Flexible nanofiber-based electronic skin as well as preparation method

A nanofiber and electronic skin technology, applied in the field of flexible sensors, can solve the problems of low sensitivity, high power consumption, and high working voltage, and achieve high sensitivity, good biocompatibility, and solve the effects of high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a flexible nanofiber-based electronic skin, comprising the following steps:

[0025] 1) Preparation of nanofiber suspension: use a mixed solvent of isopropanol and water with a mass ratio of 6:4 to shear EVOH nanofibers at a speed of 5000r / min for 50s to form a suspension with a solid content of 1% (mass), An EVOH nanofiber suspension was obtained.

[0026] 2) Conduction treatment of the nanofiber suspension: take 50 g of the prepared EVOH nanofiber suspension and place it in an ice bath, add 0.3 g of pyrrole monomer and auxiliary agent anthraquinone-2,7-sulfonic acid sodium salt 0.25 g to it , and then slowly added 4.2 g of 9-hydrated ferric nitrate and 2.7 g of 5-sulfosalicylic acid to react for 4 h. After the reaction is completed, the conductive nanofiber suspension is obtained for use.

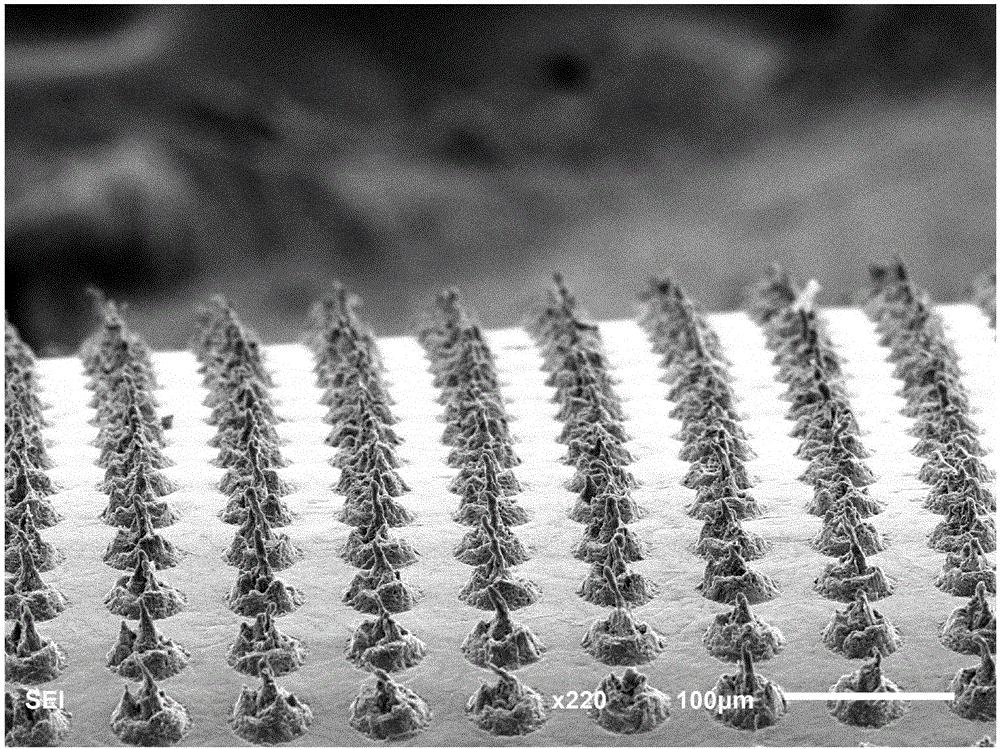

[0027] 3) Template preparation: laser lithography is used to prepare a mold with grooves or micro-protrusion structures;

[0028] 4) Preparation of micro-...

