Preparation methods of graphene and graphene-oxide compound

A graphene and oxide technology, applied in the field of new functional carbon materials, can solve the problems of easy aggregation of metal oxide particles, uneven particle size, easy aggregation of graphene, etc., and achieve uniform size, low cost, and sufficient reduction reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

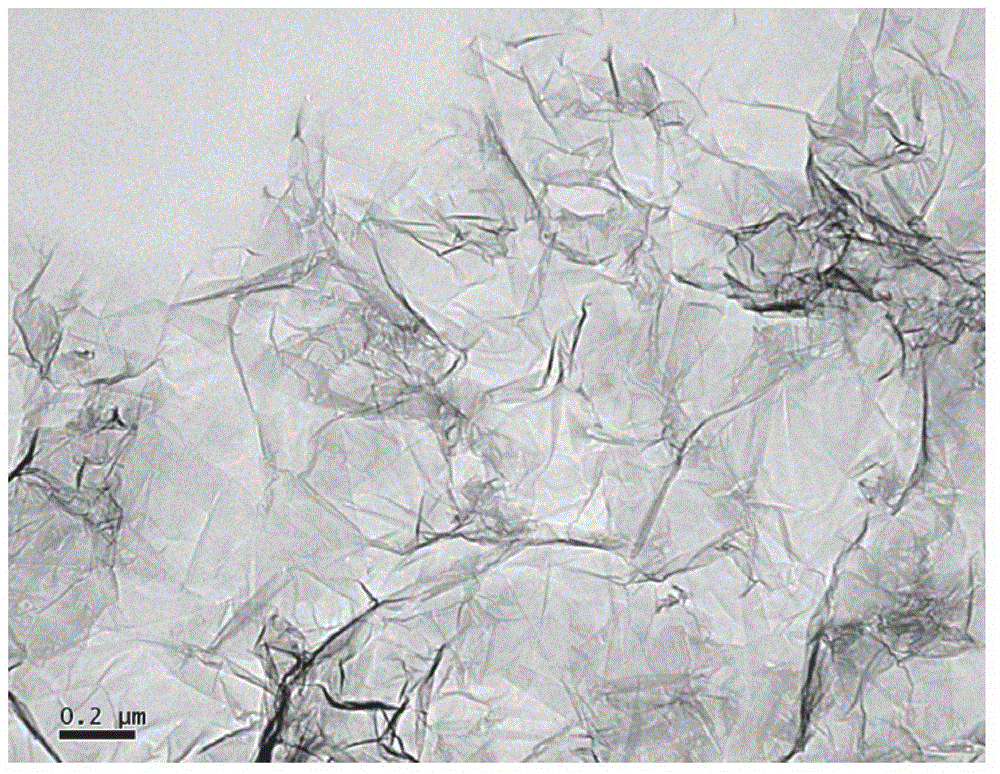

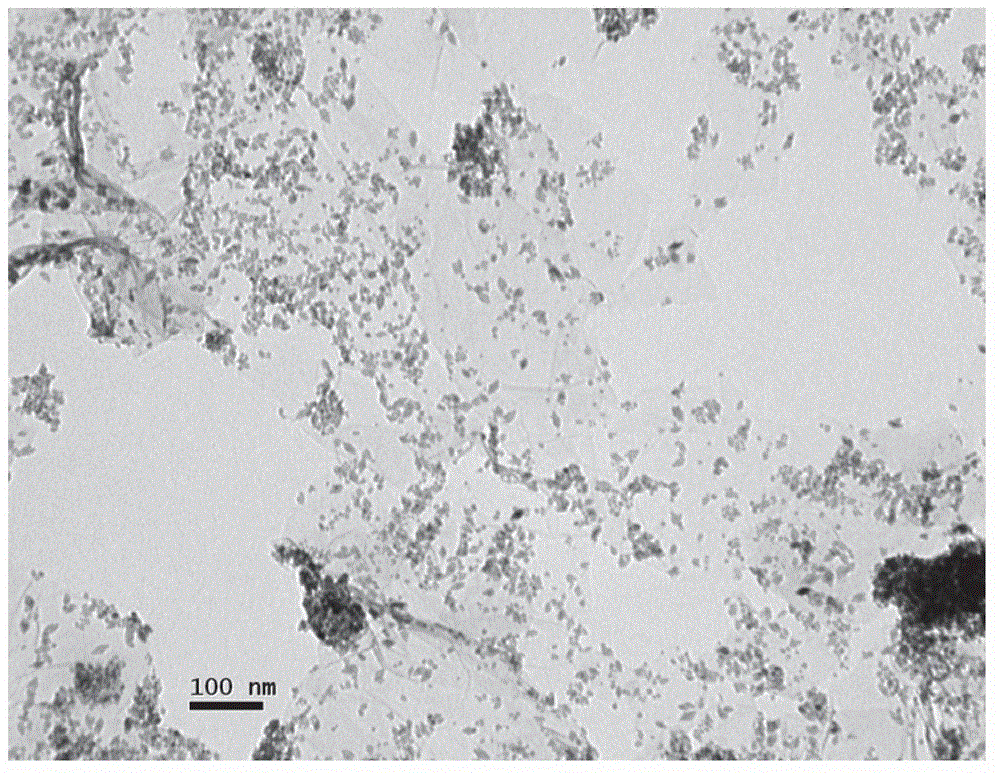

[0034] See figure 1 , the invention provides a kind of preparation method of graphene, comprises the following steps: (1) prepares graphene:

[0035]Weigh a certain amount of catechol or catechol derivatives, dissolve in a solvent to obtain a solution of catechol or its derivatives with a mass concentration of 0.05g / ml, grind graphene oxide into powder, and weigh a certain amount Graphene oxide powder is added to the solution of catechol or its derivatives, and after magnetic stirring to disperse evenly, ultrasonically disperse for 0.5-4 hours, transfer the dispersion liquid into a high-pressure reactor, and place the high-pressure reactor in a water bath at 80-200°C After hydrothermal reaction for 12-48 hours, the sample was filtered, washed with water, and dried in vacuum to obtain graphene.

[0036] The catechol derivative described in the step (2) is one of dopamine, α-methyldopamine, dihydroxyphenylalanine; the described solvent is water, methanol, ethanol, isopropanol, ...

Embodiment 2

[0047] The preparation method for preparing graphene and graphene-oxide composite that present embodiment provides is basically the same as embodiment 1, and its difference is:

[0048] The preparation method of described graphene is realized through the following steps:

