Preparation method of supported carbon nitride photo-catalyst

A supported, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of powder photocatalyst limitation, hindering the process of industrialization, and inability to reuse, and achieve high efficiency and stability. Photocatalytic activity, increasing loading, and effect of increasing loading and reaction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a kind of preparation method of supported carbon nitride photocatalyst, comprises the following steps:

[0053] Mix the carrier and the carbon and nitrogen source in water, and obtain the photocatalyst precursor after impregnation;

[0054] Recrystallizing the photocatalyst precursor after drying to obtain a recrystallized product;

[0055] The recrystallized product is calcined to obtain a supported carbon nitride photocatalyst.

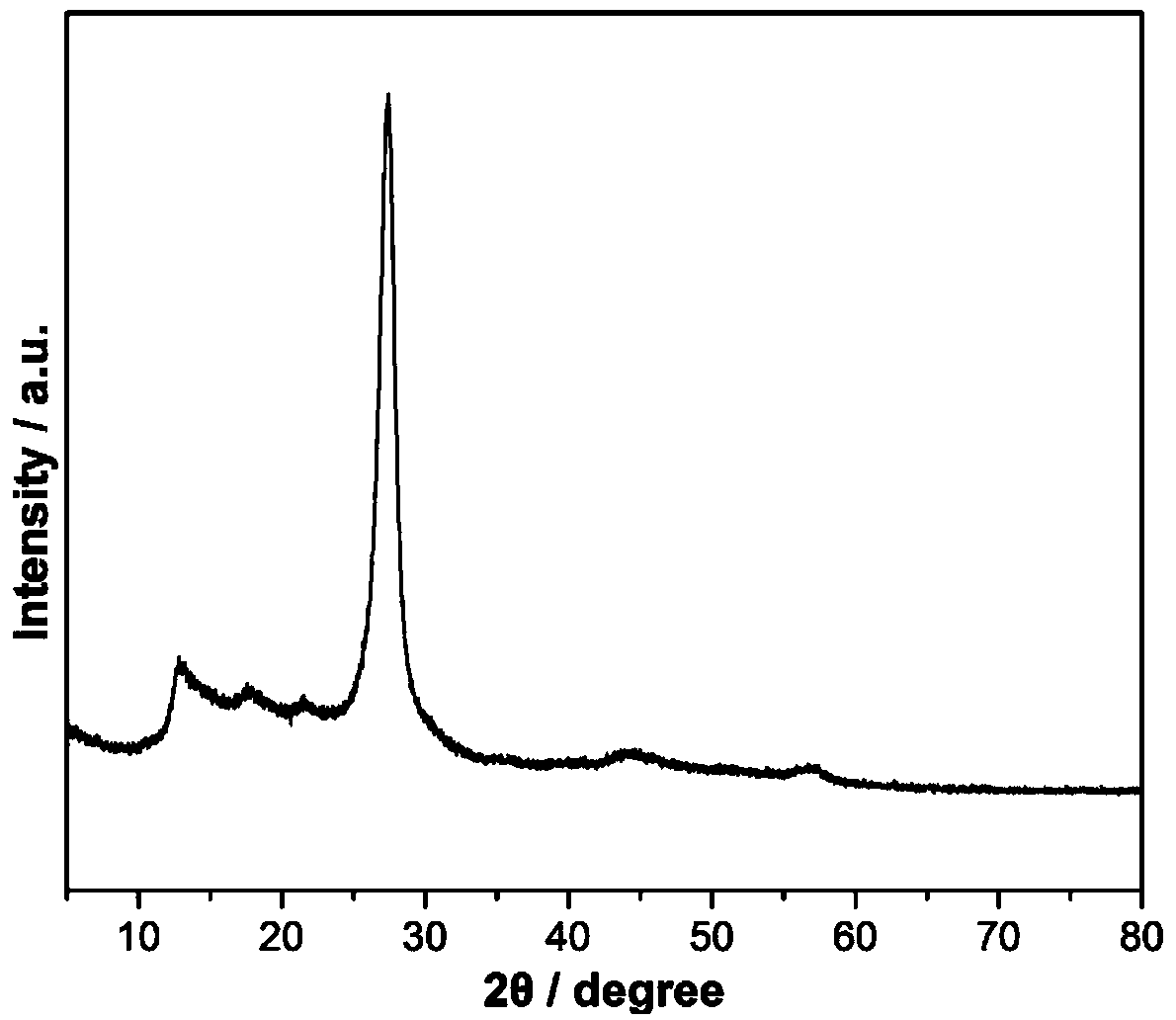

[0056]In the method provided by the invention, the carrier and the carbon nitrogen source are recrystallized in water and then calcined to obtain a loaded carbon nitride photocatalyst. In the loaded carbon nitride photocatalyst obtained by the method provided by the present invention, there is a firmer binding force between the carrier and the carbon nitride, so that the obtained photocatalyst has a more efficient and stable photocatalytic activity, and it is effective against 600ppb levels of NO The removal rate is k...

