Alloy negative electrode for lithium battery and process for production thereof, and lithium battery

A technology of alloy negative electrode and manufacturing method, which is applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of difficult industrialized mass production, deterioration of discharge capacity, and fragility of Li-Al alloys, and achieve full cycle life and capacity. High density and excellent charge-discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0074] A. Alloy negative electrode for lithium battery

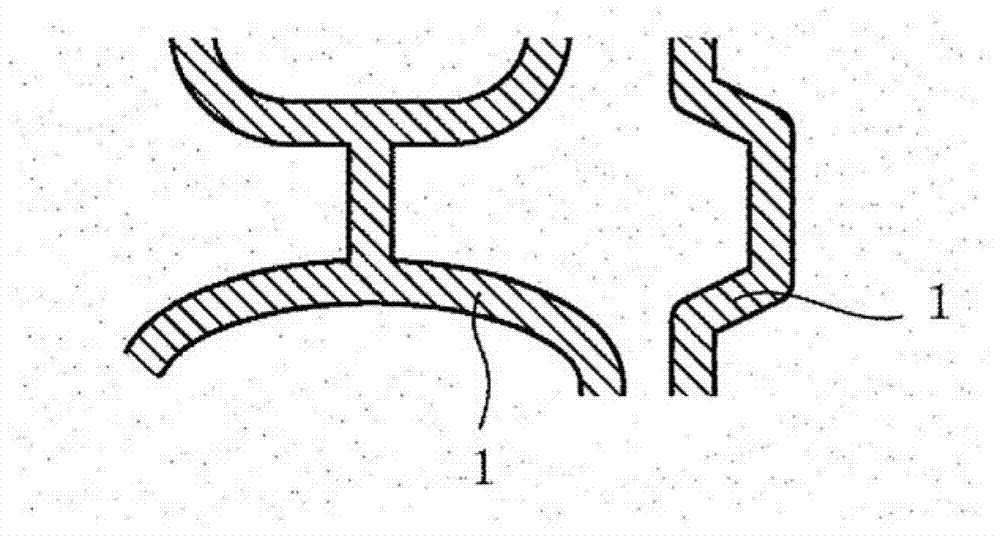

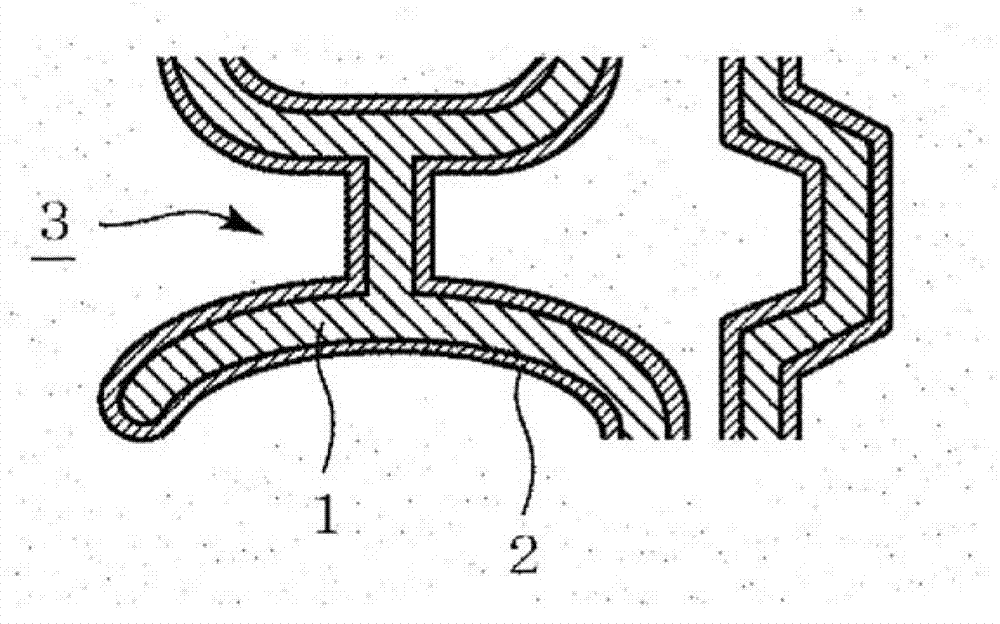

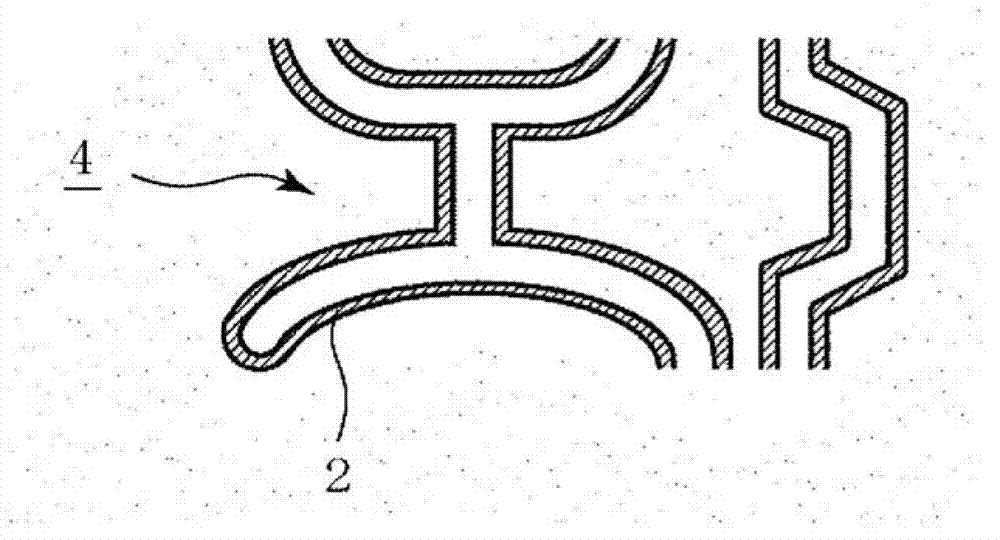

[0075] In the alloy negative electrode for a lithium battery in the present embodiment, the aluminum porous body is filled with lithium metal, and the skeleton of the aluminum porous body is formed of aluminum. And, the alloy negative electrode for lithium battery in the present embodiment is manufactured by the following manufacturing method (refer to Figure 1A~Figure 1C ).

[0076] B. Manufacturing method of alloy negative electrode for lithium battery

[0077] The porous resin 1 can use a foamed resin or non-woven fabric with interconnected pores, particularly preferably a resin with a porosity of 80% to 98% and a pore diameter of about 50 μm to 500 μm, preferably foamed polyurethane.

[0078] Hereinafter, a method for manufacturing an alloy negative electrode for a lithium battery will be described in the order of the aluminum layer forming step, the aluminum porous body manufacturing step, and the lithium metal i...

Embodiment approach 2