[0049] (1) Graphite oxidation:

[0050] In an ice-water bath at -4°C, add 3g of graphite and 1.5g of sodium nitrate into a 500ml three-necked flask, slowly add 120mL of concentrated sulfuric acid with a mass fraction of 98% and 18g of potassium permanganate under stirring, and then raise the temperature to a constant temperature water bath of 35°C Stir for 0.5h, then slowly add 140mL of deionized water to dilute, stir for 10 minutes, add 120ml of hot water at 60°C, continue stirring for 10 minutes, add 30mL of 30% H 2 o 2 , filtered after standing still, fully washed the filter cake until neutral, then dispersed the filter cake in water, ultrasonicated for 6 hours, and vacuum-dried at 45°C to obtain graphe...

Embodiment 3

[0054] The preparation method for the preparation of graphene and graphene-oxide compound that present embodiment provides is basically the same as embodiment 1, 2, and its difference is:

[0055] A kind of preparation method of graphene, realizes by following steps:

[0056] (1) Graphite oxidation:

[0057] Add 4g of graphite and 2g of sodium nitrate into a 500ml three-necked flask in an ice-water bath at -4~0°C, slowly add 150mL of concentrated sulfuric acid with a mass fraction of 98% and 12g of potassium permanganate under stirring, and then raise the temperature to 35°C to keep the temperature Stir in a water bath for 1 hour, then slowly add 160 mL of deionized water to dilute, stir for 10 minutes, add 160 mL of hot water at 60°C, continue stirring for 10 minutes, add 22.75 mL of 30% H 2 o 2 , filtered after standing still, fully washed the filter cake until neutral, then dispersed the filter cake in water, ultrasonicated for 6 hours, and vacuum-dried at 45°C to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com