Preparation method of thermal conduction enhanced metal organic framework gas storage material

A metal-organic framework and enhanced thermal conductivity technology, which can be applied to 4/14 groups of organic compounds without C-metal bonds, 6/16 groups of organic compounds without C-metal bonds, organic chemistry, etc. It can solve the problem of reducing the effective adsorption of gases. Quantity and other issues, to achieve the effect of mild reaction conditions, simple process and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

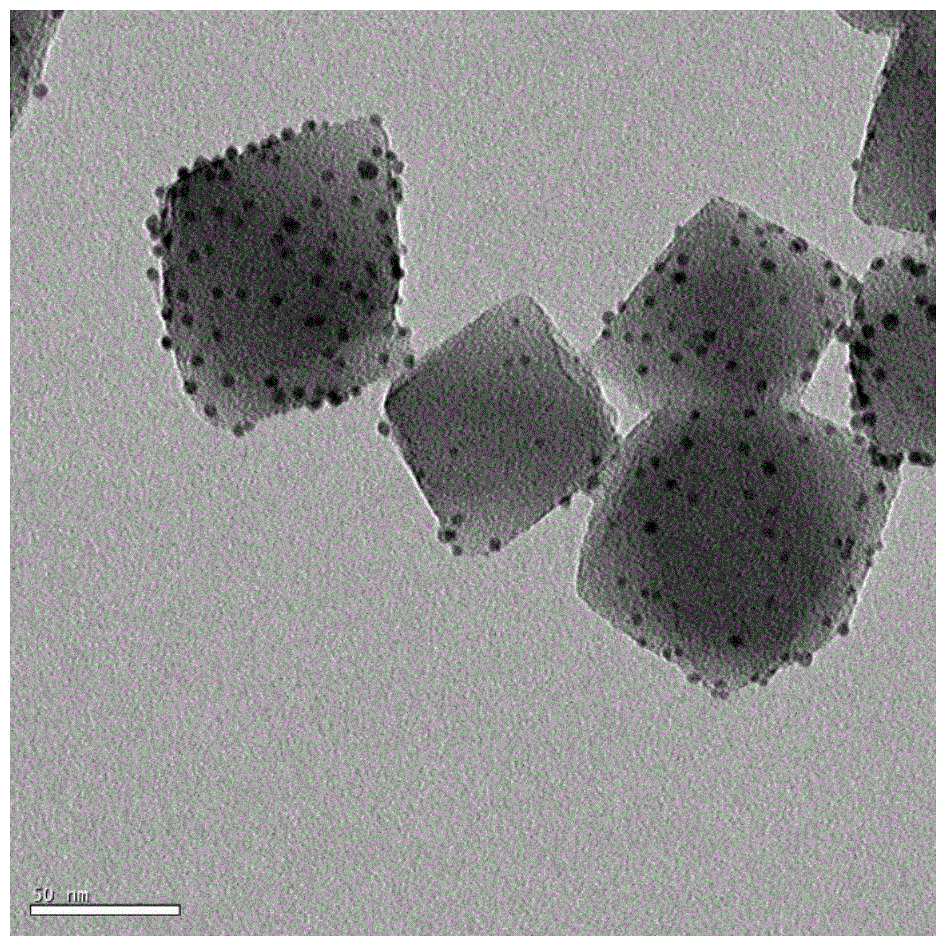

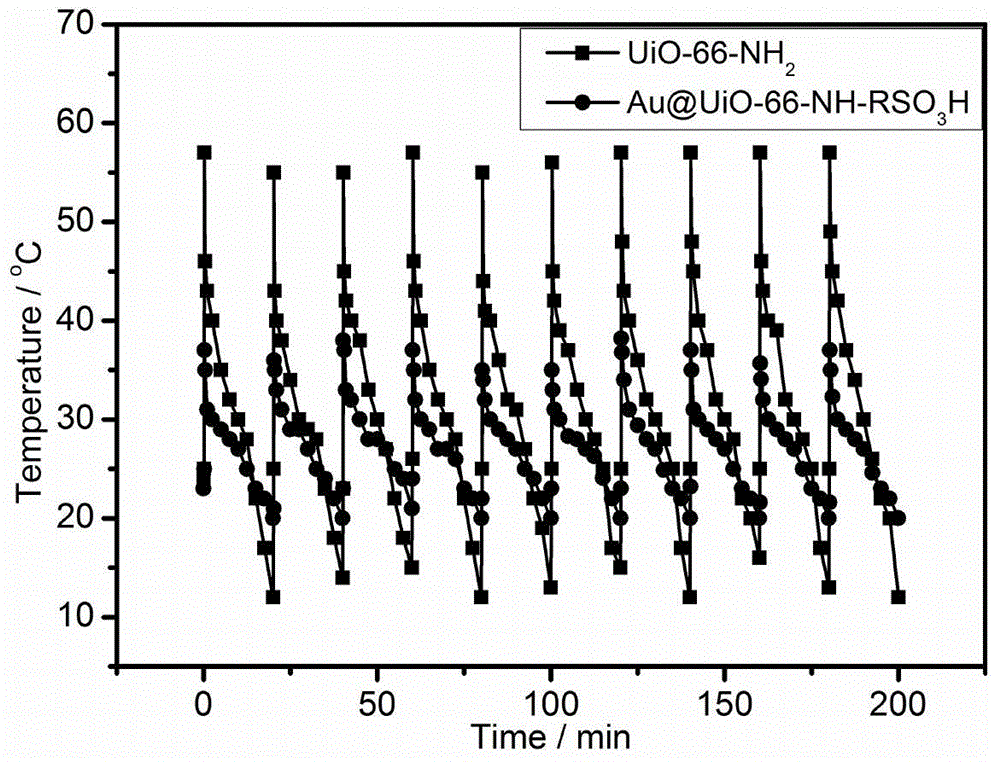

[0029] (1) ZrCl 4 (0.4g, 1.7mmol) was dissolved in 75mL of DMF, ultrasonically dispersed until dissolved; 2.85mL (850mmol) of acetic acid was added during ultrasonication; at the same time, aminoterephthalic acid (0.311g, 1.7mmol) was dissolved in 25mL of DMF At the same time, pour it into a 250mL round-bottomed flask, add 0.125mL (0.007mmol) of deionized water at the end, plug the bottle tightly, ultrasonically disperse at 60°C for a period of time, and then put it into an oil bath at 120°C Stand in the middle for 24h. After the reaction was finished, it was centrifuged, and the lower layer of precipitate was soaked in DMF for two hours, and then centrifuged. Then washed several times with ethanol and dried in vacuum at 150°C for 5h to obtain UiO-66-NH 2 .

[0030] (2) Take UiO-66-NH 2 (0.2g, 0.113mmol) was dissolved in 5mL of chloroform, and 1,3-propanesultone (0.144g, 1.18mmol) was added and stirred overnight. Subsequently, HAuCl was added to the reaction solution unde...