Embodiment 2

[0031] A method for preparing a flexible nanofiber-based electronic skin, comprising the following steps:

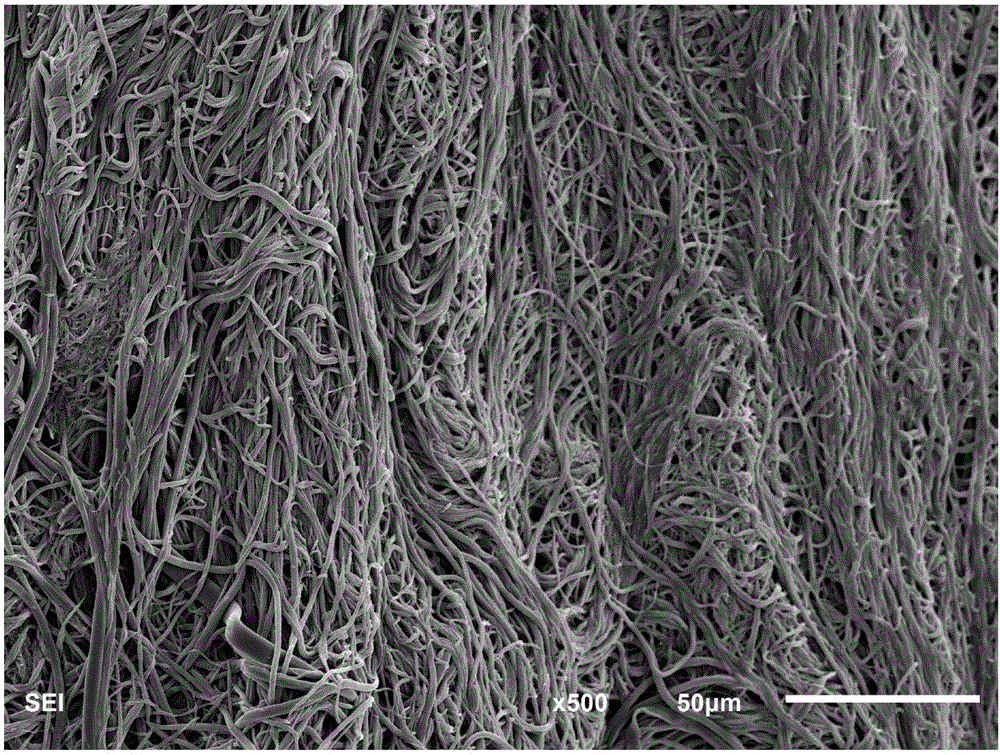

[0032] 1) Preparation of nanofiber suspension: Use a mixed solvent of n-hexane and acetone with a volume ratio of 7:3 to shear POE nanofibers at a speed of 7000r / min for 50s to form a suspension with a solid content of 1% (mass), Obtain POE nanofiber suspension (see figure 1 shown).

[0033] 2) Conduction treatment of the nanofiber suspension: take 50 g of the prepared POE nanofiber suspension and place it in an ice bath, add 0.3 g of pyrrole monomer and auxiliary agent anthraquinone-2-sulfonic acid sodium salt 0.25 g, and then Then slowly add 4.2 g of ferric chloride and 2.7 g of 5-sulfosalicylic acid to react for 4 h. After the reaction is completed, the conductive nanofiber suspension is obtained for use.

[0034] 3) Template preparation: laser lithography is used to prepare a mold with grooves or micro-protrusion structures;

[0035] 4) Preparation of micro-groov...

Embodiment 3

[0038] A method for preparing a flexible nanofiber-based electronic skin, comprising the following steps:

[0039]1) Preparation of nanofiber suspension: use a mixed solvent of isopropanol and water with a mass ratio of 6:4 to shear EVOH nanofibers at a speed of 4000r / min for 50s to form a suspension with a solid content of 1% (mass), An EVOH nanofiber suspension was obtained.

[0040] 2) Conduction treatment of the nanofiber suspension: take 50 g of the prepared EVOH nanofiber suspension and place it in an ice bath, add 0.3 g of pyrrole monomer and auxiliary agent anthraquinone-2-sulfonic acid sodium salt 0.25 g, and then Then slowly add 4.2 g of ferric chloride and 2.7 g of 5-sulfosalicylic acid to react for 4 h. After the reaction is completed, the obtained conductive nanofiber suspension is mixed with the POE nanofiber suspension for use.

[0041] 3) Template preparation: laser lithography is used to prepare a mold with grooves or micro-protrusion structures;

[0042] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com