Inorganic composite flexible decorative coiled materials and producing method thereof

A technology of composite flexible and decorative coils, applied in chemical instruments and methods, hydraulic material layered products, layered products, etc. The effect of strong anti-ultraviolet penetration ability, excellent weather resistance and self-cleaning, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

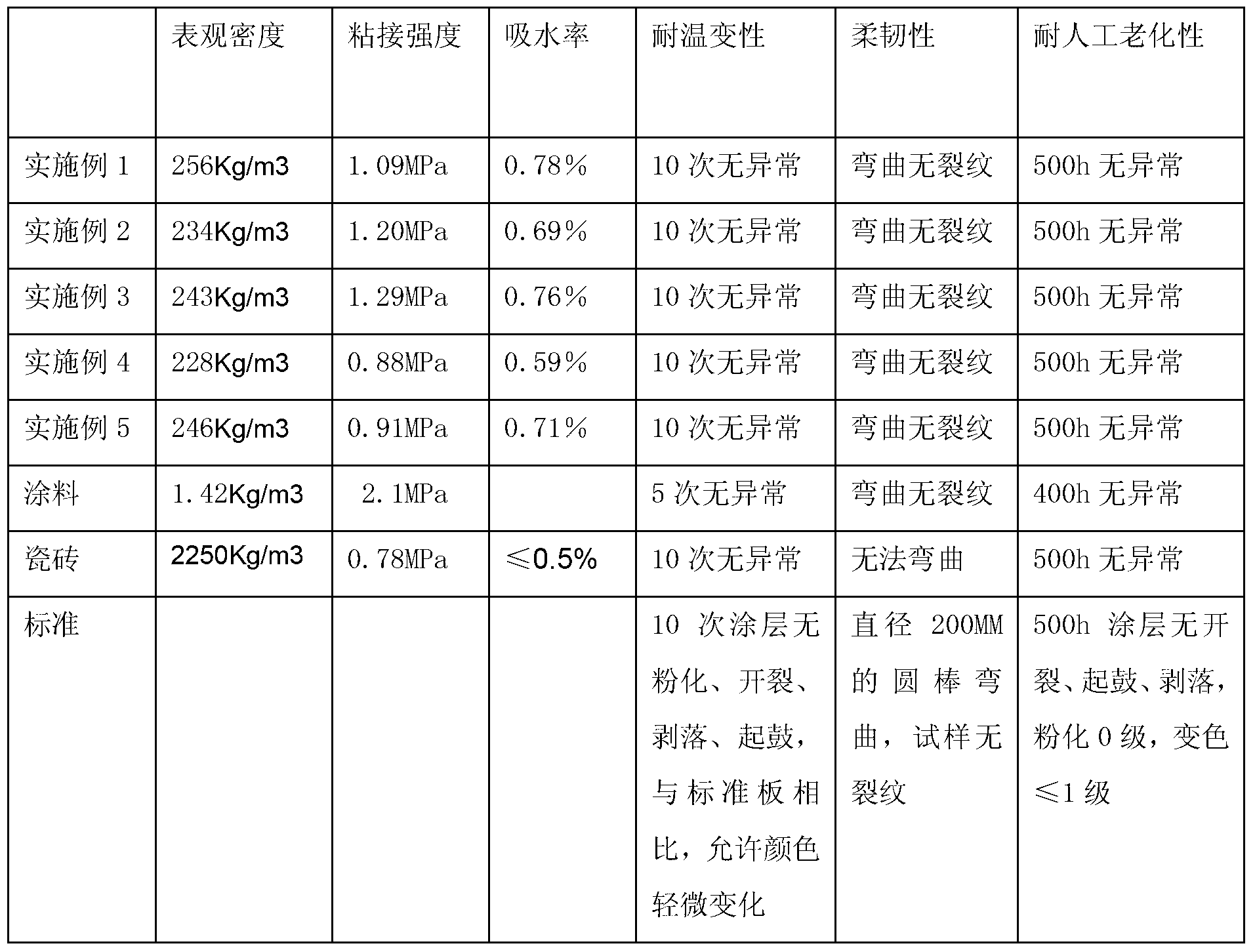

Examples

Embodiment 1

[0040] The mortar formula used for the inorganic coiled mortar layer is:

[0041] Ordinary Portland cement 42.5 100kg,

[0042] Hydroxypropyl methylcellulose 1.6kg,

[0043] 50-100 mesh quartz sand 400kg,

[0044] 200 mesh heavy calcium 200kg,

[0045] Water reducer 2kg,

[0046] 707 emulsion 140kg.

[0047] Preparation of inorganic coiled material mortar layer: weigh the above raw materials in proportion, add 160kg of water and mix and stir until it becomes a paste, coat the paste-like inorganic coiled material mortar on the alkali-resistant glass fiber mesh cloth or glass fiber roofing mat, bake Dry to form an inorganic flexible membrane.

[0048] The formula used for the decorative mortar layer is:

[0049] Polymer emulsion (brand BA107, manufacturer Beijing Donglian Chemical Co., Ltd.) 150kg,

[0050] Coalescing agent (brand alcohol ester 12, manufacturer Beijing Oriental Tomorrow Chemical Co., Ltd.) 5kg,

[0051] Ethylene glycol 10kg,

[0052] Hydroxyethylcellulose...

Embodiment 2

[0056] The total thickness is 5mm.

[0057] Mortar formula for inorganic coiled material mortar layer:

[0058] Ordinary Portland cement 42.5 100kg,

[0059] Hydroxyethylcellulose 1.6kg,

[0060] 50-100 mesh quartz sand 400kg,

[0061] 200 mesh heavy calcium 200kg,

[0062] Water reducer 2kg,

[0063] Cement-based elastic emulsion emulsion 140kg.

[0064] The formula used for the decorative mortar layer is:

[0065] BA107 emulsion 150kg,

[0066] Coalescing aid 5kg,

[0067] Ethylene glycol 10kg,

[0068] Hydroxypropyl methylcellulose 1.5kg,

[0069] Natural colored sand 750kg.

Embodiment 3

[0071] The total thickness of the coil is 5mm.

[0072] Ordinary Portland cement 42.5 100kg,

[0073] Hydroxypropyl methylcellulose 1.2kg,

[0074] 50-100 mesh quartz sand 350kg,

[0075] 200 mesh heavy calcium 220kg,

[0076] Water reducer 1.8kg,

[0077] 707 emulsion 120kg.

[0078] The formula used for the decorative mortar layer is:

[0079] Polymer emulsion (brand BA107, manufacturer Beijing Donglian Chemical Co., Ltd.) 150kg,

[0080] Coalescing agent (brand alcohol ester 12, manufacturer Beijing Oriental Tomorrow Chemical Co., Ltd.) 4kg,

[0081] Ethylene glycol 8kg,

[0082] Hydroxyethylcellulose 2kg,

[0083] Natural colored sand 700kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com