Vegetable dehydrator adopting stiffener chain plates

A technology for dehydrating vegetables and reinforcing rods, which is applied in applications, food processing, food science, etc., can solve the problems of chain plate shedding, poor rigidity, and easy deformation, and achieve the effects of ensuring normal operation, improving rigidity, and ensuring the quality of dried vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

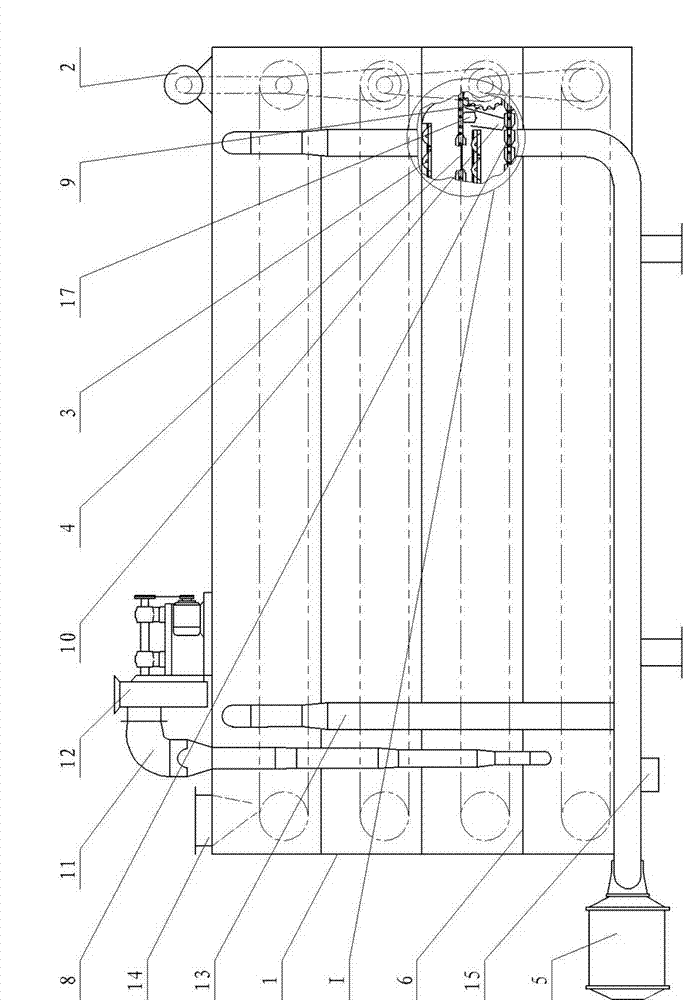

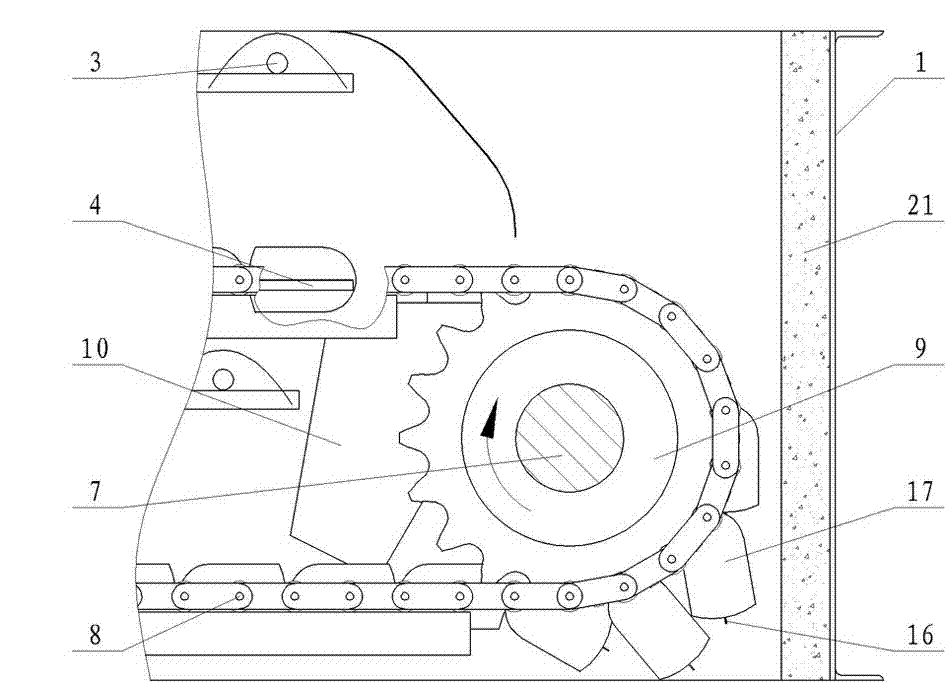

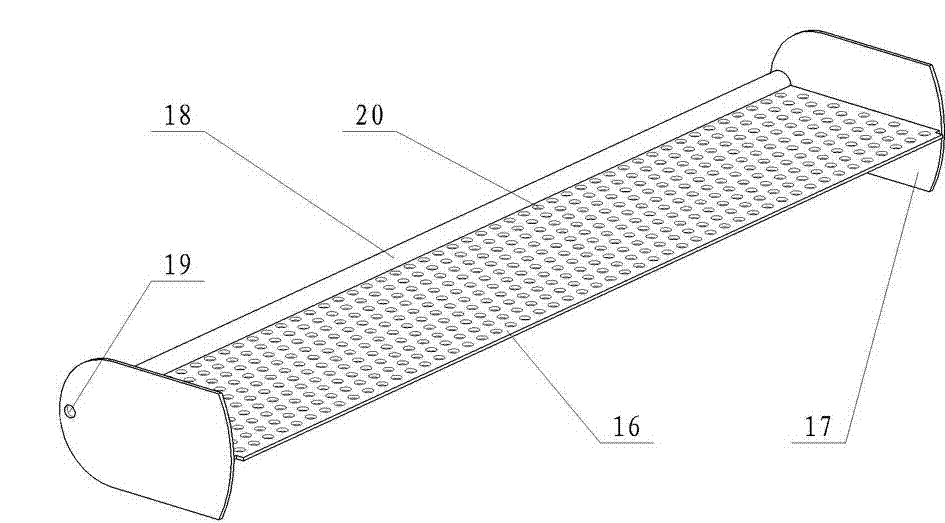

[0025] 1. Box 2, transmission device 3, infrared radiation device 4, guide rail 5, air heater 6, clapboard 7, shaft 8, conveying chain 9, conveying sprocket 10, material guide trough 11, air duct 12, fan 13. Air supply pipe 14, material inlet 15, material outlet 16, panel 17, baffle plate 18, reinforcing rod 19, hanging hole 20, ventilation hole 21, insulation layer.

[0026] exist Figure 1~5 , Figure 7~9In the shown embodiment: the transmission device 2 of the reinforcing rod chain plate vegetable dehydrator is installed at one end of the top of the box body 1, and the other end is provided with a feed port 14, and the same end is provided with a discharge port 15 at the bottom of the box body 1 ; The box body 1 is horizontally divided into four layers by partitions 6, and the layer numbers of each layer from top to bottom are Ⅰ, Ⅱ, Ⅲ, Ⅳ in sequence, and a group of gears driven by the transmission device 2 are arranged in each layer. Conveyor device; the reinforcing bar c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com