[0091] In Embodiment 2, the skeleton of the aluminum porous body is an aluminum coating material in which an aluminum layer is formed on the surface of the core material. In addition, the core material is made of any one of copper, nickel, and iron, and is formed by coating carbon powder on the surface of a resin having through holes, conducts conductive treatment, and then performs plating with a predetermined thickness.

[0092] In Embodiment 2, an alloy negative electrode for a lithium battery and a lithium battery are produced in the same manner as in Embodiment 1, except that the skeleton of the aluminum porous body is an aluminum coating material.

Embodiment approach 3

[0094] In each of the above-mentioned embodiments, the incorporation of lithium metal is not limited to penetration into the pores of the aluminum porous body, and may be formed on the surface of the aluminum porous body.

[0095] In addition, lithium metal does not have to be a single substance, and may be an alloy with other metals, and Li-Si (silicon) and Li-Sn (tin) are particularly suitable as an alloy negative electrode.

[0096] In the case of forming such a Li-Si or Li-Sn alloy negative electrode on an aluminum porous body, an alloy layer of Li and Si or Sn may be formed on the surface of the aluminum porous body, or an alloy layer of Li and Si or Sn may be formed on the "aluminum skeleton" or "formed on An aluminum layer on the surface of a core material such as copper" is formed by providing a Si or Sn metal layer, and further laminating a Li metal layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com