Lead-acid battery capacity restorer

A lead-acid battery, capacity recovery technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of lead-acid battery capacity reduction, active material reduction, etc. The effect of electrical function and stable capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

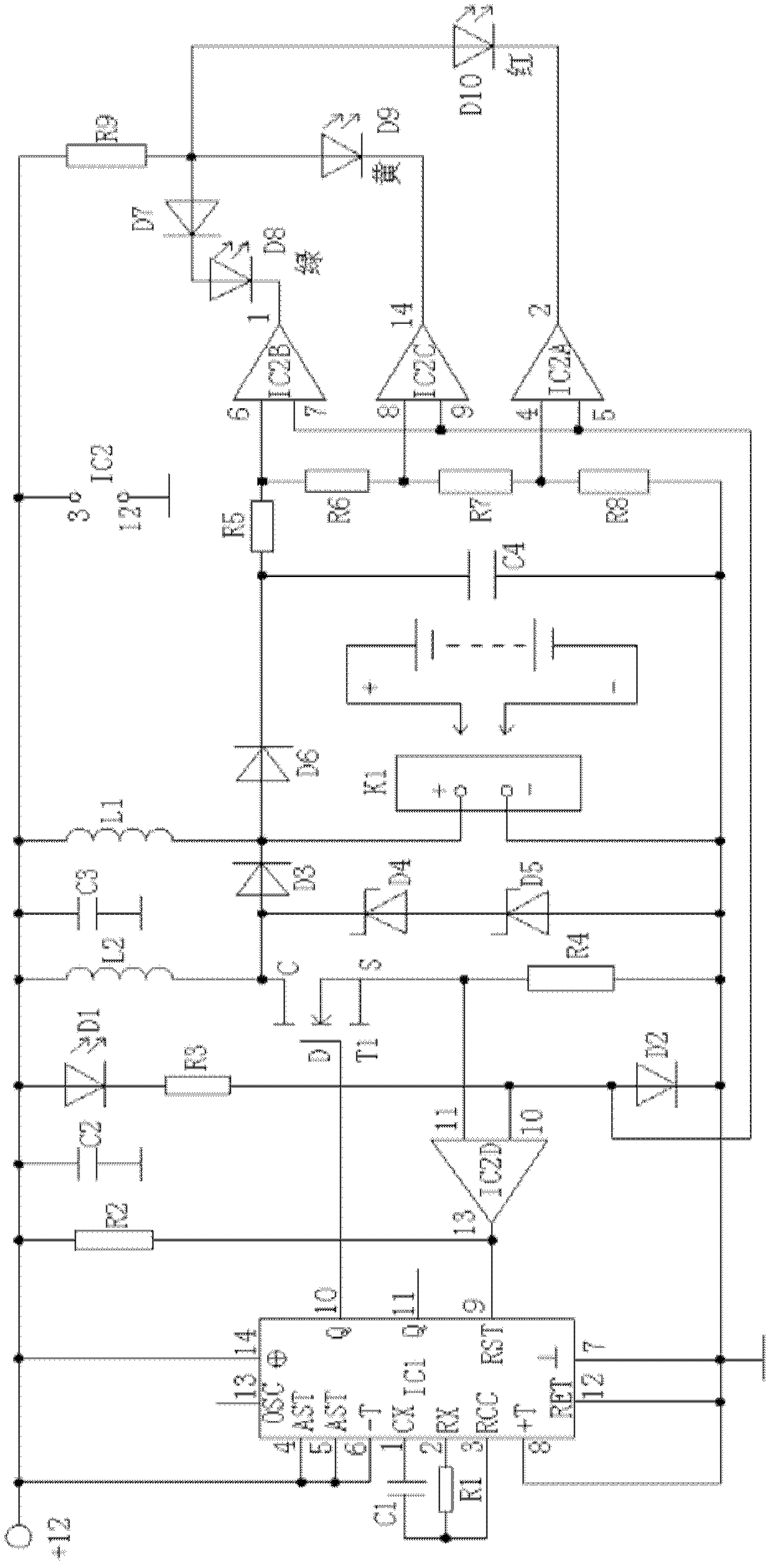

[0015] Such as figure 1 As shown, the present invention includes integrated chip IC1, field effect transistor T1, comparator IC2A, IC2B, IC2C, IC2D, connection terminal K1 and the parallel connection terminal IC2 of this lead-acid battery capacity restorer, the positive and negative poles of connection terminal K1 Connect the positive and negative poles of the lead-acid battery respectively. The positive pole of the terminal K1 is connected to the inductor L1, the negative pole of the terminal K1 is connected to the common ground, one end of the capacitor C3 is connected to the inductor L1 on the positive pole of the terminal K1, and the other end of the capacitor C3 is connected to the ground. The 3rd pin of the access terminal IC2 is connected to the inductance L1 on the positive pole of the terminal K1, and the 12th pin of the access terminal IC2 is connected in parallel to the ground;

[0016] The 4, 5, 6, and 14 pins of the integrated chip IC1 are connected in parallel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com