Power generation system using exhausting and cooling waste heat in internal combustion engine at the same time and control method therefor

A technology of power generation system and internal combustion engine, which is applied in the control of coolant flow, cooling of engine, internal combustion piston engine, etc., can solve the problems of incapable of practical application, inability to make full use of internal combustion engine, large volume of refrigeration device, etc., and achieve saving The effect of consumption rate, high useful work output, and little damage to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

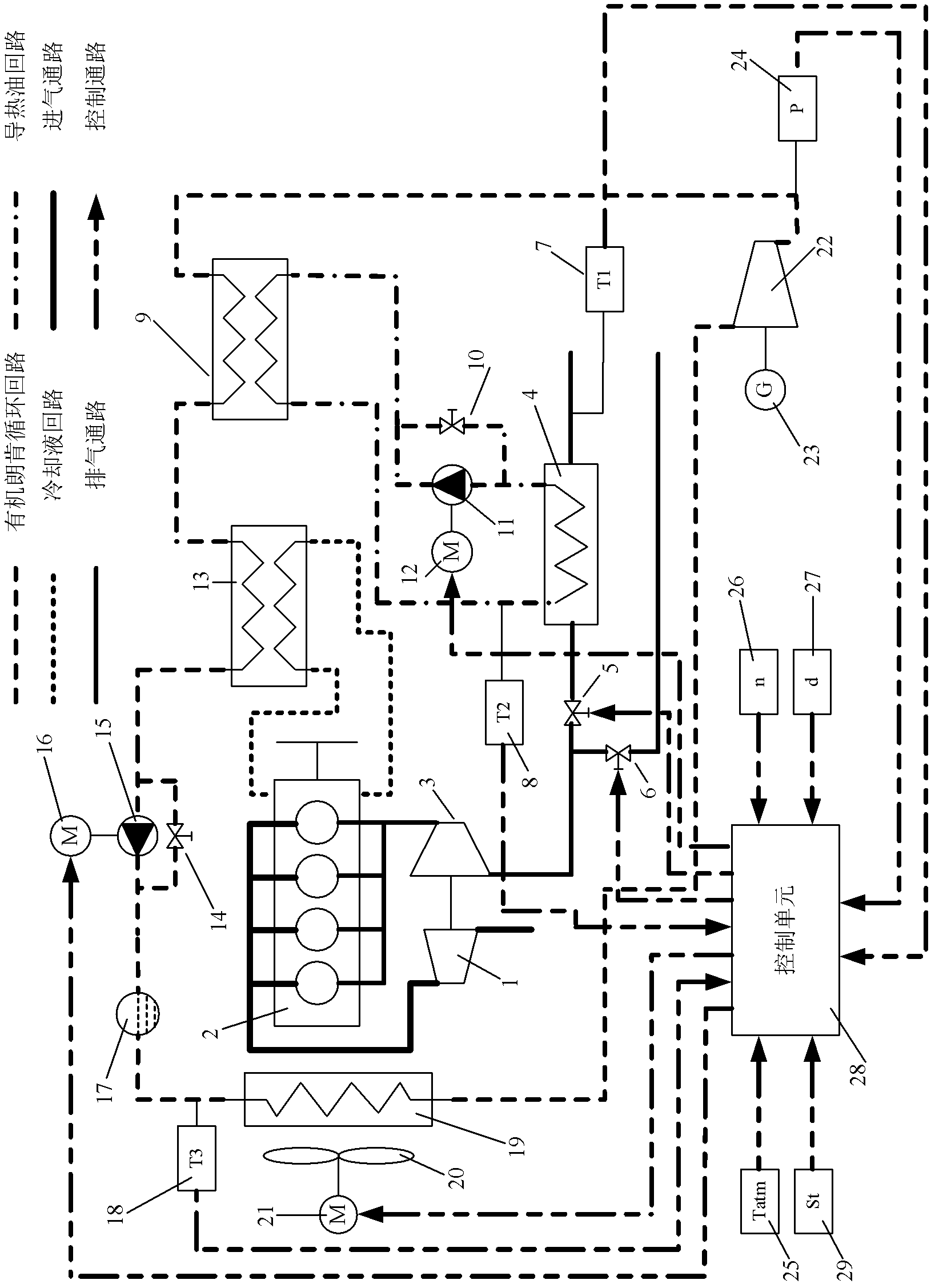

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

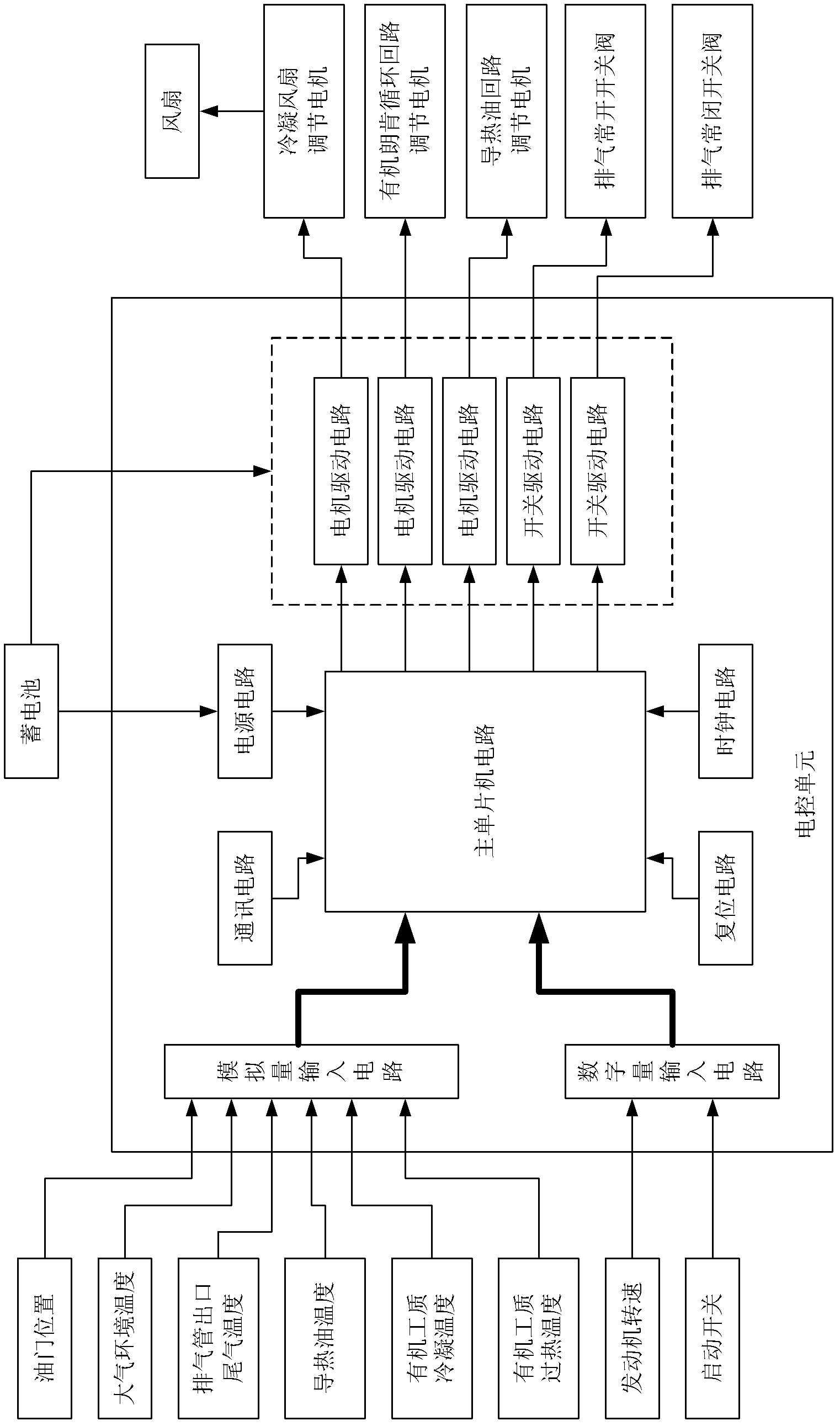

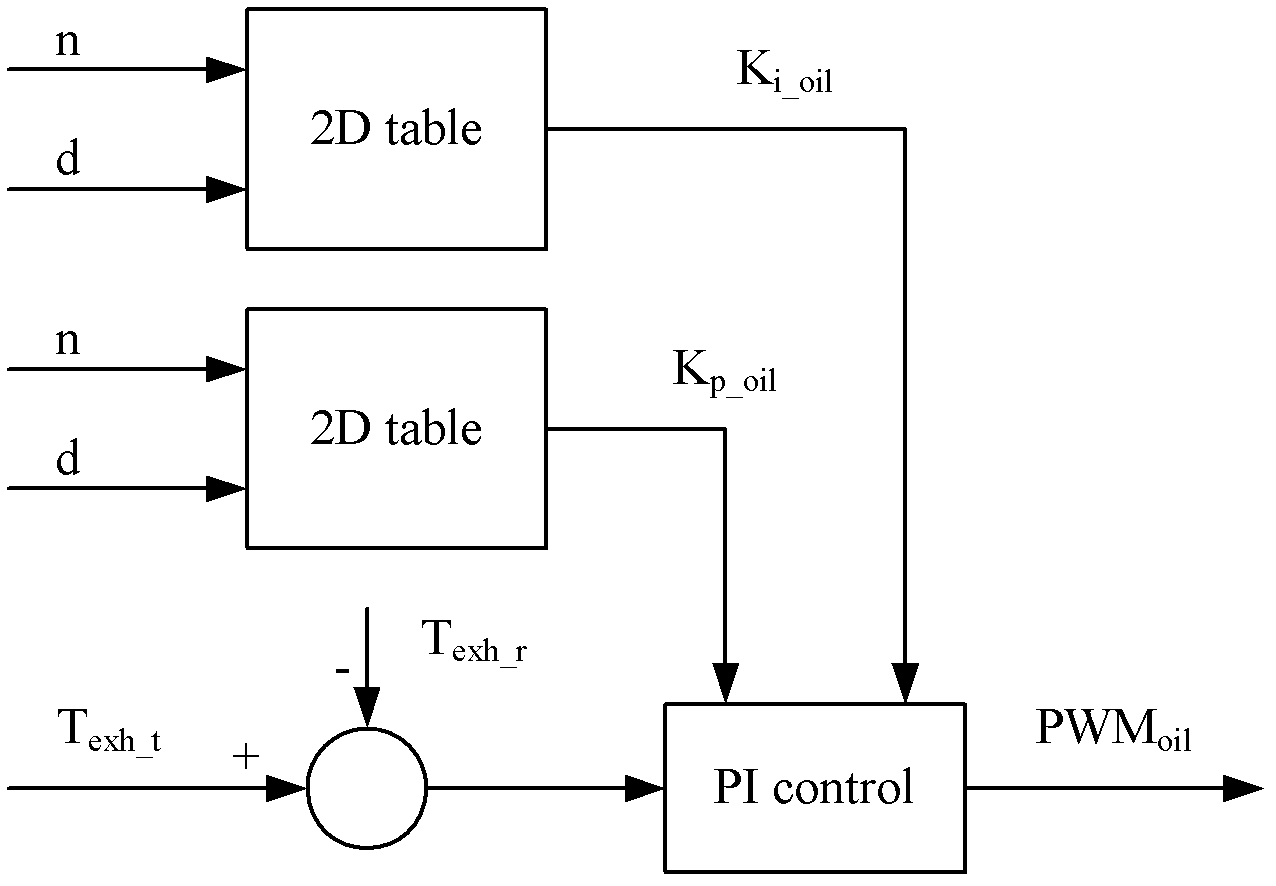

[0033] An organic Rankine cycle power generation system utilizing internal combustion engine exhaust and cooling waste heat at the same time according to the present invention, its connection diagram is as follows figure 1 Shown, including heat transfer oil loop, ORC loop and control pathway. The heat transfer oil circuit for absorbing the exhaust heat of the internal combustion engine includes the following components: working medium pump 11, regulating motor 12, pressure regulating valve 10, exhaust heat exchanger 4 and evaporator 9, exhaust normally open switch valve 5, Exhaust normally closed on-off valve 6 and the pipeline connecting them. The components included in the organic Rankine cycle circuit for recovering the waste heat of the internal combustion engine coolant and the heat transferred by the heat transfer oil include: a working medium pump 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com