Graphene radiating apparatus and preparation method therefor

A technology of heat dissipation device and graphene, applied in graphene, lamination device, chemical instrument and method, etc., can solve the problems of inability to greatly reduce the thermal resistance between infrared particle interfaces, endangering environmental protection, safety, and unsatisfactory heat dissipation efficiency, etc. Achieve the effect of improving heat dissipation, low cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

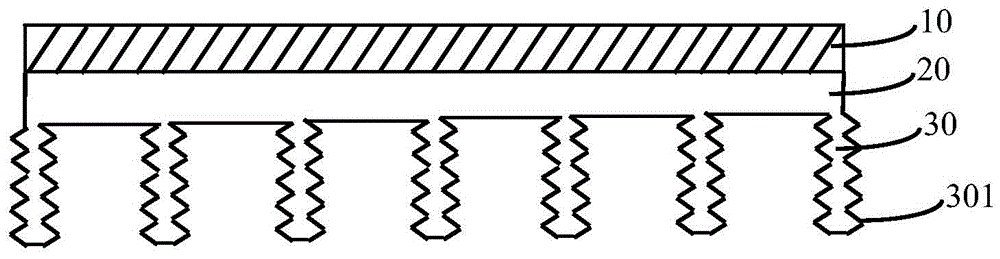

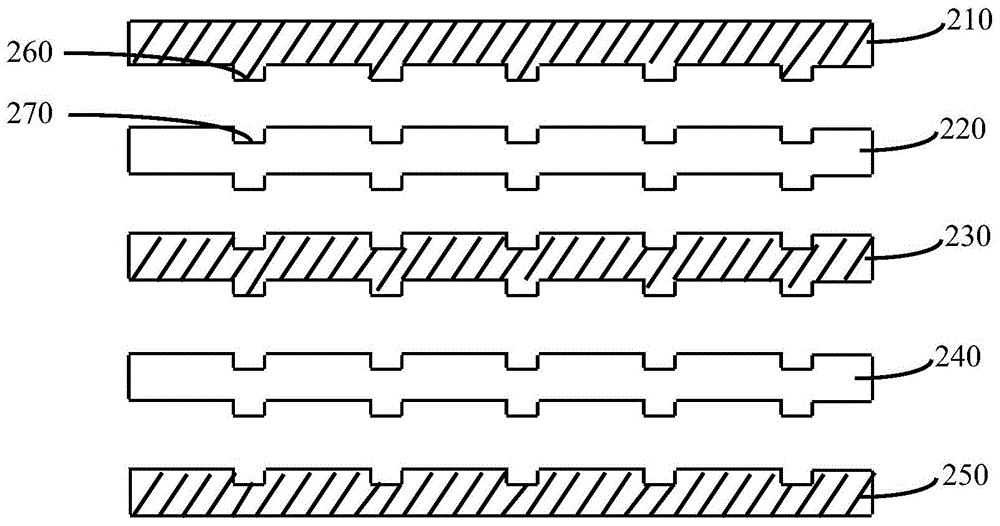

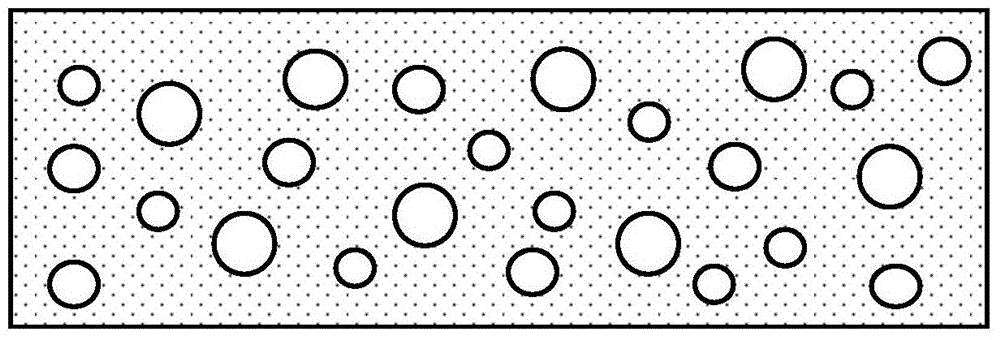

[0044] Another aspect of the present invention also provides a method for preparing a graphene heat sink, the method comprising the following steps: cleaning the substrate 20 with a two-dimensional or three-dimensional structure and drying it for later use. A compound formed of porous graphene and at least one polymer and / or polymer monomer is coated on the first surface of the substrate 20 to form the heat dissipation layer 10 . Hot pressing the composite-coated substrate 20 densifies the composite layer. A multi-layer structure including at least the first film layer 210 , the second film layer 220 , the third film layer 230 , the fourth film layer 240 and the fifth film layer 250 is sequentially arranged on the second surface opposite to the first surface. A plurality of cooling fins 30 are disposed on the surface of the fifth film layer 250 . A plurality of heat dissipation fins 301 are extended on each heat dissipation fin 30 . Preferably, in order to increase the stabi...

Embodiment 1

[0047] Take the formation and pretreatment of the substrate 20 with a two-dimensional or three-dimensional structure as an example.

[0048] The substrate 20 can be any two-dimensional planar structure, and the substrate 20 can also be a three-dimensional structure. Preferably, the material of the substrate 20 is selected from any one or alloys of aluminum, copper, titanium, stainless steel and nickel. The three-dimensional structure of the substrate 20 includes, but is not limited to, a convex structure, a concave structure, a hole structure, a curved surface structure, a grating structure, an optical waveguide structure, a photonic crystal structure and a fishnet structure. The size of the two-dimensional or three-dimensional structure of the substrate 20 is nano-scale, micro-scale or macro-scale.

[0049] According to the material properties of the substrate 20 and the required structural size, select photolithography, dry etching, wet etching, nanoimprinting, masking, ion...

Embodiment 2

[0060] This embodiment is a further improvement on Embodiment 1, and only the improved part will be described.

[0061] The material of the substrate 20 is not limited to metal material, and may also be plastic with high thermal conductivity, or PCB with high thermal conductivity. The material of the substrate 20 may also be a structural polymer with high thermal conductivity, such as polyacetylene, polyaniline, polypyrrole and the like with good thermal conductivity. The material of the substrate 20 can also be a metal with high thermal conductivity or a polymer material filled with inorganic fillers.

[0062] According to a preferred embodiment, the material of the substrate 20 is a metal-filled polymer-based thermally conductive composite material. Preferably, the commonly used metal material is one of silver, copper, tin, aluminum, nickel and iron. Preferably, the material of the substrate 20 is a thermally conductive composite material made by filling HDPE resin with al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com