Member with thin film sensor and manufacturing method of member

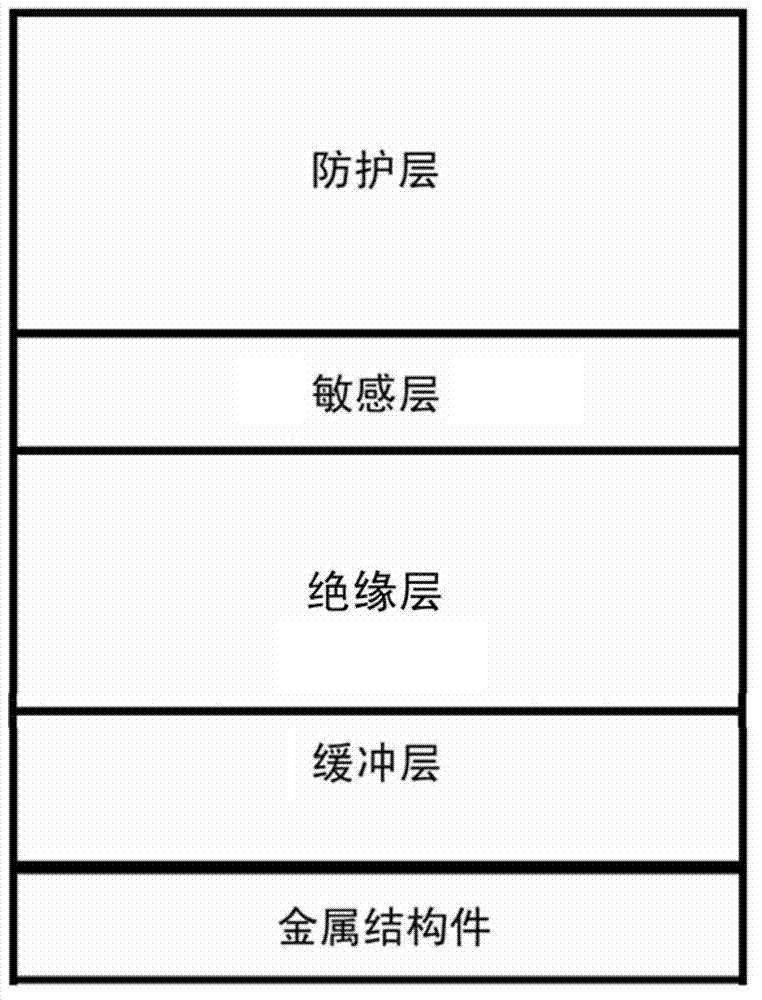

A thin-film sensor and component technology, which is applied in the field of materials and sensing, can solve problems affecting reliability, adhesive layer failure, and inability to monitor, and achieve good adhesion, good stability, and reliable protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

