Silicon-base piezoelectric film sensor for biological micromass detection and its making process

A piezoelectric film and sensor technology, applied in special data processing applications, instruments, measuring devices, etc., can solve problems such as different resonance electrodes, insufficient sensitivity, and differences in resonance performance, and achieve the effect of increasing resonance frequency and detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: silicon-based piezoelectric thin film biosensor preparation, its steps are

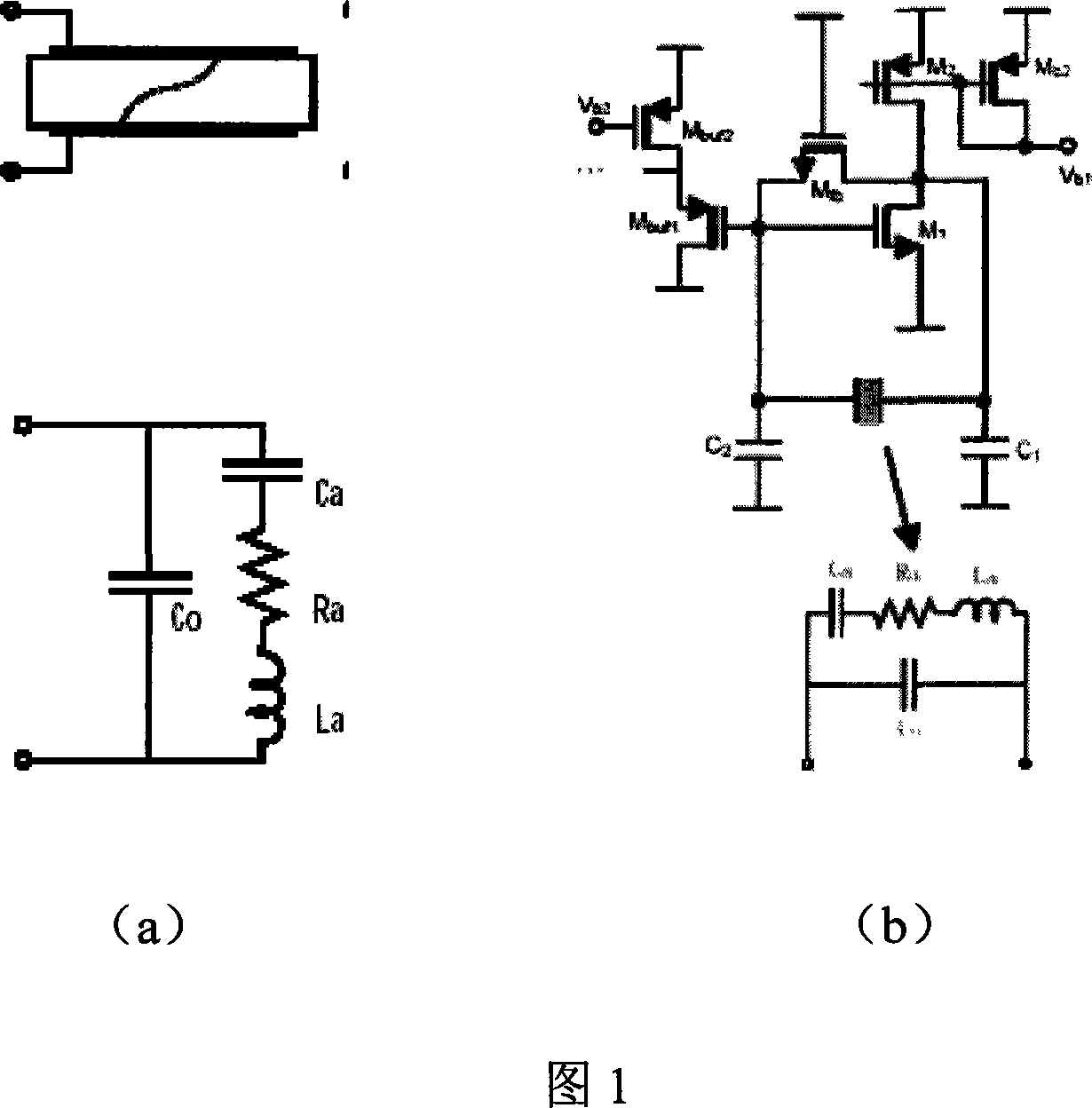

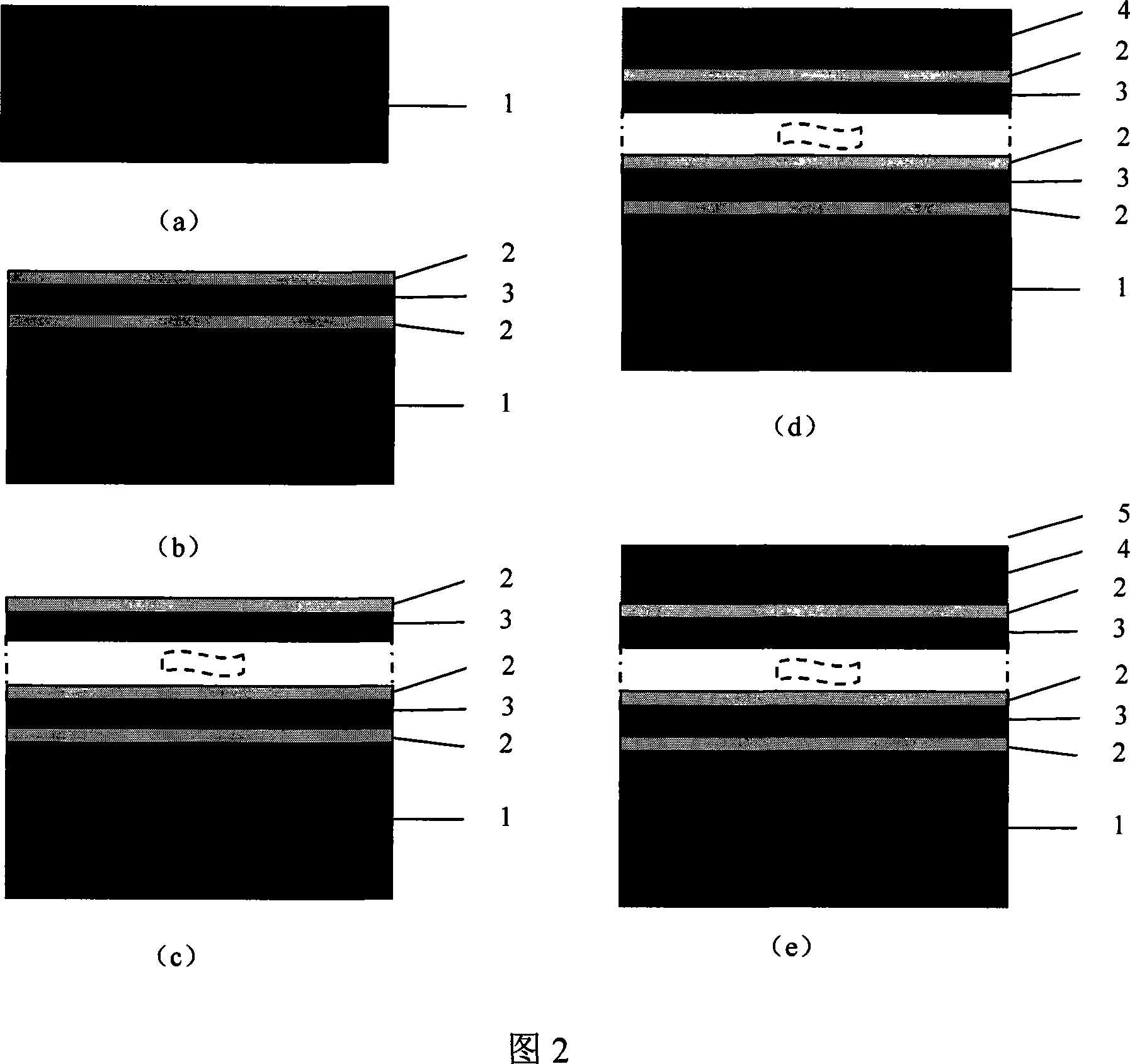

[0051] (1) The prepared piezoelectric resonator with multiple Bragg reflection layers. On a (100) oriented Si wafer with a diameter of 3 inches, a Pt / ZnO Bragg reflective layer was sputtered by multi-target magnetron sputtering. Before starting, evacuate to a background vacuum of 2×10 -4 Pa, and then heat the substrate Si wafer to 300°C. The sputtering power is DC 100W and RF 200W respectively; the sputtering gas flow is argon (Ar) 50sccm and argon (Ar):oxygen (O 2 ), 25:25sccm; the sputtering working pressure is 1.7×10 -1 Pa and 1.8×10 -1 Pa; The Bragg reflective layer was prepared by multi-target continuous sputtering. Each film is hundreds of nanometers thick. [Figure 2(a)~(c)].

[0052] (2) Preparation of the piezoelectric thin film layer: the piezoelectric thin film is prepared on the Bragg reflection layer. Using a multi-target magnetron sputtering apparatus, the pre...