Embodiment 1

[0088] Rinse 171.235g of alumina foam ceramics with deionized water three times, dry them, and place them in a muffle furnace for pretreatment at 300°C for 1 hour, then cool them down for use. Add 40g of thiourea to 300mL of deionized water, stir with a glass rod for 20 minutes, transfer the pretreated alumina foam ceramics into a large crucible, continue to add water until the liquid level is at least below the surface of the carrier, turn over the carrier several times, at 70 Recrystallized at ℃ for 12h. Cover the crucible containing the sample and put it into a muffle furnace, calcinate at 550°C for 2 hours, cool and recover to obtain supported carbon nitride.

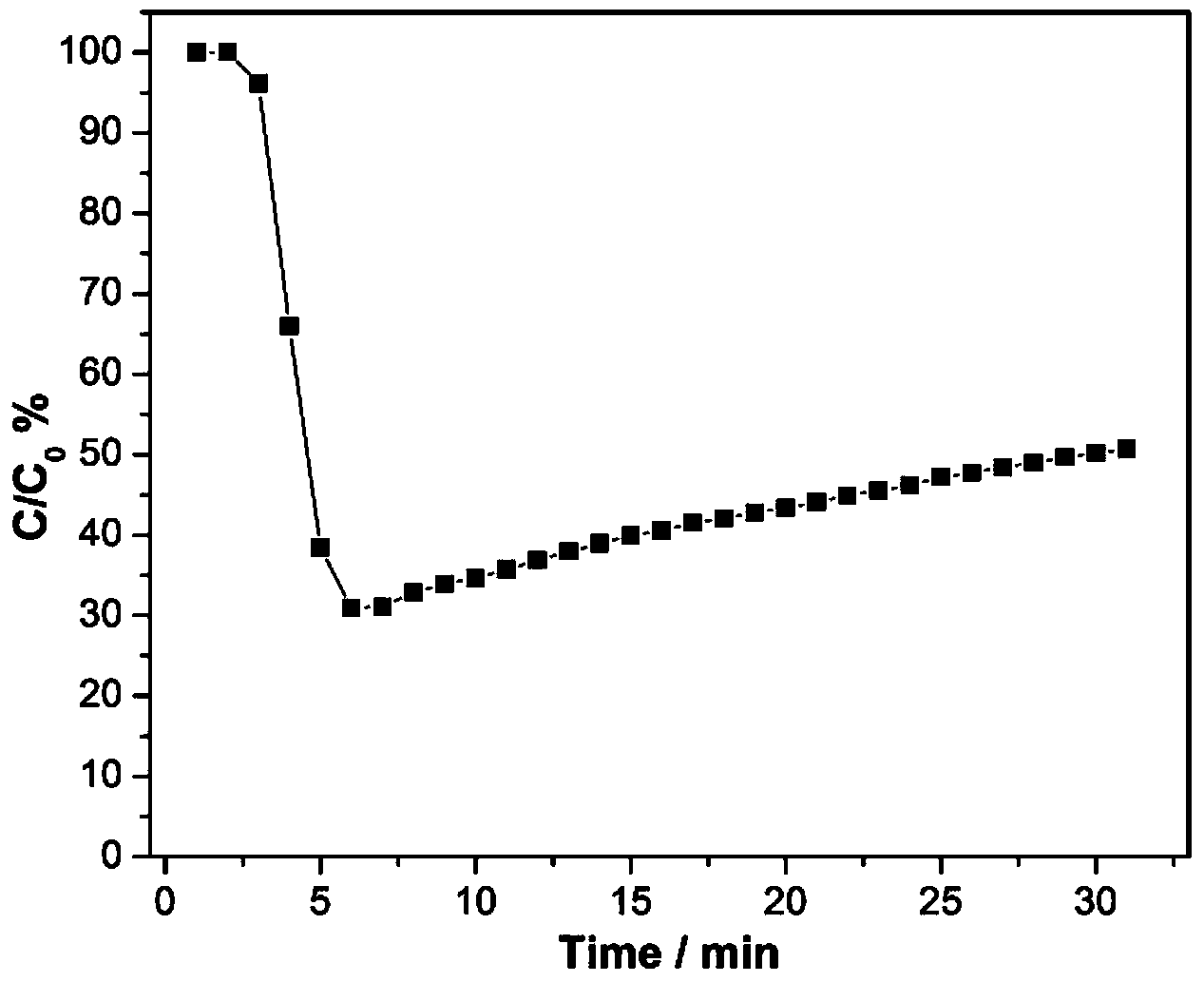

[0089] The present invention studies the photocatalytic activity of the obtained loaded carbon nitride, and the specific process is as follows: in an environment where the relative humidity is 60% and the oxygen content is 21%, the obtained loaded carbon nitride is placed in the NO flow, The initial concentration o...

