Integrated turning force measuring tool system with embedded film sensors

A thin-film sensor and tool system technology, applied in turning equipment, measuring/indicating equipment, manufacturing tools, etc., can solve the problems of limited application scope and low measurement accuracy of turning force measurement technology, achieving no hysteresis and solving measurement problems. The effect of low accuracy and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

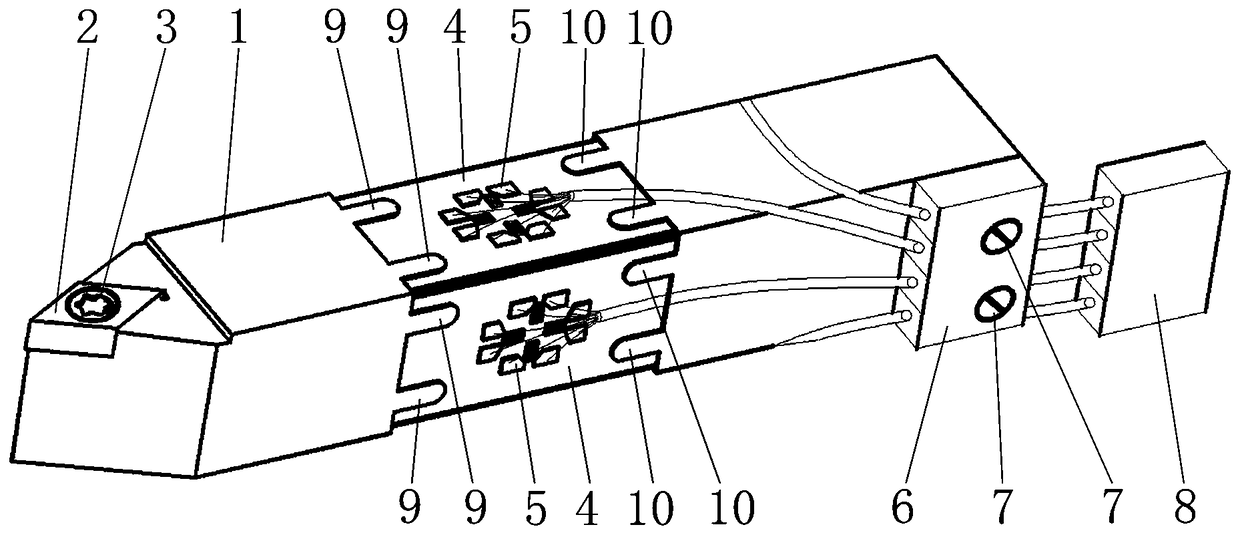

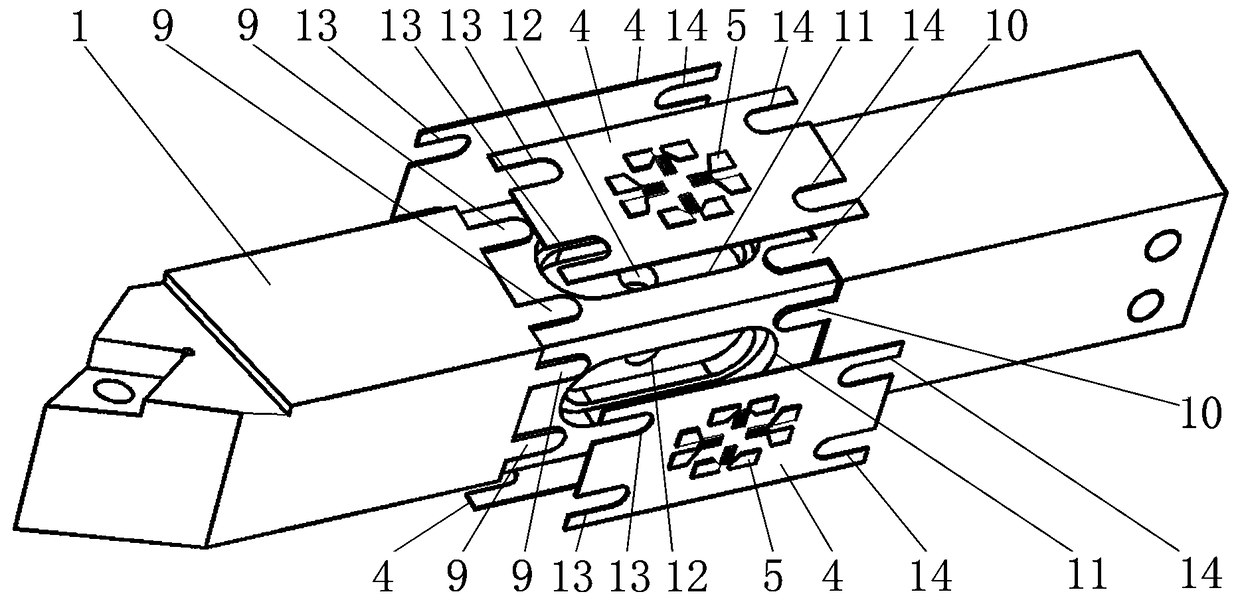

[0016] An integrated turning force measuring tool system embedded with a film sensor, comprising a turning tool holder 1, a turning tool blade 2, a countersunk screw 3, a square elastic substrate 4, a film sensor 5, a Wheatstone bridge module 6, No. II countersunk screw 7, signal processing module 8, PC;