Embodiment 2

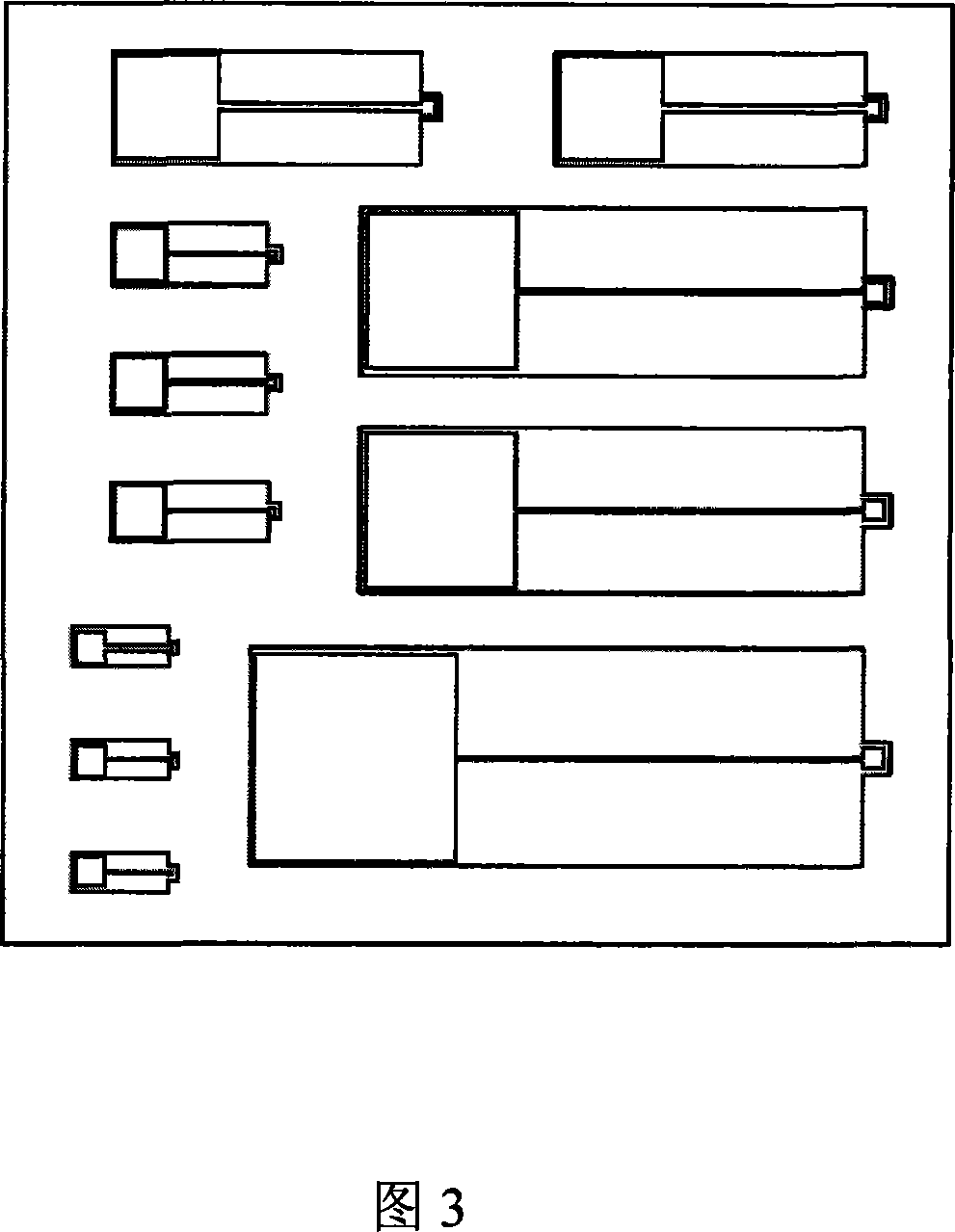

[0060] On the basis of the entire thin film resonator device preparation process described in Example 1, the preparation method of the Bragg layer in the process step (1) is changed: the sputtering gas flow rate of sputtering Pt and ZnO is respectively adjusted to 100 sccm of argon and 50 sccm of oxygen , argon 50sccm, and then improve the sputtering working pressure to be 0.40Pa and 0.37Pa respectively; In the process step (2), the piezoelectric thin film layer is also correspondingly changed to the oxygen and argon flow rate as oxygen 50sccm, argon 50sccm, to improve the sputtering work The air pressure is 0.37Pa. And change the thickness of the film to change the characteristic resonant frequency; in the process step (5), a better graphic electrode structure (Figure 7) is used to prepare a silicon-based piezoelectric thin film biosensor, and more accurately realize the biomolecules after binding. The shift of the resonance peak. (Figure 8)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com