Preparation method of non-enzyme glucose sensor electrode material based on CuO film

A technology of glucose sensor and electrode material, applied in the field of electrochemical material preparation, can solve the problems affecting the practicability of non-enzyme glucose sensor, electrode stability and poor electrocatalytic activity, and achieves reproducibility, reusability and simple structure. , the effect of orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) The ITO conductive glass is ultrasonically cleaned by acetone, ethanol, and deionized water for 20 minutes each, and dried with nitrogen to form a clean substrate for use;

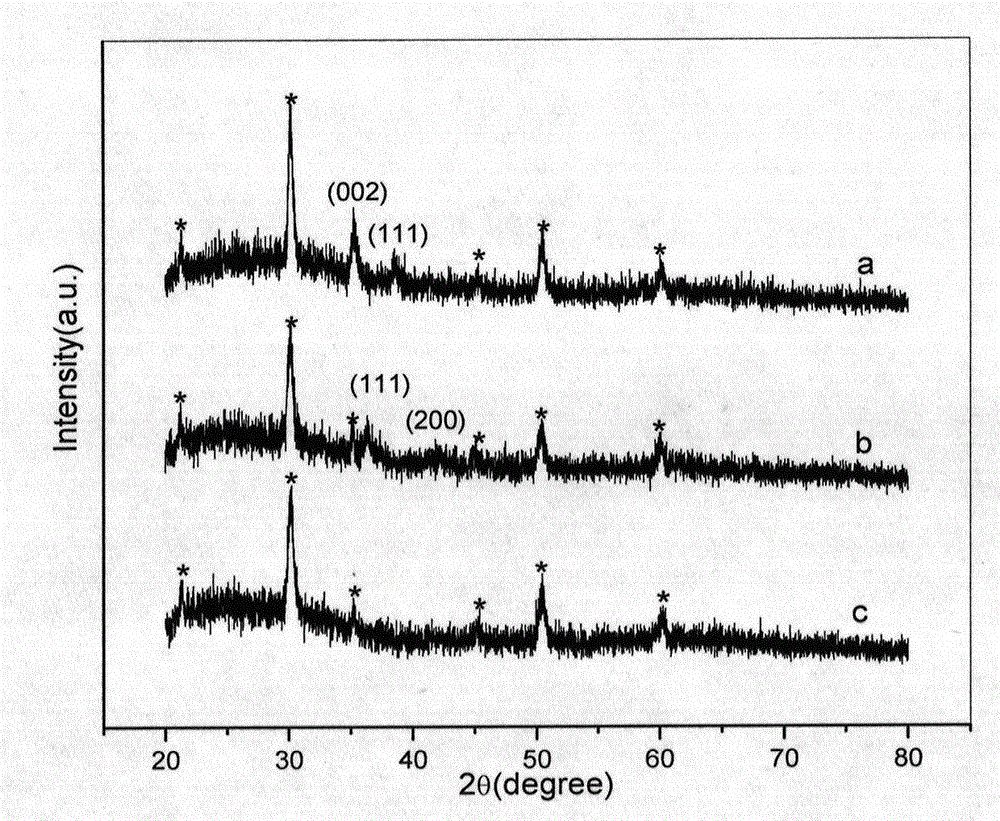

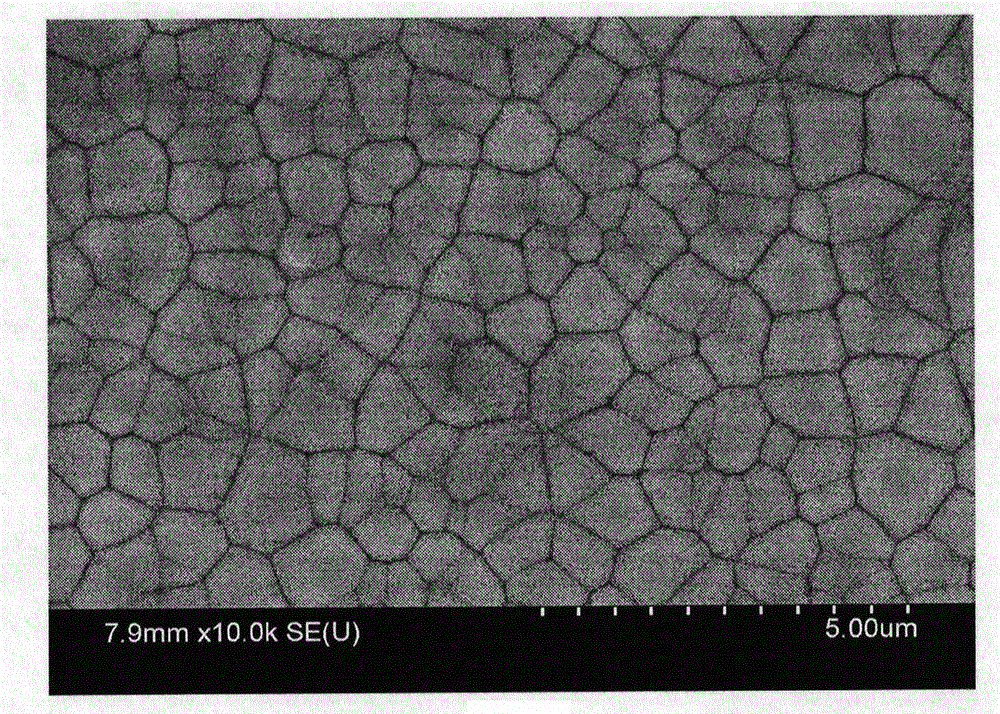

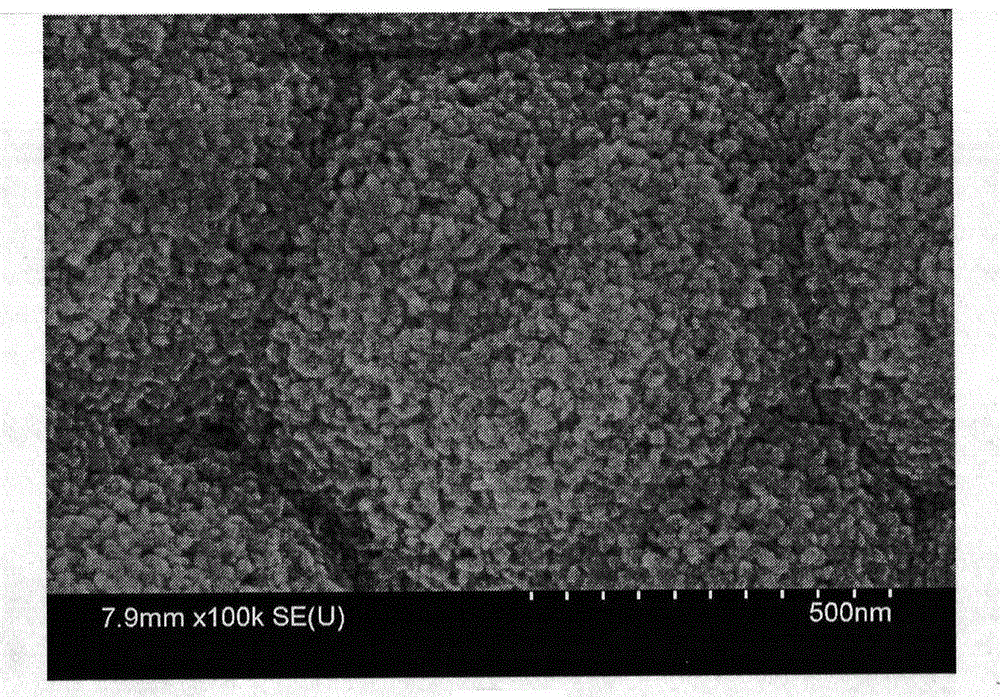

[0024] (2) Electrochemical deposition method was used to prepare cuprous oxide film. The experimental conditions were: the electrolyte used was a mixture of copper acetate, sodium acetate and cetyltrimethylammonium bromide, and the concentration of copper acetate was 0.02mol / L, the concentration of sodium acetate is 0.08mol / L, and the concentration of cetyltrimethylammonium bromide is 0.002mol / L; the electrolyte temperature is controlled at 60°C by a constant temperature water bath, and the three-electrode electrochemical cell is used for deposition. The electrode is ITO conductive glass, the counter electrode is a platinum sheet electrode, and the reference electrode is an Ag / AgCl electrode. The three electrodes were inserted into the solution, a constant voltage of -0.2V was applied, and the ...

Embodiment 2

[0027] (1) The FTO conductive glass was ultrasonically cleaned by acetone, ethanol, and deionized water for 20 minutes each, and dried with nitrogen to form a clean substrate for use;

