Preparation method of novel cloudy-surface release paper

A release paper, matte technology, applied in chemical instruments and methods, paper/cardboard layered products, coatings, etc. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of preparation method of novel matte release paper

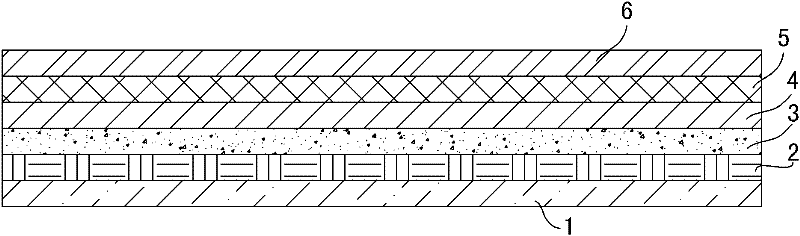

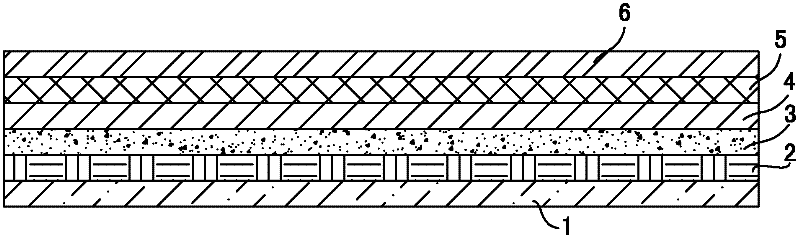

[0030] See attached figure 1 Shown, a kind of preparation method of novel matte release paper, the preparation steps are as follows:

[0031] First of all, the surface of the base paper of the release paper is treated to make the surface free of paper dust and stains.

[0032] (1) On the surface of one side of the release paper base paper, use a laminating machine to coat a layer of PE coating layer 1. After the coating layer 1 cools down, coat the surface of the other side of the release paper base paper Cloth one layer of adhesive layer 3 to obtain the substrate layer, and set aside. The laminating machine can use the high-speed extrusion single-sided casting composite unit type A produced by Changzhou Laiyi Plastic Machinery Co., Ltd.

[0033] (2) Coating a layer of matte coating agent with a thickness of 0.2 to 2 microns on the surface of the polyethylene terephthalate film layer. The formu...

Embodiment 2 5

[0037] Embodiment 2~5: Its preparation method of a kind of matte release paper

[0038] 1, method is the same as embodiment two.

[0039] 2, the related materials that embodiment two~five use are as follows:

[0040] (1) Material of coating layer: Example 3, polyvinyl chloride; Example 4, polyethylene terephthalate; Example 5, polyethylene; Example 6, polypropylene.

[0041] (2) Film layer: Example 3, polypropylene film; Example 4, polyethylene film; Example 5, cast polypropylene film; Example 6, polyethylene terephthalate film.

[0042] 3. See Table 1 for the formula of matte coating agent.

[0043] Table 1

[0044] Embodiment one Embodiment two Embodiment Three Embodiment Four Embodiment five Matte Additive 4% 5% 2% 2.5% 6% Multifunctional Acrylate Monomer 34.5% 30% 43% 45% 44.3% Initiator 0.2% 0.5% 0.7% 1% 0.7% solvent 61.3% 64.5% 54.3% 51.5% 49%

[0045] Note: In Table 1:

[0046] 1. Matte surface additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com