Embodiment example 2

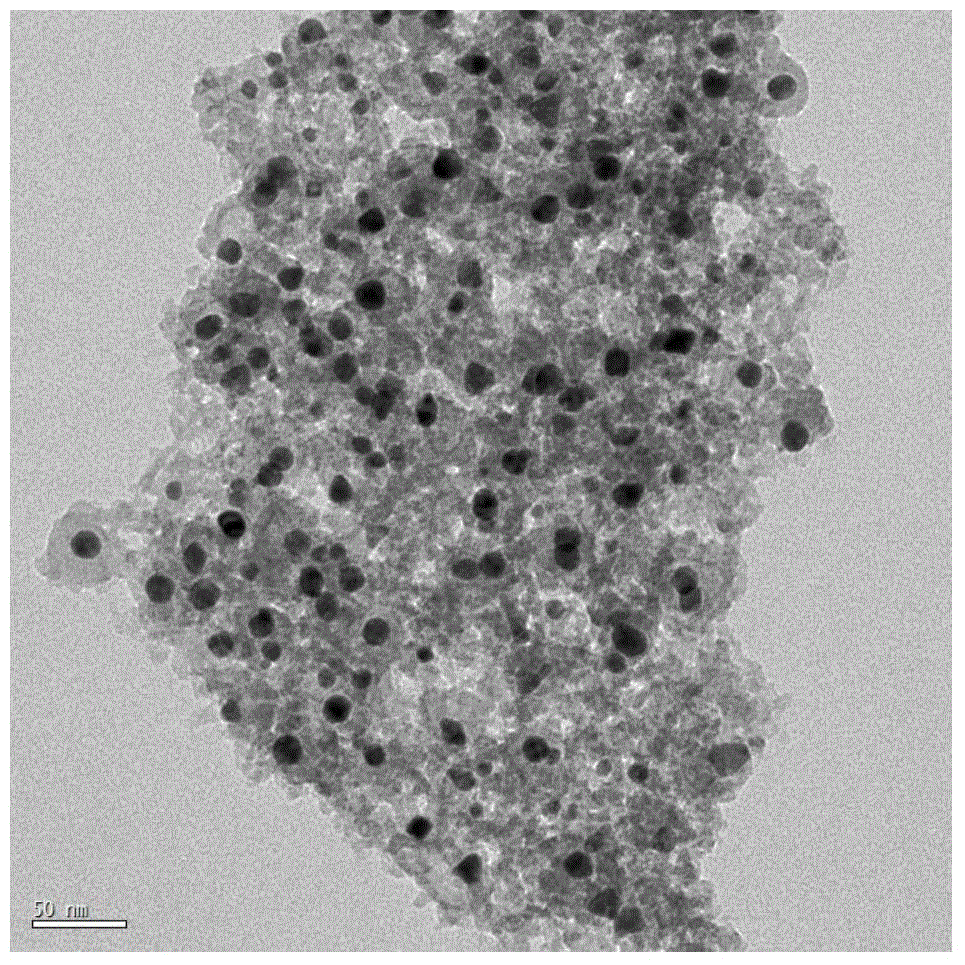

[0034] (1) CrCl 3 (0.27g) and 2-nitroterephthalic acid (0.21g) were fully dissolved in 5mL of deionized water, stirred at room temperature for 30min, moved to a 25mL reaction kettle, and reacted at 180°C for 96h. The product was centrifuged, washed with a mixed solvent of ethanol and water, and dried in a vacuum oven at 60°C for 24 hours to obtain MIL-101-NO 2 (Cr).

[0035] (2) Take MIL-101-NO 2 (Cr) (0.1g) and SnCl 2 2H 2 O (3.26g) was dissolved in 20mL of ethanol, stirred at 70°C for 6h, and then redispersed in 20mL of concentrated hydrochloric acid after centrifugation. After the reaction, the precipitate was obtained by centrifugation, and then dispersed in 25 mL of ethanol. In order to ensure the controllable reduction of gold nanoparticles in the MOFs pores, multiple adsorption and reduction methods were used to reduce the number of gold nanoparticles on the surface of MOFs materials. Add HAuCl in ice bath 4 Aqueous solution of precursor (0.3mL, 0.025M), stirring ...

Embodiment example 3

[0038] (1) Mix 2-aminoterephthalic acid (1.636g, 5.5mmol) with Zn(NO 3 ) 2 4H 2 O (0.37g, 2mmol) and 50mL DMF were mixed and stirred at room temperature for 30min, divided into 5 scintillation vials, kept in an oven at 55°C for 96h, and then CTAB (0.728g, 2mmol) was added to each scintillation vial55 ℃ heating and stirring until CTAB is completely dissolved, and then transferred to an oven at 105 ℃ for 90 minutes. Take out the scintillation vial, add TEA (0.278mL, 2mmol) respectively, stir for 10min, centrifuge, use solvent DMF, CHCl 3 Washed three times respectively, oven-dried at 40°C, and then vacuum-dried to obtain IRMOF-3.

[0039] (2) Disperse IRMOF-3 (0.27g, 0.27mmol) in 20mL CHCl 3 Glyoxal (220mg, 40wt% aqueous solution) was added dropwise at room temperature, and the reaction was stirred for 24h to modify the aldehyde group in the channel of IRMOF-3. Then add AgNO to the reaction vessel 3 Precursor aqueous solution (2.5mL, 0.025M), stirred and adsorbed for 4h, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com