Graphene nylon composite material and preparation method thereof

A nylon composite material and graphene technology are applied in the field of graphene-nylon composite materials and their preparation, which can solve the problems of poor wear resistance and thermal conductivity of nylon materials, and achieve improved thermal conductivity, good thermal conductivity, wear resistance, resistance to wear and tear. Abrasiveness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

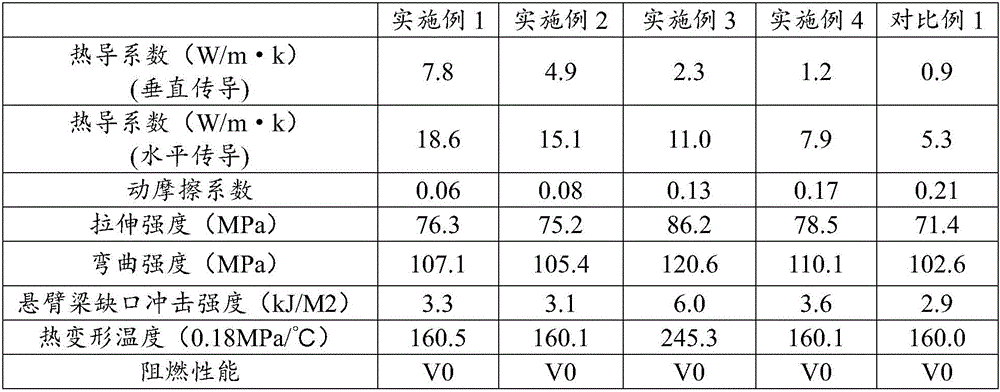

Examples

preparation example Construction

[0075] The invention also provides a preparation method of the graphene nylon composite material. The preparation method comprises the following steps:

[0076] S1, mixing nylon, graphene, anti-wear agent, thermally conductive filler, lubricating dispersant and additives to obtain a mixture;

[0077] S2, adding the above mixture into an extruder, melting and mixing the components in the mixture by shearing, and finally extruding and granulating through the head of the extruder to obtain a graphene nylon composite material.

[0078] In step S1, mixing various components can be realized by a mixer or an internal mixer.

[0079] In step S2, the mixture is fed into the main feeding port of the extruder, and the materials that cannot be fed through the main feeding port are fed through the middle feeding port or the side feeding port. The speed of the extruder is 400 rpm to 720 rpm, the temperature of the first zone of the screw of the extruder is 150°C to 250°C, the temperature ...

Embodiment 1

[0083] Mix 50% of nylon, 25% of graphene, 1.2% of anti-wear agent, 6.5% of toughening agent, 12% of flame retardant, 4% of lubricating and dispersing agent, and 1.3% of auxiliary agent. Wherein, the nylon is PA6; the wear-resistant agent is molybdenum disulfide; the thermally conductive filler is high thermally conductive graphite; the toughening agent is styrene butyl acrylate binary graft modified propylene rubber, and the The flame retardant is nitrogen-phosphorus composite flame retardant HFR-19; the lubricating dispersant is stearic acid; the auxiliary agent is 0.3% of 168 antioxidant and 1% of silane coupling agent.

[0084] Melt, knead, extrude, cool, dry, and pelletize the mixture obtained above through a twin-screw extruder to obtain a graphene-nylon composite material. Wherein, the temperature of each zone in the extruder is as follows: the temperature of the first zone is 150°C to 200°C, the temperature of the second zone to the sixth zone is 220°C to 245°C, the tem...

Embodiment 2

[0086] Mix 50% of nylon, 15% of graphene, 1.2% of anti-wear agent, 10% of thermally conductive filler, 6.5% of toughening agent, 12% of flame retardant, 4% of lubricating and dispersing agent, and 1.3% of auxiliary agent. Wherein, the nylon is PA6; the wear-resistant agent is molybdenum disulfide; the thermally conductive filler is high thermally conductive graphite; the toughening agent is styrene butyl acrylate binary graft modified propylene rubber, and the The flame retardant is nitrogen-phosphorus composite flame retardant HFR-19; the lubricating and dispersing agent is stearic acid; the auxiliary agent is 0.3% of antioxidant BHT and 1% of silane coupling agent.

[0087] Melt, knead, extrude, cool, dry, and pelletize the mixture obtained above through a twin-screw extruder to obtain a graphene-nylon composite material. Wherein, the temperature of each zone in the extruder is as follows: the temperature of the first zone is 150°C to 200°C, the temperature of the second zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com