Three-dimensional miniature super capacitor electrode manufactured from nano porous composite material and manufacturing method thereof

A supercapacitor electrode and composite material technology, which is applied in the direction of capacitor electrodes and capacitor parts, can solve the problems of low volume density of electrode materials, low energy storage per unit volume, incompatible manufacturing process, etc., and achieve good charge and discharge cycles performance, high charge and discharge efficiency, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Aiming at the problem that the electrode of the micro-supercapacitor is difficult to form a three-dimensional structure with a high aspect ratio, the invention designs and realizes a three-dimensional forming method of the electrode material.

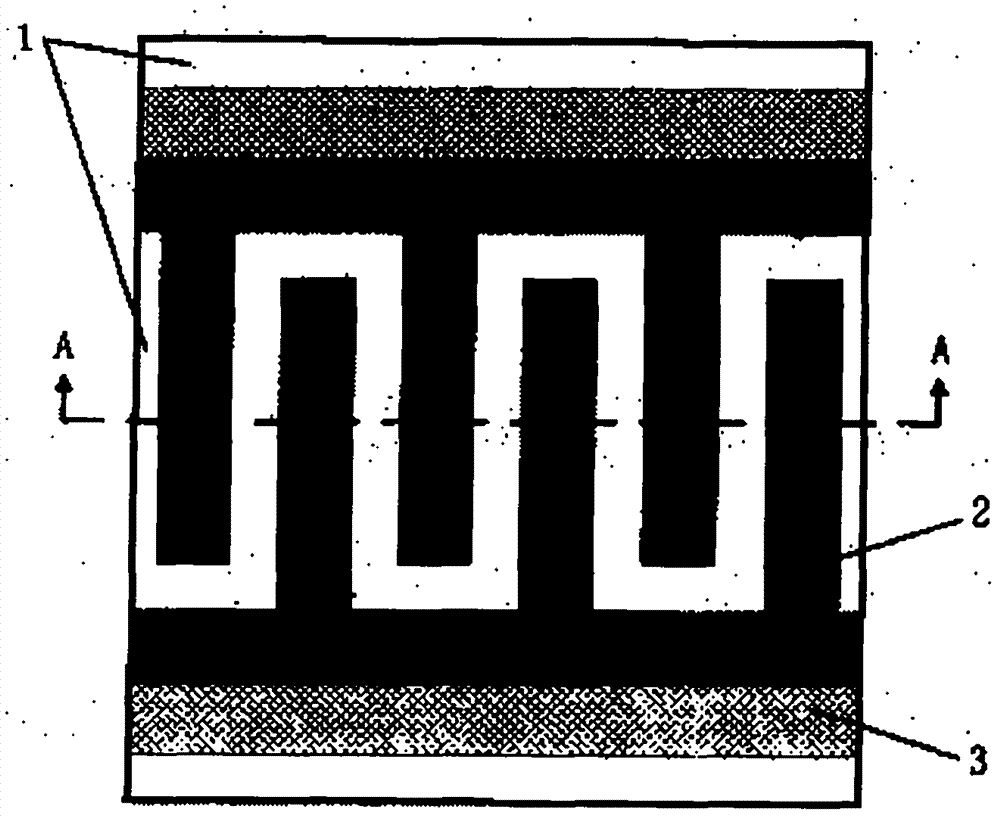

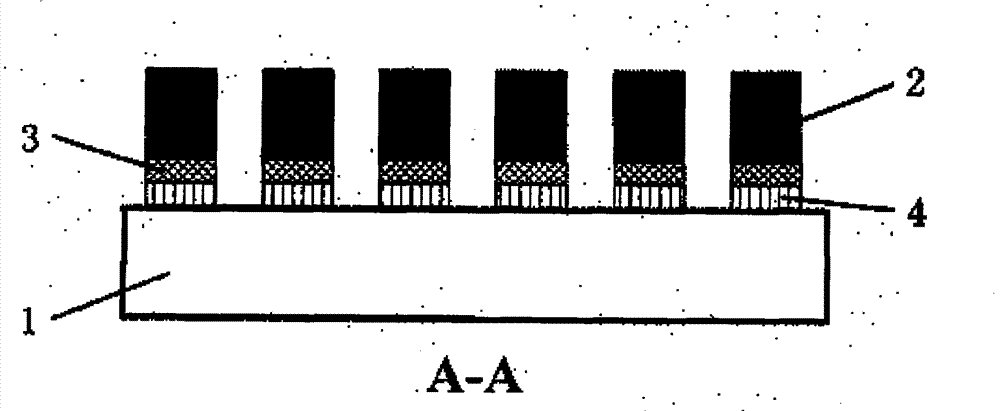

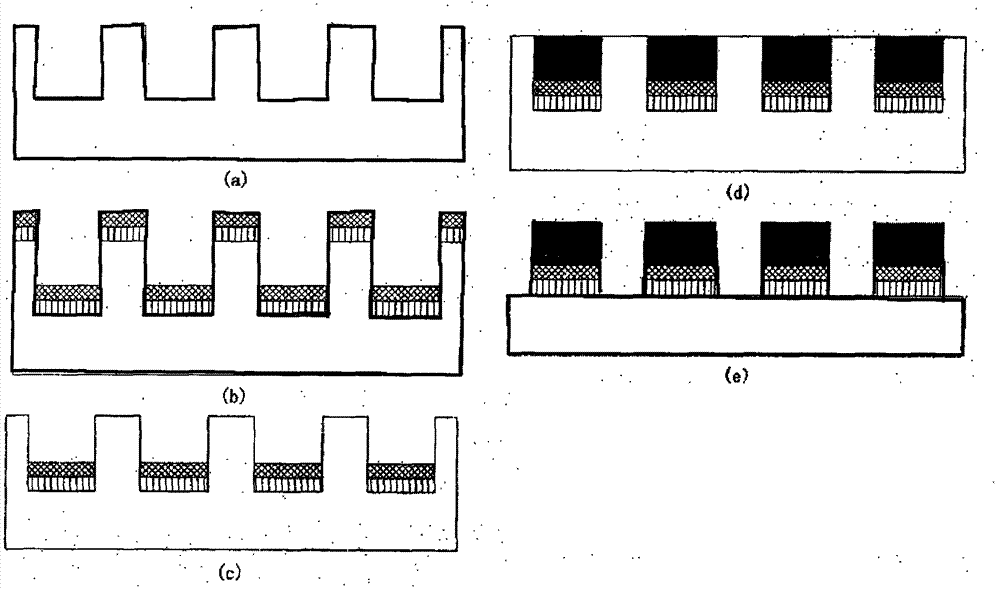

[0021] figure 1 A schematic diagram of the electrode structure of a three-dimensional micro-supercapacitor showing a supercapacitor, figure 1 a is the top view of figure 2 A cross-sectional schematic diagram of electrode A-A of a three-dimensional micro-supercapacitor that is a supercapacitor. The figure shows the finger-type electrode structure, which is a silicon dioxide insulating layer 4, a metal current collection and extraction layer 3, and an electrode active material 2 on a silicon substrate 1, and a supercapacitor with a three-dimensional structure is formed by micromachining. electrode. On the one hand, its advantage is that it can be extended to three dimensions, and can be easily scaled down or enlarged. On the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com