Rod-shaped nano iron oxide electrode material, and preparation method and application thereof

A nano iron oxide, electrode material technology, applied in iron oxide, iron oxide/iron hydroxide, battery electrodes, etc., can solve the problems of high energy consumption, contain other impurities, low material purity, etc., and achieve easy large-scale industrialization The effect of uniform production, size comparison, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of rod-shaped nano-iron oxide powder:

[0044] Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 0.972g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 0.01485g (the molar ratio of ferric chloride hexahydrate to ammonium dihydrogen phosphate is 26:1) and 160g of deionized water, all of which are put into the hydrothermal reaction kettle, and the hydrothermal reaction time is 2h under the condition of 220°C , and then cooled naturally to room temperature. The precipitate was then washed three times with deionized water and twice with ethanol. After separation, the rod-shaped nano-iron oxide powder was obtained, and the HPLC detection purity was 99.9%.

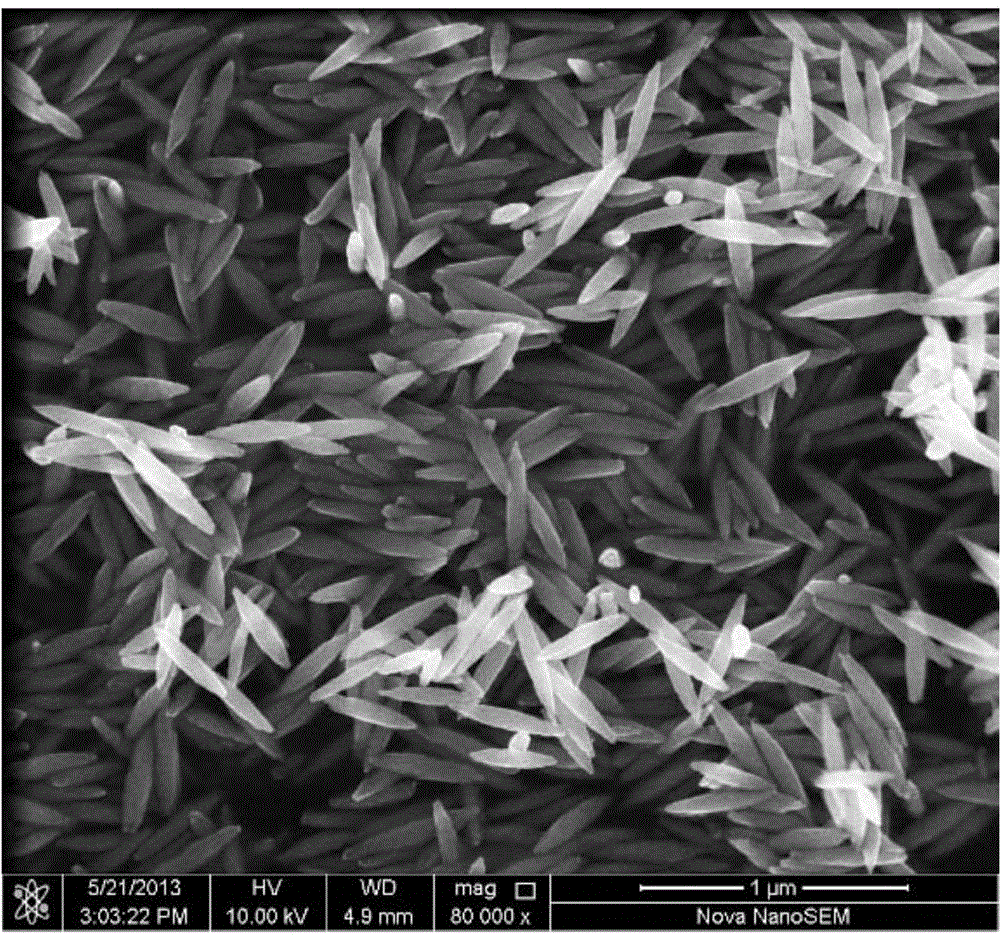

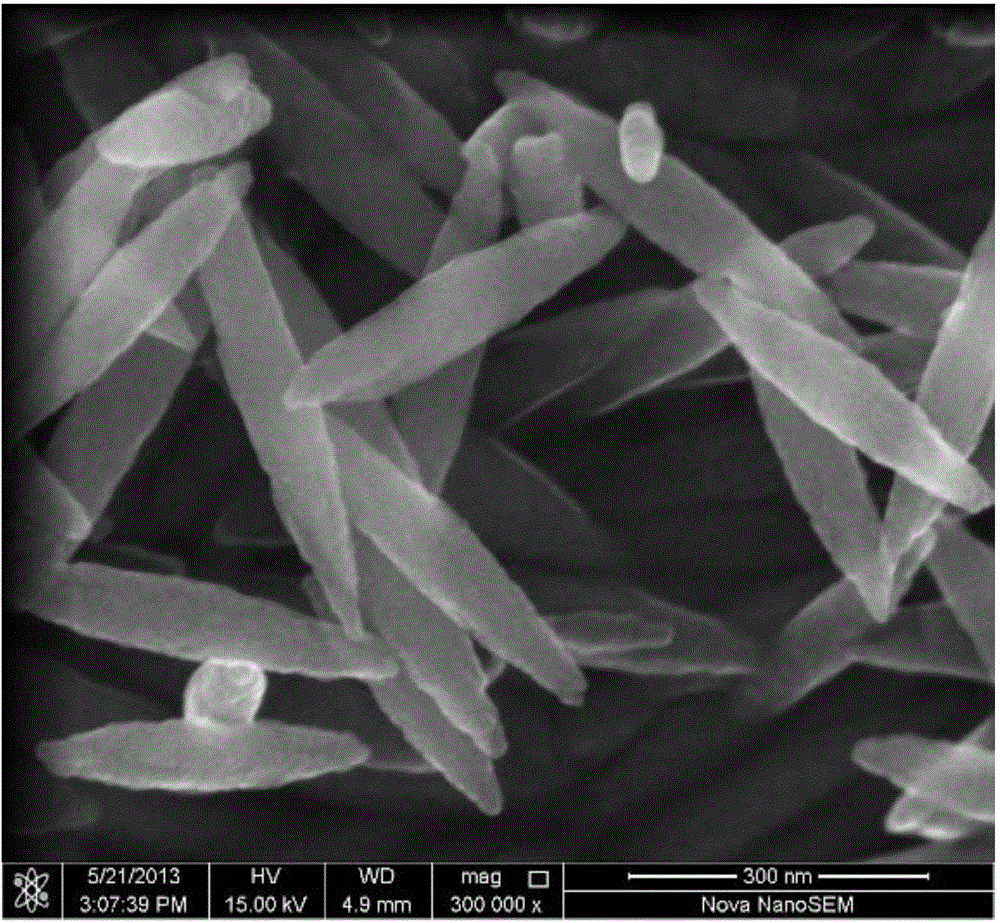

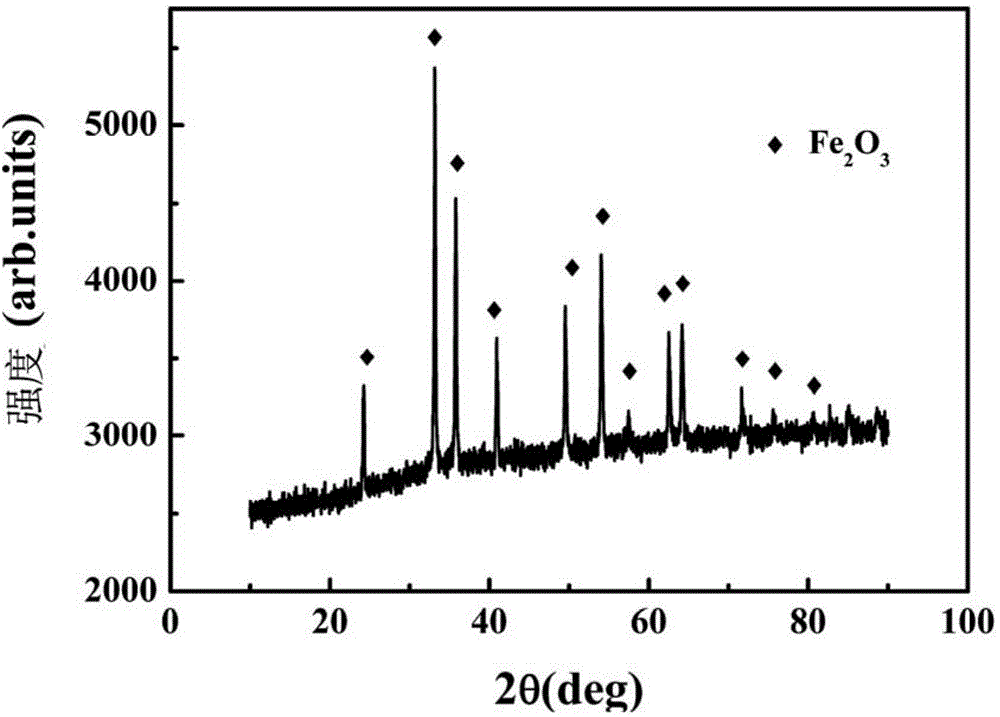

[0045] From figure 1 and figure 2 It can be seen from the figure that the obtained nanomaterials are uniform in size and rod-shaped, with an average diameter of about 60-80 nanometers and a length of about 250-300 nanometers. From image 3 and Figure 4 It can be confirmed that the product is α-Fe ...

Embodiment 2

[0051] Preparation of rod-shaped nano-iron oxide powder:

