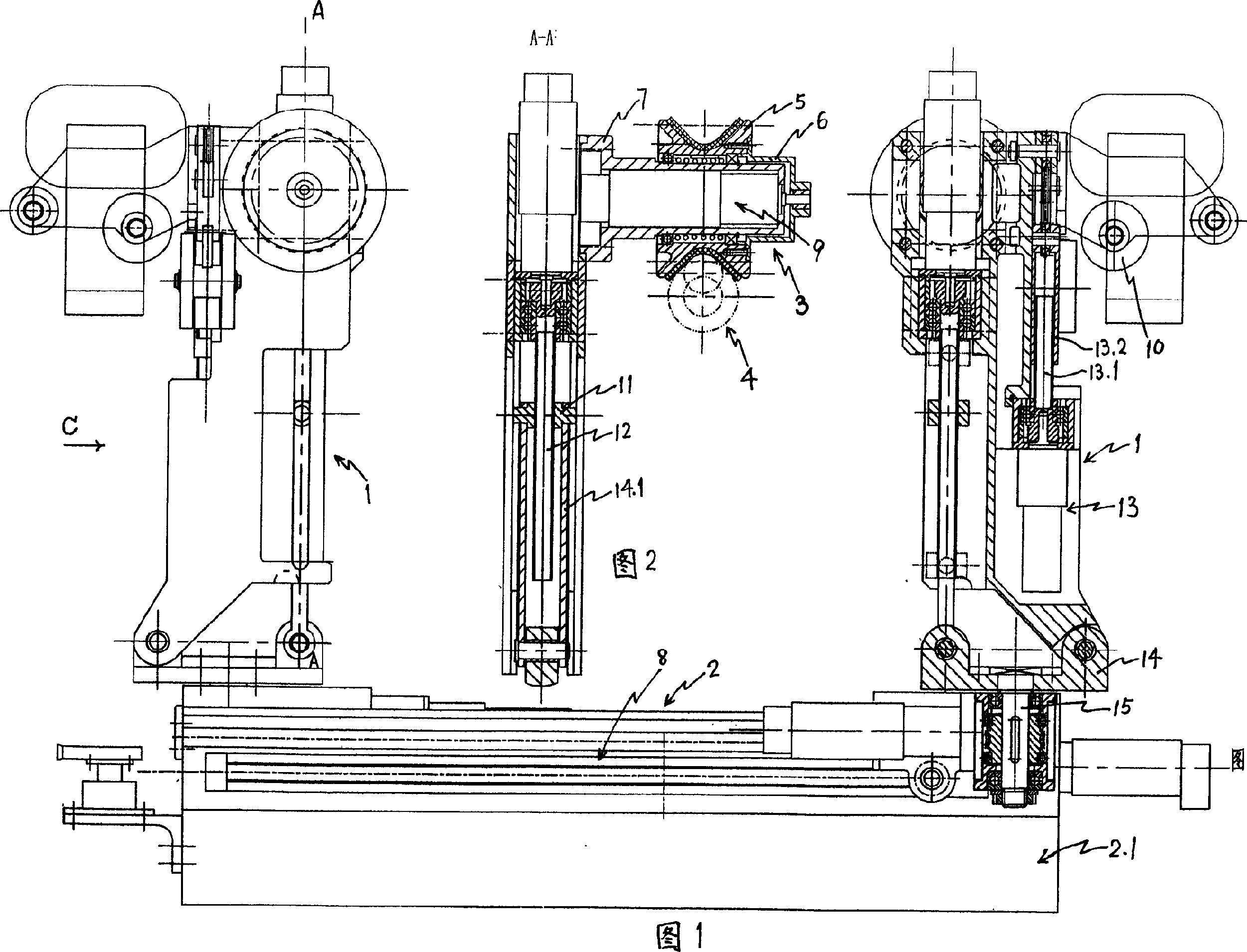

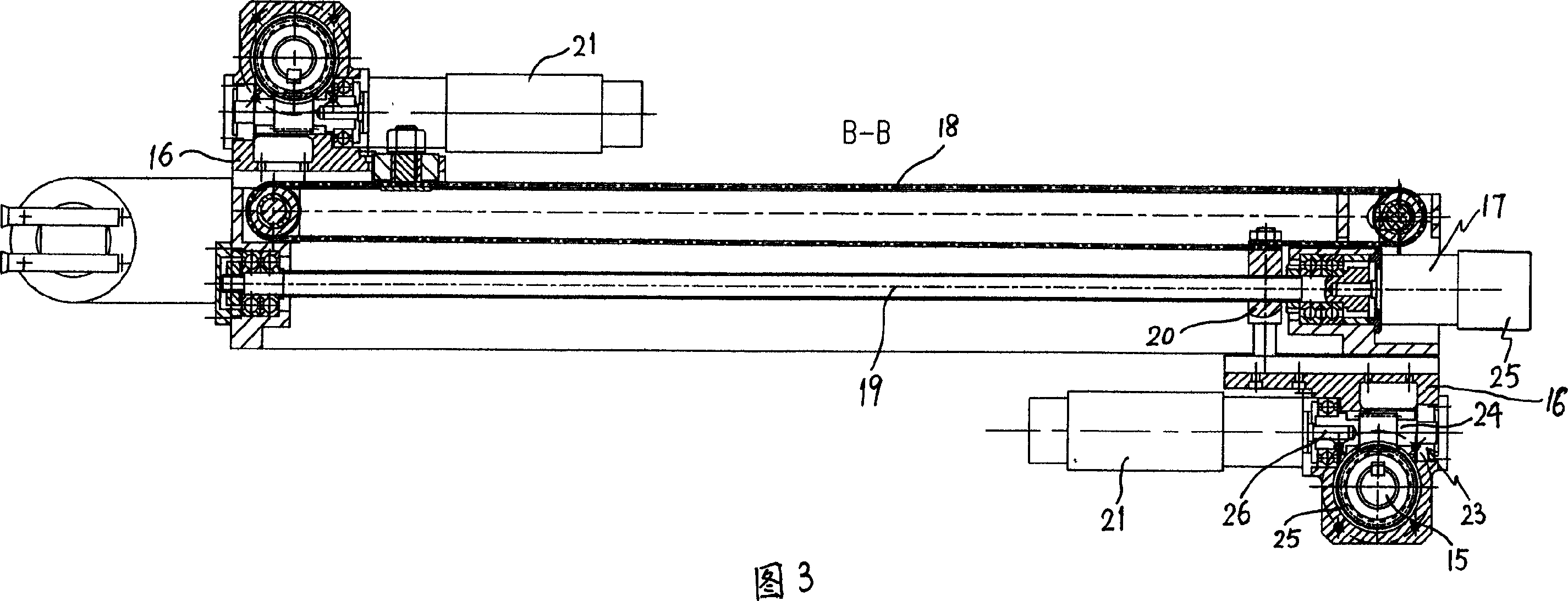

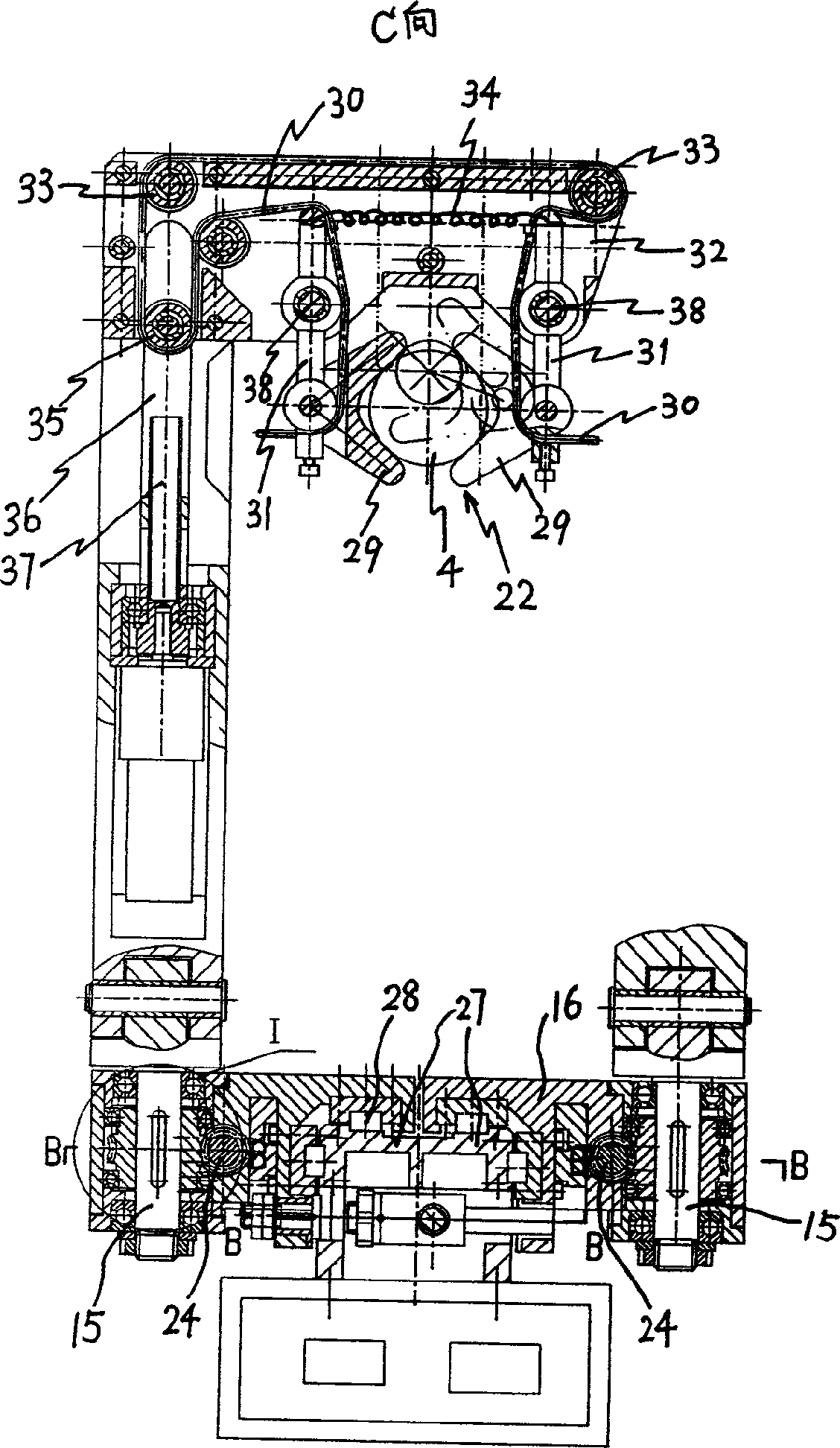

[0016] Referring to Fig. 1-Fig. 6, what the present invention describes is a kind of robot that is used for traveling along the overhead high-voltage transmission line, and it comprises a pair of forearm 1 manipulator mechanism that moves along the transmission line, the lower end of two forearm 1 manipulators is jointly Connected to a transmission mechanism 8 of the big arm 2 that can change the relative distance between the two small arms 1, each small arm 1 has 4 degrees of freedom, and above the small arm 1 is the end effector 3, which has a hanging The driving wheel 5 on the power line 4 and its driving mechanism 9 , a driven wheel 10 and a clamping mechanism 22 capable of gripping the power line 4 .

[0017] A further technical solution may be: the driving mechanism 9 that makes the driving wheel 5 of the forearm 1 rotate around the horizontal axis is placed in the unloading shaft 7, the output shaft of the driving mechanism 9 is connected with the driving disc 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com