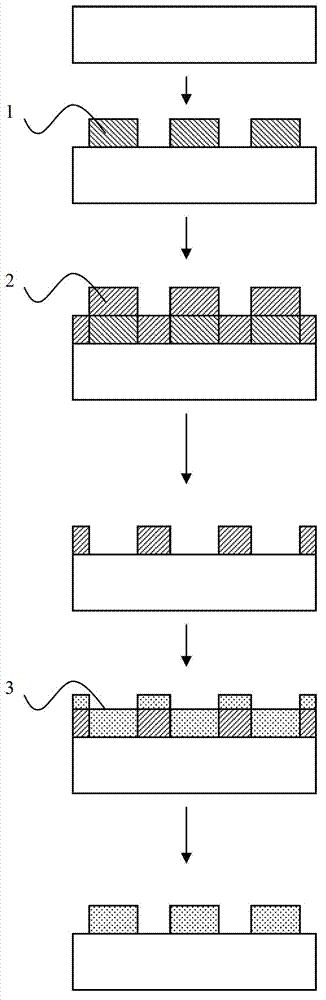

Method used

Image

Examples

Embodiment 1

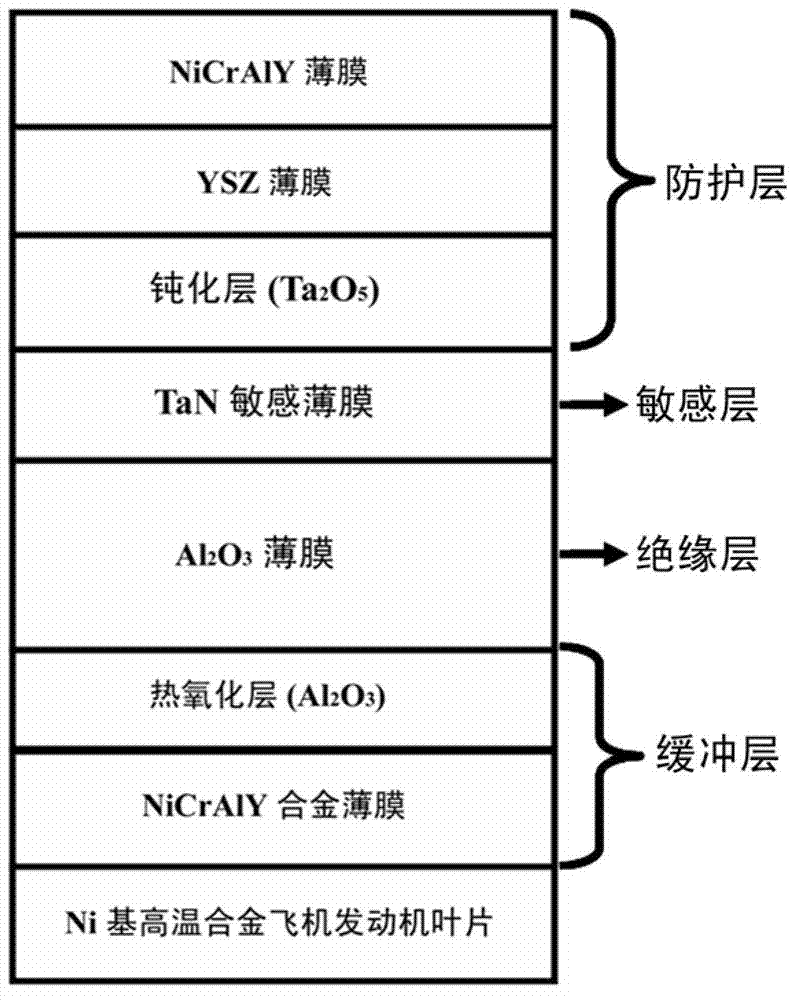

[0058] Embodiment 1: Ni-based superalloy surface film strain gauge

[0059] This embodiment is a Ni-based high-temperature alloy aircraft engine blade component. In this embodiment, the NiCrAlY alloy layer and its thermal oxide layer are used to form a buffer layer, and the Al 2 o 3 The thin film is used as an insulating layer. Since the material properties of the NiCrAlY thin film and the Ni-based superalloy are very close, the adhesion of the NiCrAlY thin film on the surface of the Ni-based superalloy is good. The surface of the film is naturally oxidized to form a layer of Al 2 o 3 thin film, since the thermal oxide layer is oxidized by the NiCrAlY film, the adhesion between the thermal oxide layer and the NiCrAlY film is also very good; electron beam evaporation is used to grow Al 2 o 3 The thin film acts as an insulating layer, since the main component of the thermal oxide layer is Al 2 o 3 , therefore, the insulating layer is actually in the Al 2 o 3 Al deposited...

Embodiment 2

[0061] Example 2: Development of a thin-film pressure sensor on a stainless steel surface

[0062] According to the present invention, an ultra-high-voltage rail pressure sensor for a high-pressure common-rail EFI diesel engine is also produced on a stainless steel substrate. In this embodiment, a NiCrSi alloy layer and its thermal oxidation layer are used to form a buffer layer. 2 The film is used as an insulating layer. Since the properties of the NiCrSi film are very close to the stainless steel substrate, the NiCrSi film has good adhesion on the surface of the stainless steel substrate. After the deposition of the NiCrSi adhesive layer film, it can be naturally oxidized on the surface of the NiCrSi film after high temperature heat treatment. A layer of SiO 2 thin film, since the thermal oxide layer is oxidized by the NiCrSi film, the adhesion between the thermal oxide layer and the NiCrSi film is also very good; electron beam evaporation is used to grow SiO 2 The thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com