[0052] Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 0.695g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 0.01g (the molar ratio of ferric chloride hexahydrate to ammonium dihydrogen phosphate is 30:1) and 120g of deionized water, all of which are put into the hydrothermal reaction kettle, and the hydrothermal reaction time is 2h under the condition of 220°C , and then cooled naturally to room temperature. The precipitate was then washed three times with deionized water and twice with ethanol. After separation, the rod-shaped nano-iron oxide powder was obtained, and the HPLC detection purity was 99.9%.

[0053] According to low-magnification SEM analysis, the obtained nanomaterials are uniform in size and rod-shaped, with a diameter of about 60-80 nanometers and a length of about 250-300 nanometers. The XRD analysis can confirm that the product is α-Fe 2 o 3 Phase, obvious α-Fe can be observed at 33゜, 35...

Embodiment 3

[0058] Preparation of rod-shaped nano-iron oxide powder: Except that the hydrothermal reaction condition is 205° C. and the reaction time is 8 h, the preparation method of the rod-shaped nano-iron oxide powder in Example 1 is the same.

[0059] According to low-magnification SEM analysis, the obtained nanomaterials are uniform in size and rod-shaped, with a diameter of about 60-80 nanometers and a length of about 250-300 nanometers. The XRD analysis can confirm that the product is α-Fe 2 o 3 Phase, obvious α-Fe can be observed at 33.1゜, 35.6゜, 53.8゜ 2 o 3 Characteristic peaks.

[0060] Preparation of battery positive and negative electrode sheets with the above-mentioned electrode active materials: same as in Example 1.

[0061] The negative electrode sheet prepared in this example, the lithium sheet as the positive electrode sheet, PE (polyethylene) as the diaphragm, LiPF 6 1mol / l DMC:EC:EMC=1:1:1 is the electrolyte to assemble the button battery 3-A. Constant current c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com