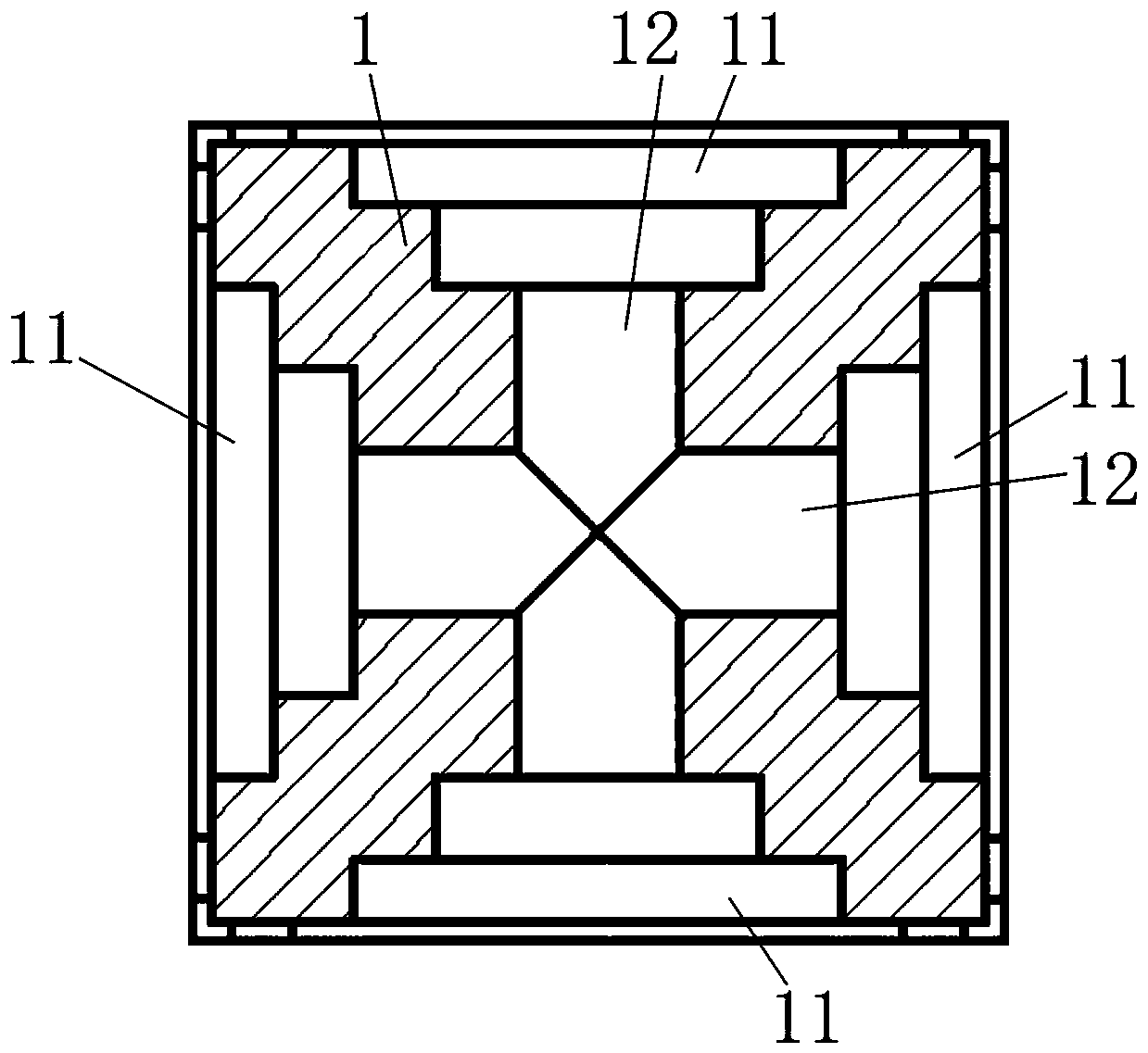

[0017] Wherein, the front end of the upper side of the turning tool holder 1 is provided with an assembly groove, and the groove bottom of the assembly groove is provided with a first threaded concave hole; the left side rear end of the turning tool holder 1 is provided with two second threaded threads Concave hole; the middle part of the four sides of the turning tool holder 1 is respectively provided with a square positioning groove, and the four square positioning grooves are connected as a whole; the front groove wall of each square positioning groove is extended and provided with two mutually Symmetrical front positioning protrusions 9; the rear groove wall of each squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com