Eight-arm polyethylene glycol, preparation method and functionalized derivative thereof, and biologically relevant substance modified with functionalized derivative

A polyethylene glycol and functionalization technology, applied in the field of preparation of eight-arm polyethylene glycol, functionalized derivatives and modified biological-related substances, can solve the problem of the number of difficult monomer units, the low purity of the target product, and the molecular weight distribution. It can reduce the production cost, control the molecular weight and its distribution accurately, and reduce the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

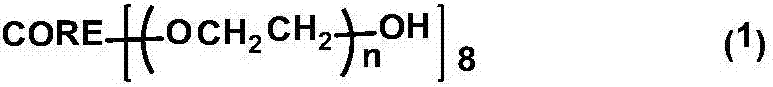

[0085] 2. a preparation method of eight-arm polyethylene glycol, comprising the following steps:

[0086] Step 1. Use small molecule CORE(OH) containing octahydroxyl 8 Initiator system; Octahydroxyl small molecule is used as initiator, and base forms co-initiator system; Described octahydroxyl small molecule is preferably octahydroxyl disaccharide small molecule;

[0087] Step 2, initiate ethylene oxide polymerization;

[0088] Step 3. After the reaction is completed, add a proton source to the intermediate product system having eight polyethylene glycol chains obtained in step 2 to obtain the hydroxyl-terminated eight-armed polyethylene glycol.

[0089] The above steps can be carried out in a solvent or without a solvent, and the solvent is not particularly limited, but preferably an aprotic solvent, such as toluene, benzene, xylene, acetonitrile, ethyl acetate, tetrahydrofuran, chloroform, dichloromethane, dimethyl Sulfoxide, dimethylformamide or dimethylacetamide, more pr...

Embodiment 1

[0927] Example 1: Preparation of eight-arm polyethylene glycol H1-1 with sucrose center structure

[0928] The total molecular weight is designed to be about 20kDa, wherein the molecular weight of each PEG chain is about 2500Da, corresponding to n≈56. The eight-valent central structure CORE is the residue after deoctahydroxylation of sucrose.

[0929] a. Add dimethyl sulfoxide (3L), sucrose (150mmol) and diphenylmethyl potassium (60mmol) sequentially into an anhydrous and oxygen-free airtight reaction kettle; wherein, the hydroxyl value of the sucrose raw material is determined by the phthalic anhydride-pyridine method Carry out measurement confirmation;

[0930] b. adding calculated amount of ethylene oxide (3Kg), gradually warming up to a temperature of 60°C, and reacting for 72 hours;

[0931] c. Add excess water (300mmol) to terminate the reaction, the reaction temperature is 60°C, and the reaction time is 10 minutes;

[0932] d. Open the reaction kettle, concentrate th...

Embodiment 2

[0938] Example 2: Preparation of eight-arm polyethylene glycol H1-2 with maltose center structure

[0939] The total molecular weight is designed to be about 40kDa, wherein the molecular weight of each PEG chain is about 5000Da, corresponding to n≈113. The octavalent central structure CORE is the residue after deoctahydroxylation of maltose.

[0940] a. Add toluene (3L), maltose (150mmol) and potassium tert-butoxide (120mmol) sequentially into an anhydrous and oxygen-free closed reaction kettle; wherein, the hydroxyl value of the maltose raw material is determined and confirmed by the phthalic anhydride-pyridine method;

[0941] b. Add the calculated amount of ethylene oxide (6Kg), gradually heat up to 70°C, and react for 72 hours;

[0942] c. adding excess acetic acid (240mmol) to terminate the reaction, the reaction temperature was 60°C, and the reaction time was 20 minutes;

[0943] d. Open the reaction kettle, concentrate the solvent, refine the product with isopropanol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum tolerated dose | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com