Catalyst for ethylene oligomerization and preparation method thereof

A technology of ethylene oligomerization and catalyst, applied in the field of ethylene oligomerization catalyst and its preparation, to achieve the effects of simplified post-treatment process, high selectivity and avoiding elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

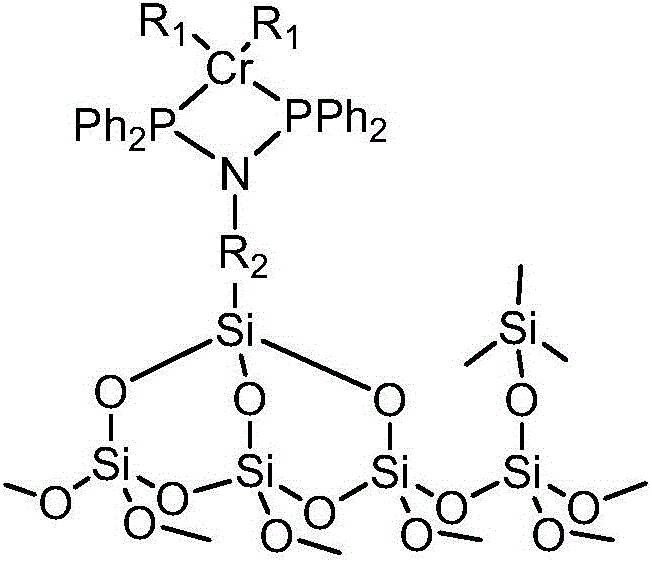

[0031] (1) Synthesis of PNP ligand: take 7.02ml (30.0mmol) aminopropyltriethoxysilane (APTES) and 9.19ml (66.0mmol) triethylamine (NEt 3 ) in a round-bottom bottle with a branched mouth, and protect it with nitrogen, add 120ml of toluene, and stir at -40°C. After stirring evenly, slowly drop diphenyl phosphorus chloride (Ph 2 PCl) 11.14ml (60.0mmol) to room temperature (dropping time 1.5h), after stirring at room temperature for 2h, press filter to obtain the liquid part, and wash the solid three times with a mixed solvent of 20ml toluene and 20ml ether each time. The liquids were collected together, vacuum-dried, and finally recrystallized three times with treated ethanol to obtain the final white powder, which is the desired PNP ligand.

