Method for preparing high activity non-metallic ion co-doped titanium dioxide photochemical catalyst

A titanium dioxide and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of low visible light catalytic efficiency, high cost or equipment requirements, complicated preparation method procedures, etc., and achieve enhanced visible light response, low equipment requirements, and high UV-visible photocatalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

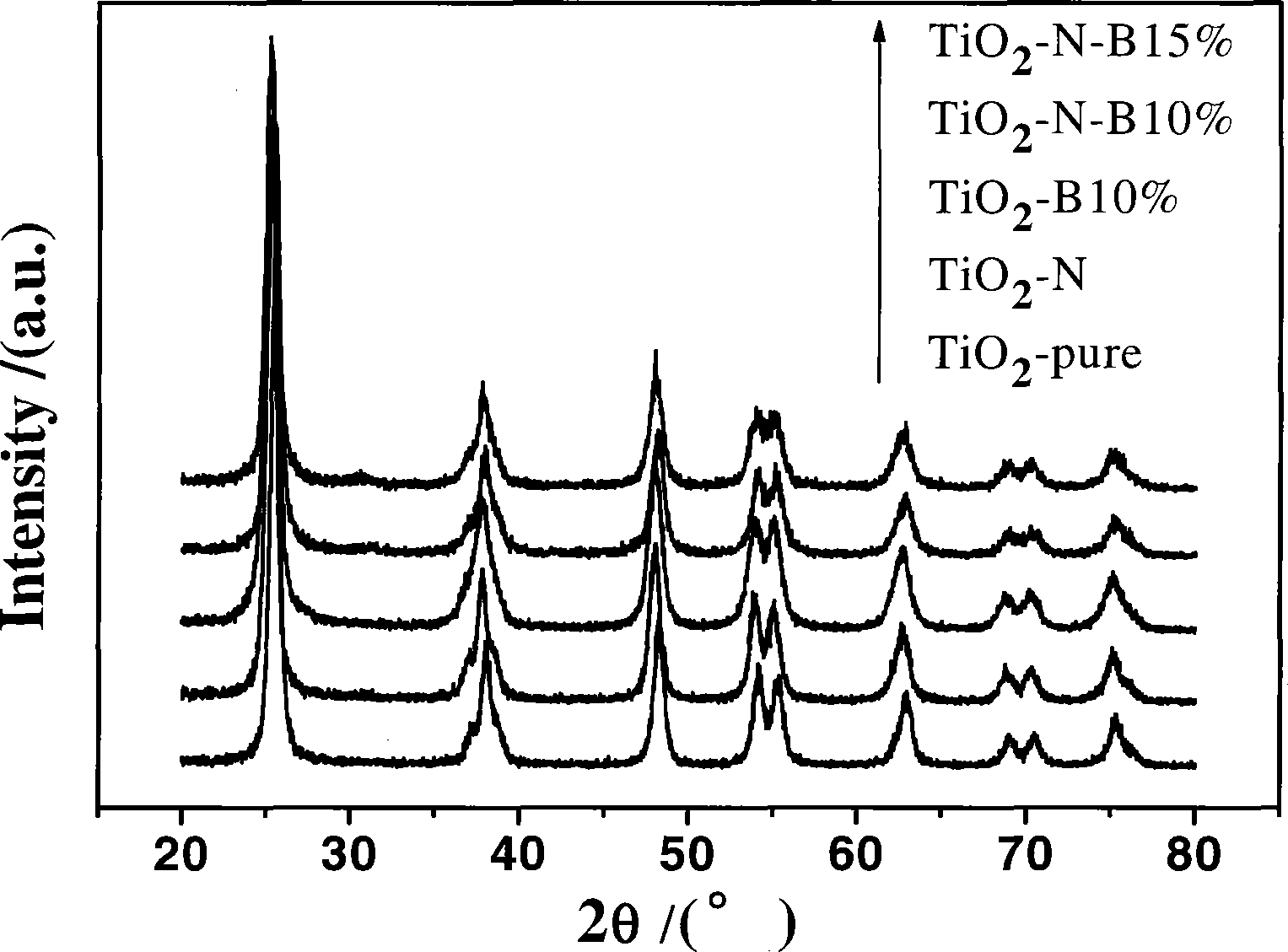

[0016] (1) TiO 2 -Preparation of pure catalyst

[0017] Preparation steps and TiO 2-x-y A x m y Similar, except that no non-metallic compound is added, and in step ②, after adding an acidic catalyst to the system, add a quantitative amount of high-purity water (18.2MΩ·cm -1 ).

[0018] (2)TiO 2 Preparation of -N catalyst

[0019] Preparation steps and TiO 2-x-y A x m y Similar, except that non-metallic compounds are not added in step ①, and a certain amount of nitrogen-containing compounds are added in step ③.

[0020] (3) TiO 2 Preparation of -B catalyst

[0021] Preparation steps and TiO 2-x-y A x m y Similar, only a certain amount of boron-containing compounds are added in step ①, and non-metallic compounds are not added in step ③.

[0022] 3. In the above preparation process, the addition amount of various reactants is:

[0023] The molar ratio of non-metallic compound to titanate or titanate is 1:20-10:1;

[0024] The volume ratio of diluent to titanate o...

Embodiment 1

[0044] At room temperature, measure 40ml of absolute ethanol and place it on a magnetic stirrer, measure 2ml of tetraethyl orthosilicate (8.65×10 -3 mol) was added absolute ethanol, fully stirred for 15 minutes to completely dissolve it; added 1ml hydrochloric acid (analytical pure); slowly dripped 12ml concentration of 98% tetrabutyl titanate (3.46 × 10 -2 mol), stirred evenly for 15 minutes; adding 3ml of ammonia water (0.04mol) with a concentration of 25%, stirred vigorously and uniformly at room temperature for 6-12 hours, left to stand and aged for 1-5 days, and obtained a precipitate; the precipitate Place it in an oven at 100°C for 10 hours to evaporate the solvent, grind it into powder with an agate mortar, put it into a crucible and calcinate it in an air atmosphere at 450°C in a muffle furnace for 2.5 hours to obtain nano-scale double non-metallic elements silicon and nitrogen. Doped TiO 2 catalyst of light.

Embodiment 2

[0046] At room temperature, measure 40ml of absolute ethanol and place it on a magnetic stirrer, weigh 1.39g bromine simple substance (8.65×10 -3 mol) was added absolute ethanol, fully stirred for 15 minutes to completely dissolve it; added 1ml hydrochloric acid (analytical pure); slowly dripped 12ml concentration of 98% tetrabutyl titanate (3.46 × 10 -2 mol), stirred evenly for 15 minutes; added 3.05g thiourea (0.04mol), stirred vigorously and uniformly at room temperature for 6-12 hours, left to age for 1-5 days, and obtained a precipitate; the precipitate was placed in an oven Bake at 100°C for 10 hours to evaporate the solvent, grind it into powder with an agate mortar, put it into a crucible and calcinate in the air atmosphere of 450°C in a muffle furnace for 2.5 hours to obtain nano-scale double non-metal element bromine and sulfur co-doped TiO 2 catalyst of light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com