[0028] (2) Electrochemical deposition method was used to prepare cuprous oxide film. The experimental conditions were: the electrolyte used was a mixture of copper acetate, sodium acetate and cetyltrimethylammonium bromide, and the concentration of copper acetate was 0.02mol / L, the concentration of sodium acetate is 0.04mol / L, and the concentration of cetyltrimethylammonium bromide is 0.02mol / L; the electrolyte temperature is controlled at 70°C by a constant temperature water bath, and the three-electrode electrochemical cell is used for deposition. The electrode is FTO conductive glass, the counter electrode is platinum sheet electrode, and the reference electrode is Ag / AgCl electrode. Insert the three electrodes into the solution, apply a constant voltage of -0.25V, and deposit for 10 minute...

Embodiment 3

[0031] (1) The ITO conductive glass is ultrasonically cleaned by acetone, ethanol, and deionized water for 20 minutes each, and dried with nitrogen to form a clean substrate for use;

[0032](2) Electrochemical deposition method was adopted to prepare cuprous oxide film. The experimental conditions were: the electrolyte used was a mixture of copper acetate, acetic acid and sodium lauryl sulfate, the concentration of copper acetate was 0.02mol / L, and the concentration of acetic acid was 0.06mol / L, the concentration of sodium lauryl sulfate is 0.008mol / L; the temperature of the electrolyte is controlled at 20°C by a constant temperature water bath, and a three-electrode electrochemical cell is used for deposition. The working electrode is ITO conductive glass, and the counter electrode is platinum. Sheet electrode, the reference electrode is Ag / AgCl electrode. The three electrodes were inserted into the solution, a constant voltage of -0.3V was applied, and the deposition time w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com