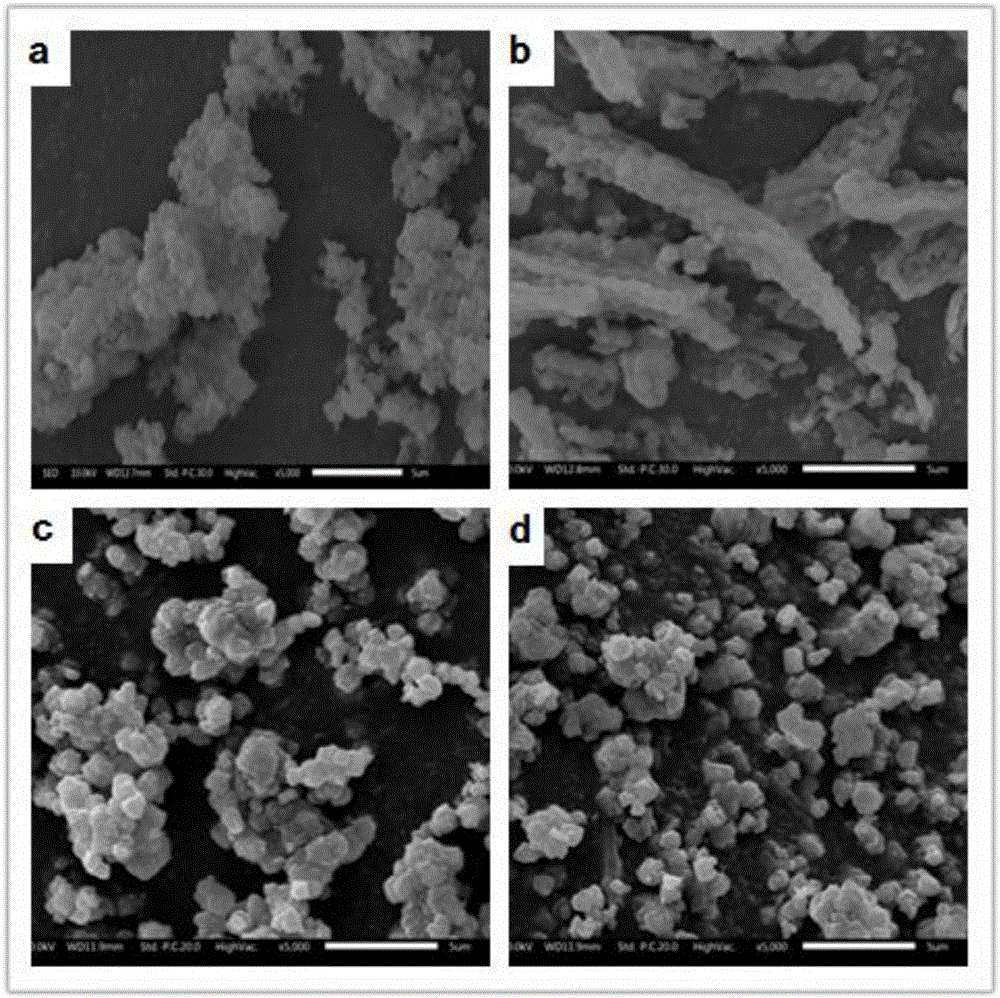

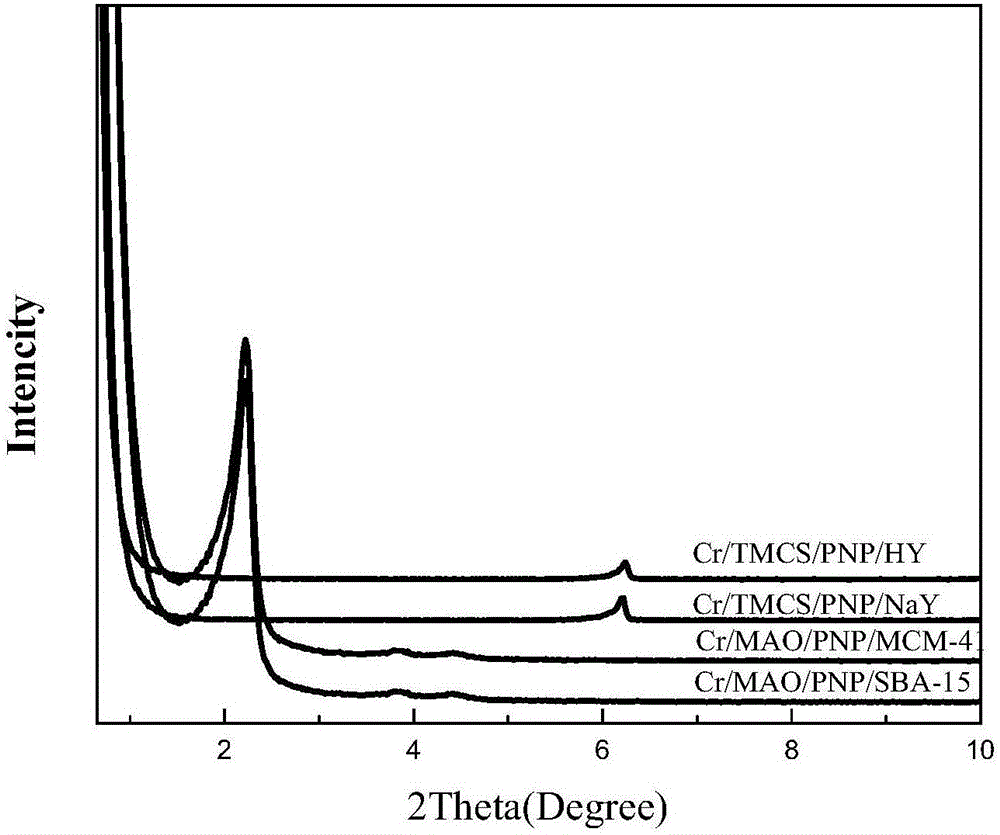

[0032] (2) Grafting of PNP ligands on molecular sieves: Take 5.00 g of mesoporous molecular sieves MCM-41 and 1.00 g of PNP ligands after vacuum drying (100 ° C, -0.1 MPa, 10 h) in a nitrogen-protected reaction flask, add toluene , the mo...

Embodiment 2

[0036] (1) Synthesis of PNP ligand: take 7.02ml (30.0mmol) aminopropyltriethoxysilane (APTES) and 9.19ml (66.0mmol) triethylamine (NEt 3 ) in a round-bottom bottle with a branched mouth, and protect it with nitrogen, add 120ml of toluene, and stir at -40°C. After stirring evenly, slowly drop diphenyl phosphorus chloride (Ph 2 PCl) 11.14ml (60.0mmol) to room temperature (dropping time more than 1h), after stirring at room temperature for 2h, press filter to obtain the liquid part, and wash the solid three times with a mixed solvent of 20ml toluene and 20ml ether each time. The liquids were collected together, vacuum-dried, and finally recrystallized three times with treated ethanol to obtain the final white powder, which is the desired PNP ligand.

[0037] (2) Grafting of PNP ligands on molecular sieves: Take 5.00 g of mesoporous molecular sieve SBA-151.00 g of PNP ligands after vacuum drying (100 ° C, -0.1 MPa, 10 h) in a nitrogen-protected reaction flask, add toluene, toluen...

Embodiment 3

[0041] (1) Synthesis of PNP ligand: take 7.02ml (30.0mmol) aminopropyltriethoxysilane (APTES) and 9.19ml (66.0mmol) triethylamine (NEt 3 ) in a round-bottom bottle with a branched mouth, and protect it with nitrogen, add 120ml of toluene, and stir at -40°C. After stirring evenly, slowly drop diphenyl phosphorus chloride (Ph 2 PCl) 11.14ml (60.0mmol) to room temperature (dropping time more than 1h), after stirring at room temperature for 2h, press filter to obtain the liquid part, and wash the solid three times with a mixed solvent of 20ml toluene and 20ml ether each time. The liquids were collected together, vacuum-dried, and finally recrystallized three times with treated ethanol to obtain the final white powder, which is the desired PNP ligand.

[0042] (2) Grafting of PNP ligands on molecular sieves: take 5.00 g of microporous molecular sieve NaY 1.00 g of PNP ligands after vacuum drying (100 ° C, -0.1 MPa, 10 h) in a nitrogen-protected reaction flask, add toluene, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com