Self-walking clamp and maintenance-free assembling line

A fixture and component technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of consuming manpower and material resources for maintenance, moving parts easily broken, and low economic benefits, achieving good economic benefits and reducing maintenance costs. , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

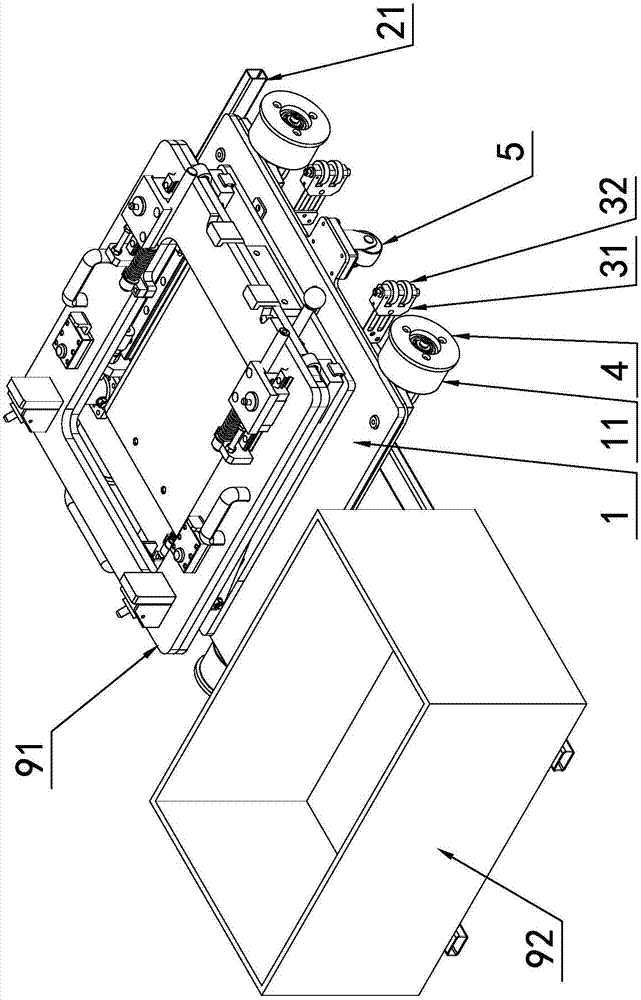

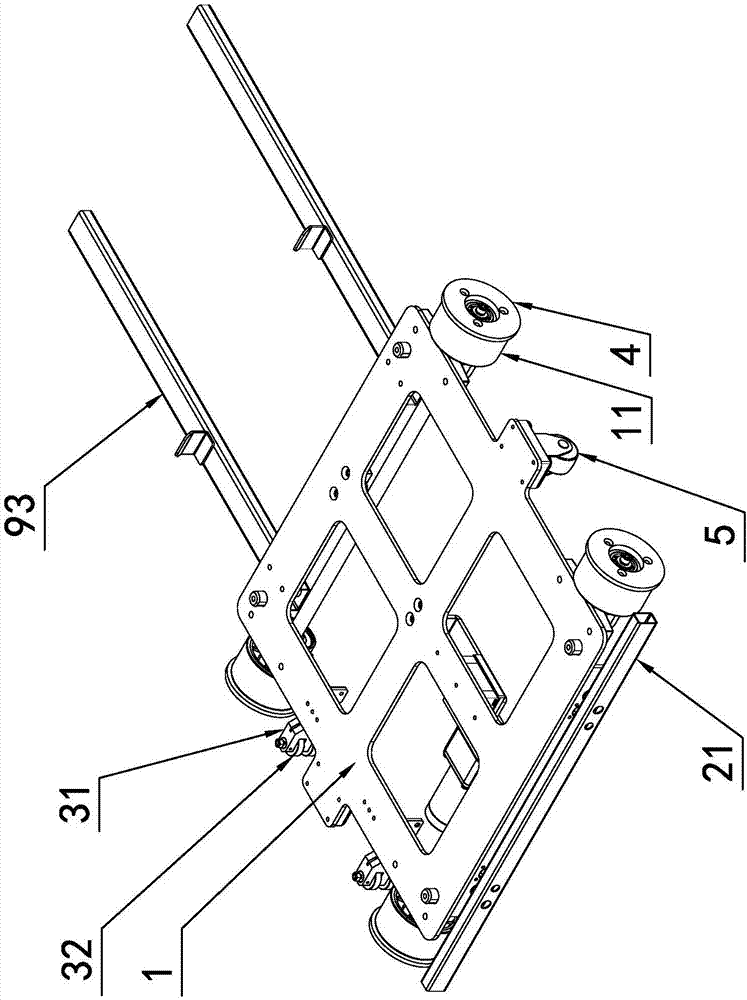

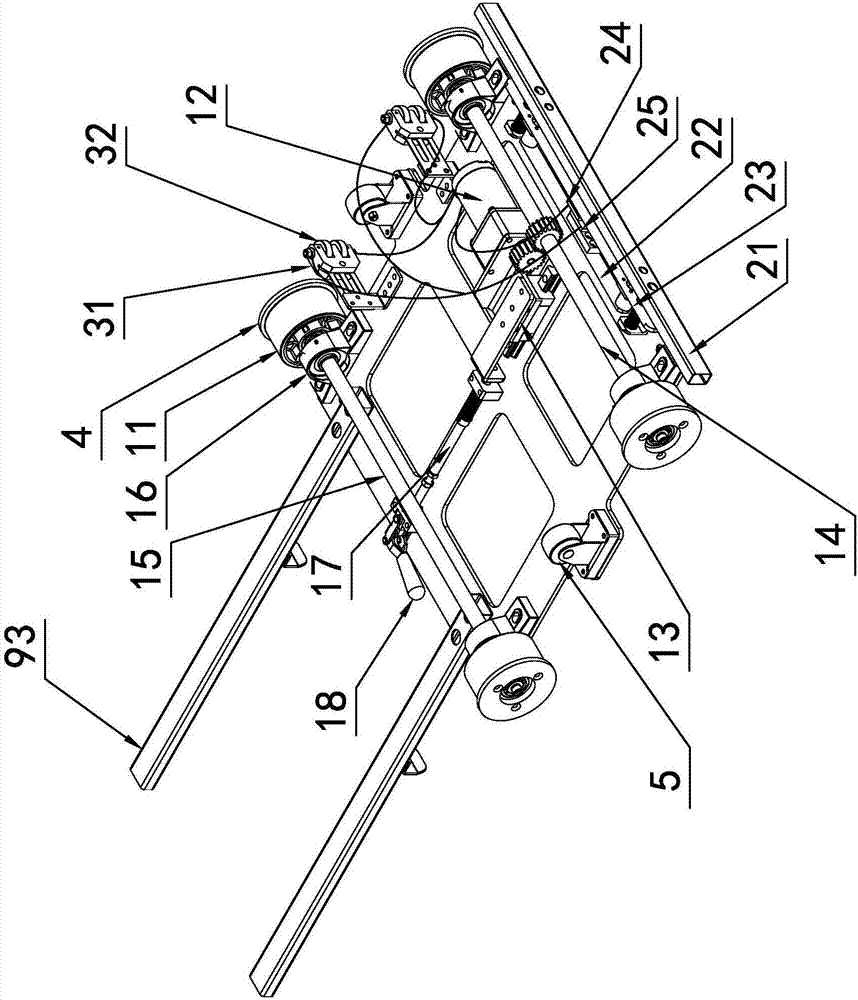

[0027] refer to Figure 1 to Figure 7 , specifically refer to image 3 And take the lower right side as the front end and the upper left side as the rear end.

[0028] The present invention is a self-propelled clamp, including a base plate 1 and a walking assembly arranged on the bottom side of the base plate 1. The walking assembly includes a plurality of casters 11 and a motor 12 for pulling each caster 11 to roll. The circumferential surface of each caster 11 is provided with a polyurethane coating. The bottom plate 1 is provided with a number of conductive modules that transmit electric energy to the motor 12. Each conductive module is installed on the same side of the bottom plate 1. Each group of conductive modules includes two conductive rollers 32 at different heights and the second conductive roller 32 supporting the two conductive rollers. A bracket 31 , the first bracket 31 is installed on the bottom plate 1 , a conductive roller 32 is connected to the live wire en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com