Embodiment 2

[0091] Rinse 170.768g of alumina foam ceramics with deionized water three times, dry them, and place them in a muffle furnace for pretreatment at 300°C for 1 hour, then cool them down for use. Add 40g of dicyandiamide to 300mL of deionized water, stir with a glass rod for 20 minutes, transfer the pretreated alumina foam ceramics into a large crucible, continue to add water until the liquid level is at least above the surface of the carrier, turn over the carrier several times, Recrystallize at 70°C for 12h. Cover the crucible containing the sample and put it into a muffle furnace, calcinate at 550°C for 2 hours, cool and recover to obtain supported carbon nitride.

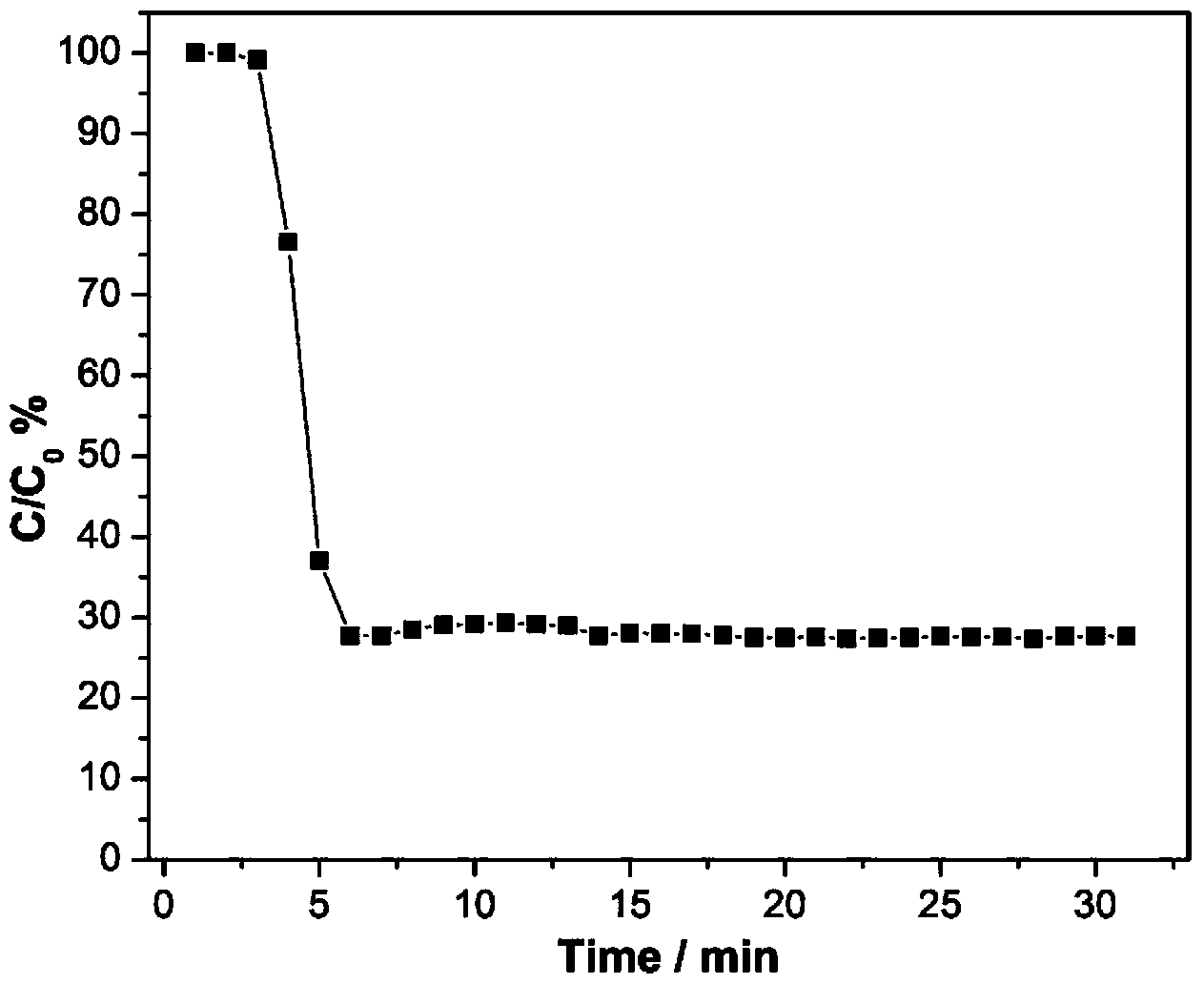

[0092] The present invention adopts the test scheme of photocatalytic activity in embodiment 1, the photocatalytic activity of the supported carbon nitride obtained in this embodiment is tested, and the result is as follows figure 2 and as shown in Table 1, figure 2 For the NO removal rate figure of the loaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com